Method for moulding closed-rib by continuous rolling and cold bending and device for implementing the same

A forming method and cold bending technology, applied in the direction of metal rolling, etc., to achieve the effect of improving production efficiency, easy implementation, and no damage to surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

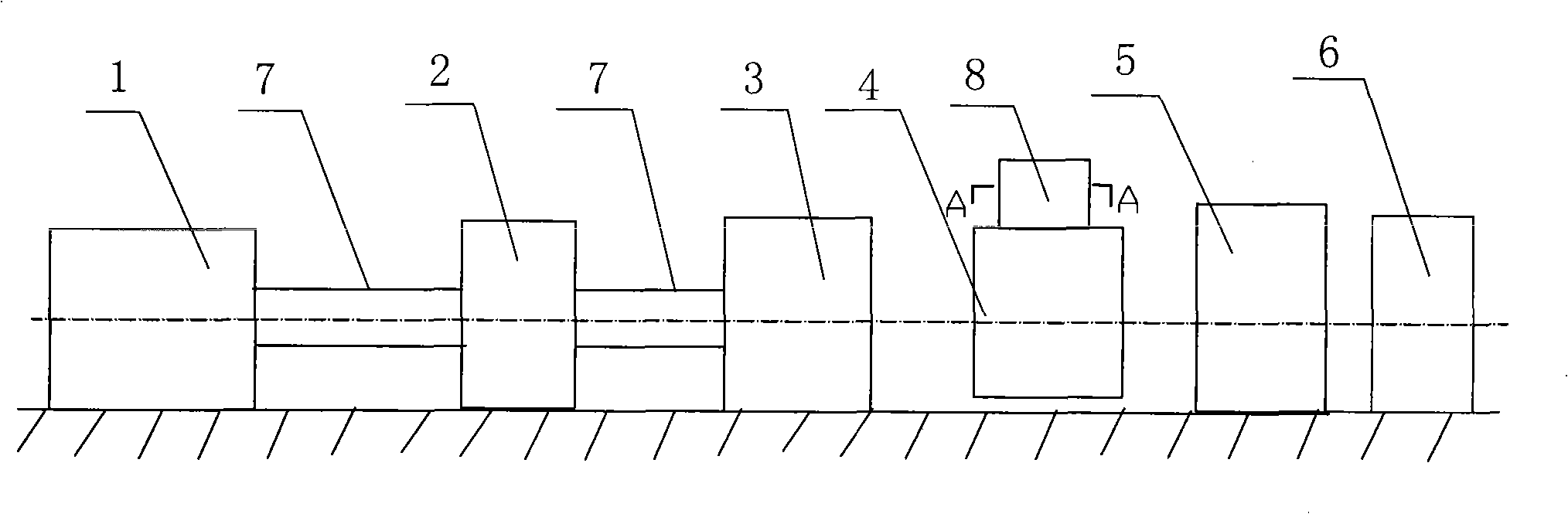

[0029] A rolling continuous cold-bending closed rib forming method, the steps:

[0030] 1) Carry out coil uncoiling;

[0031] 2) carry out looper storage;

[0032] 3) Use 10 rolls for the first roll cold bending;

[0033] 4) Use a planer to plan the groove of the steel strip for the first roll cold bending, and control the running speed of the steel strip at 6 m / min;

[0034] 5) Use 2 rolls for the second rolling cold bending;

[0035] 6) Carry out sawing to length and set aside.

Embodiment 2

[0037] A rolling continuous cold-bending closed rib forming method, the steps:

[0038] 1) Carry out coil uncoiling;

[0039] 2) carry out looper storage;

[0040] 3) Use 12 rolls for the first roll cold bending;

[0041] 4) Use 2 edge planers to plan the bevel of the steel strip for the first roll cold bending, and control the running speed of the steel strip at 8 m / min;

[0042] 5) Use 3 rolls for the second rolling cold bending;

[0043] 6) Carry out sawing to length and set aside.

Embodiment 3

[0045] A rolling continuous cold-bending closed rib forming method, the steps:

[0046] 1) Carry out coil uncoiling;

[0047] 2) carry out looper storage;

[0048] 3) 14 rolls are used for the first roll cold bending;

[0049] 4) Use 2 edge planers to plan the bevel of the steel strip for the first roll cold bending, and control the running speed of the steel strip at 13 m / min;

[0050] 5) Use 2 rolls for the second rolling cold bending;

[0051] 6) Carry out sawing to length and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com