Bridge pier VSR (vibration stress relief) method for steel structural bridge

A technology of vibration aging and steel structure, which is applied in the field of vibration aging, which can solve the problems of hidden bridge quality problems, high technical difficulty, strong rigidity, etc., and achieve the effect of solving hidden dangers of bridge quality problems, avoiding pier rollover, and eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

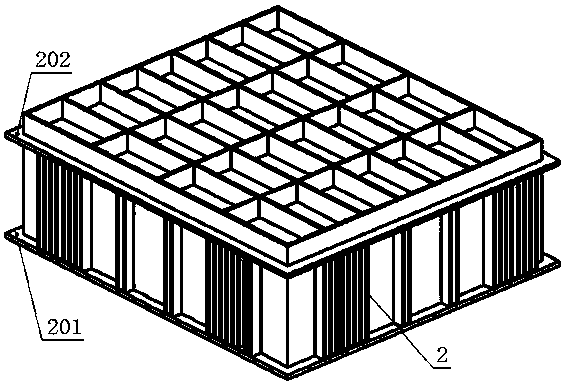

[0035] figure 1 Shown is the pier 2 of the steel structure bridge, the lower frame girder 201 is arranged at the lower part of the pier 2, and the upper frame girder 202 is arranged at the upper part of the pier 2, and the pier 2 is a cube whose length×width×height are 10858mm×10858mm×3450mm , with a weight of 500.3 tons, welded by 40 mm thick steel plates; the lower frame beam 201, the upper frame beam 202, the top surface of the pier 2 and the bottom surface of the pier 2 are arranged in parallel.

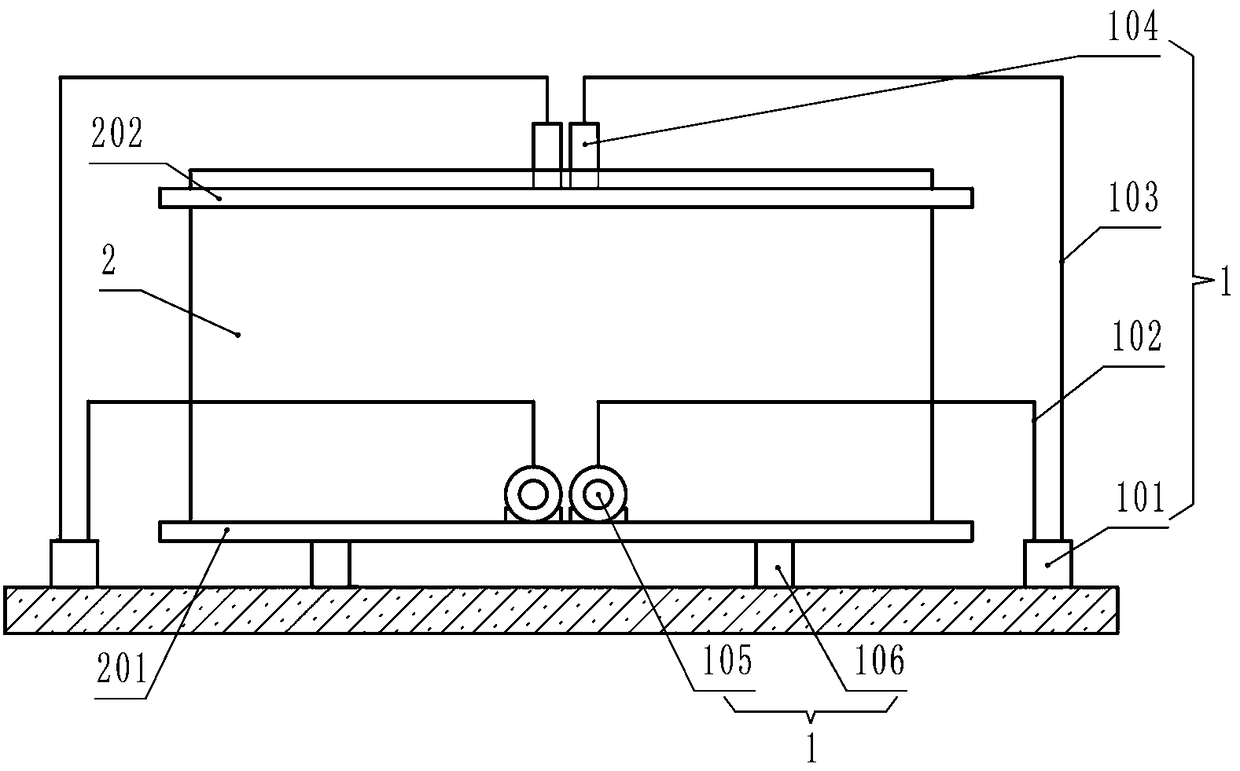

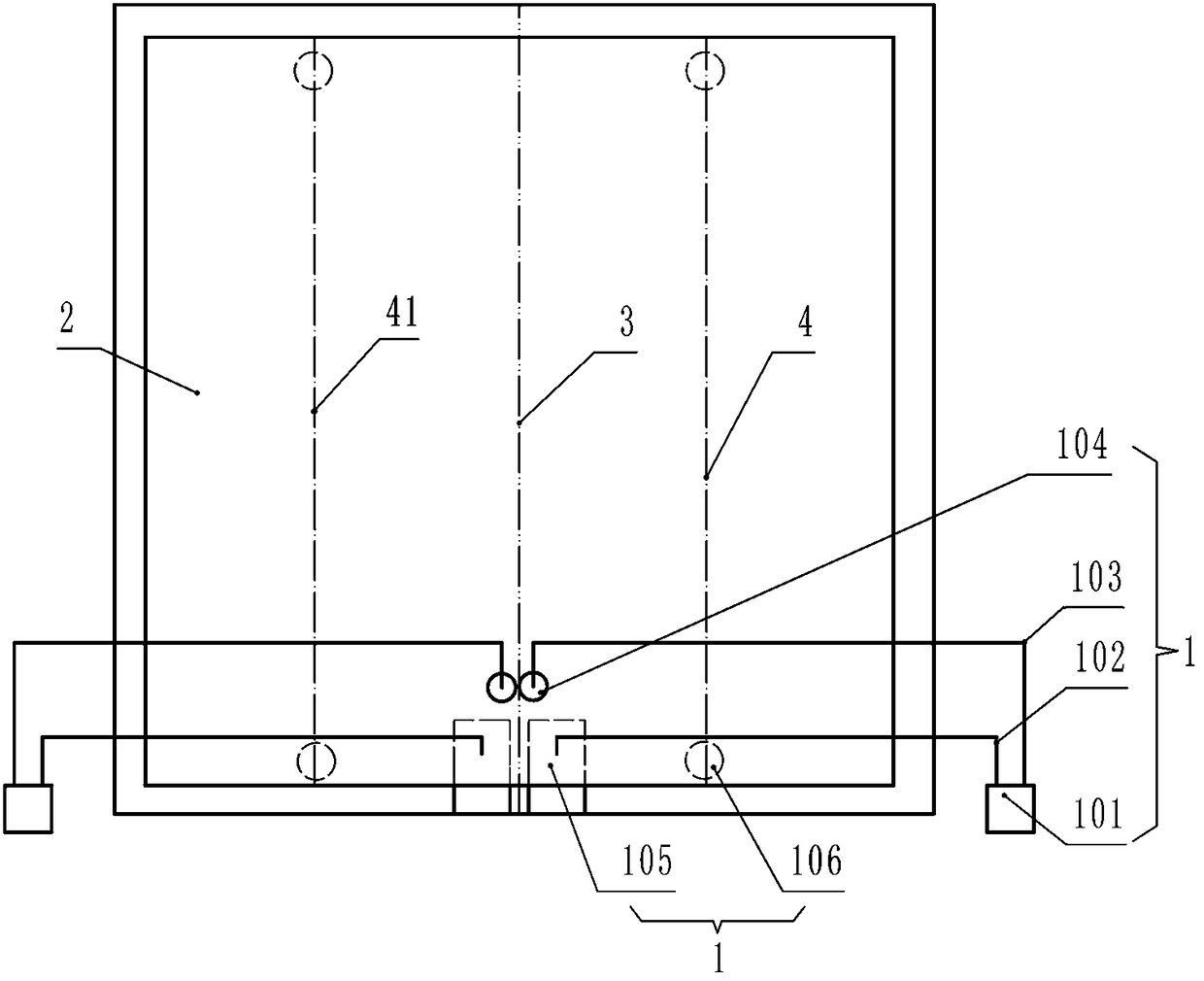

[0036] In this embodiment, the vibration aging method for the pier 2 of this steel structure bridge is: use two vibration aging equipment 1, the rated excitation force of the two vibration aging equipment 1 is 50KN, and the rated excitation frequency is 133.33HZ; Every vibration aging device 1 has a controller 101, a vibrator 105, a vibrator 104 and four support pads, the controller 101 is connected with the vibrator 105 through the vibrator wire 102, and the controller 101 passe...

Embodiment 2

[0046] In the first step, the pier 2 is hoisted and placed horizontally on four support pads 106. The four support pads 106 in this embodiment are four cylindrical rubber pads, and the diameter of each cylindrical rubber pad is 300 mm. The thickness is 200 mm, the modulus of elasticity is 1Mpa, and Poisson's ratio is 0.7;

[0047] The third step is to fix the exciters 105 of the two vibration aging equipment 1 on the projection line of the resonance peak of the lower frame beam 201 on the upper end surface of the lower frame beam 201, because the lower frame beam 201 is arranged parallel to the top surface of the pier 2 Therefore, the projection line of the formant peak of the lower frame beam 201 on the upper end surface of the lower frame beam 201 is parallel to the projection line 3 of the formant peak of the upper frame beam 02 of the pier 2 on the top surface of the pier 2; To be adjacent to the projection line 3; the motor rotation direction of each vibrator 105 is set i...

Embodiment 3

[0050] In the first step, the pier 2 is hoisted and placed horizontally on four support pads 106. The four support pads 106 in this embodiment are four cylindrical rubber pads, and the diameter of each cylindrical rubber pad is 500 mm. The thickness is 500mm, the modulus of elasticity is 2Mpa, and Poisson's ratio is 1.5;

[0051] The third step is to fix the exciters 105 of the two vibration aging equipment 1 on the projection line of the resonance peak peak of the lower frame beam 201 on the upper end surface of the lower frame beam 201, because the lower frame beam 201 is arranged parallel to the top surface of the pier 2 Therefore, the projection line of the formant peak of the lower frame beam 201 on the upper end surface of the lower frame beam 201 is parallel to the projection line 3 of the formant peak of the upper frame beam 02 of the pier 2 on the top surface of the pier 2; To be adjacent to the projection line 3; the motor rotation direction of each vibrator 105 is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com