Deburring machine of grinding belt in tensioning swing type

A deburring machine and swing-type technology, which is applied to abrasive belt grinders, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problem that deburring equipment cannot meet the task of deburring large-scale punching, and cannot be used to process high-quality motors Problems such as punching and burrs cannot be removed as scheduled, to achieve the effect of wide processing range, safe and reliable performance, and economical cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

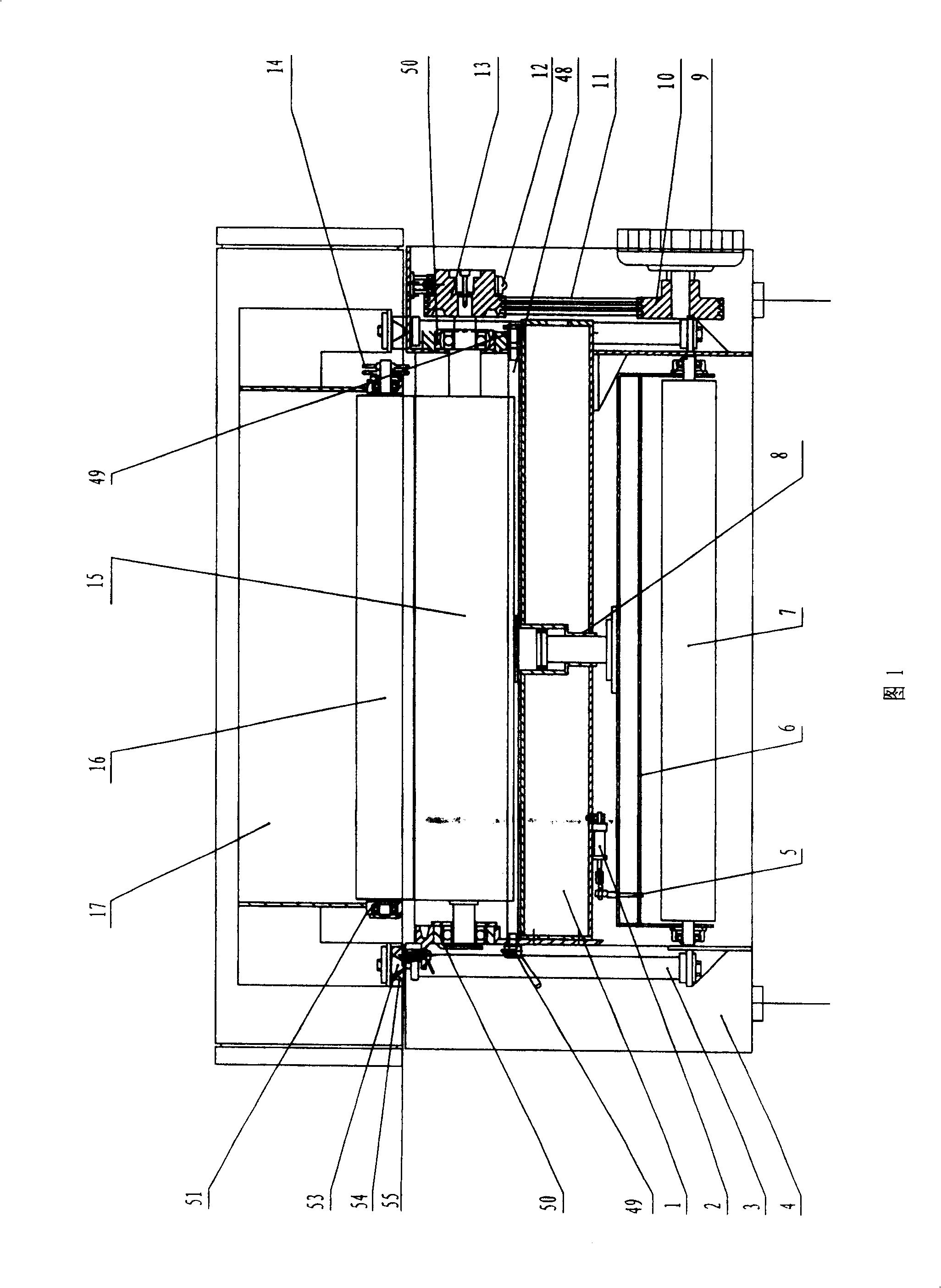

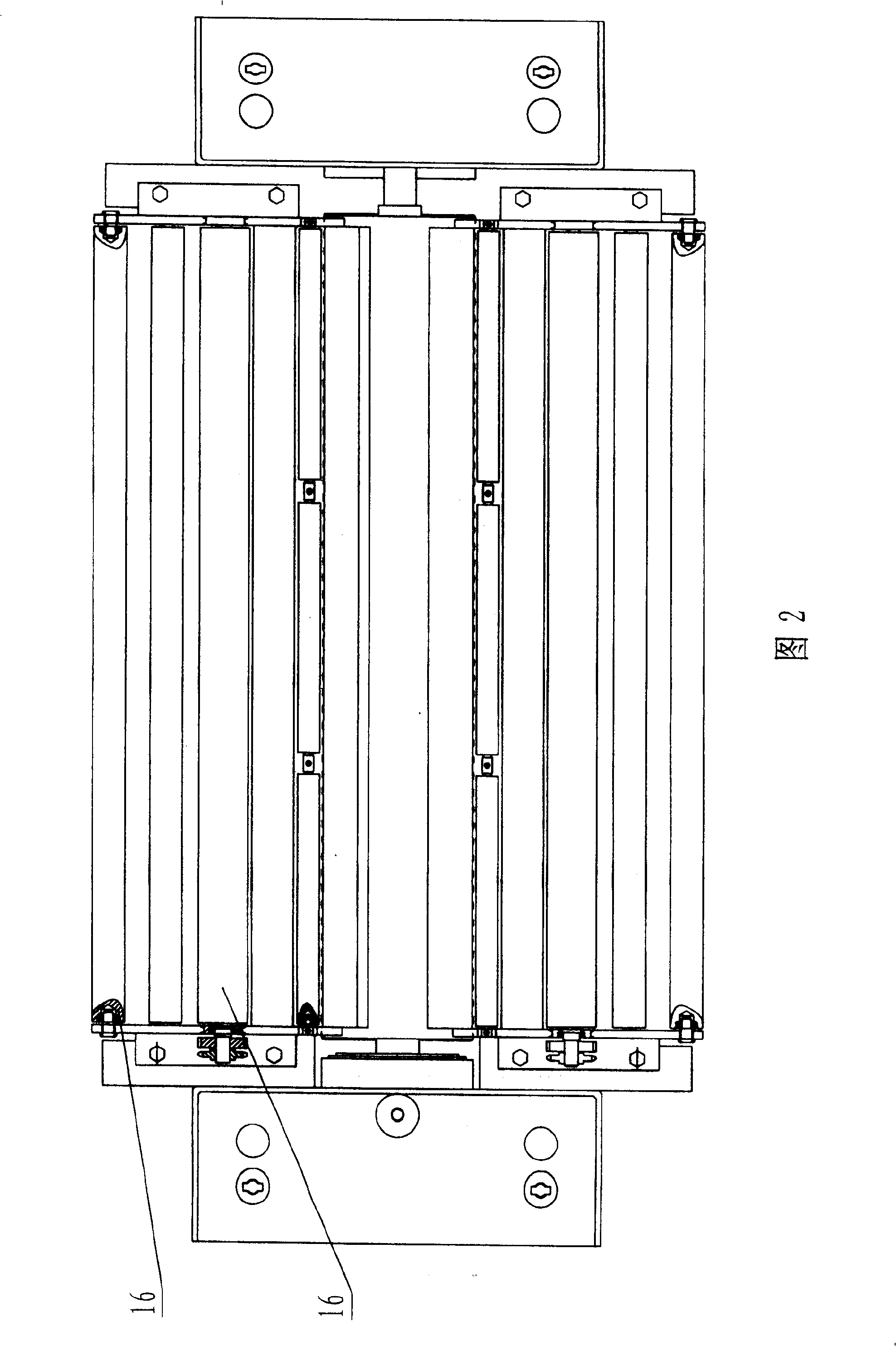

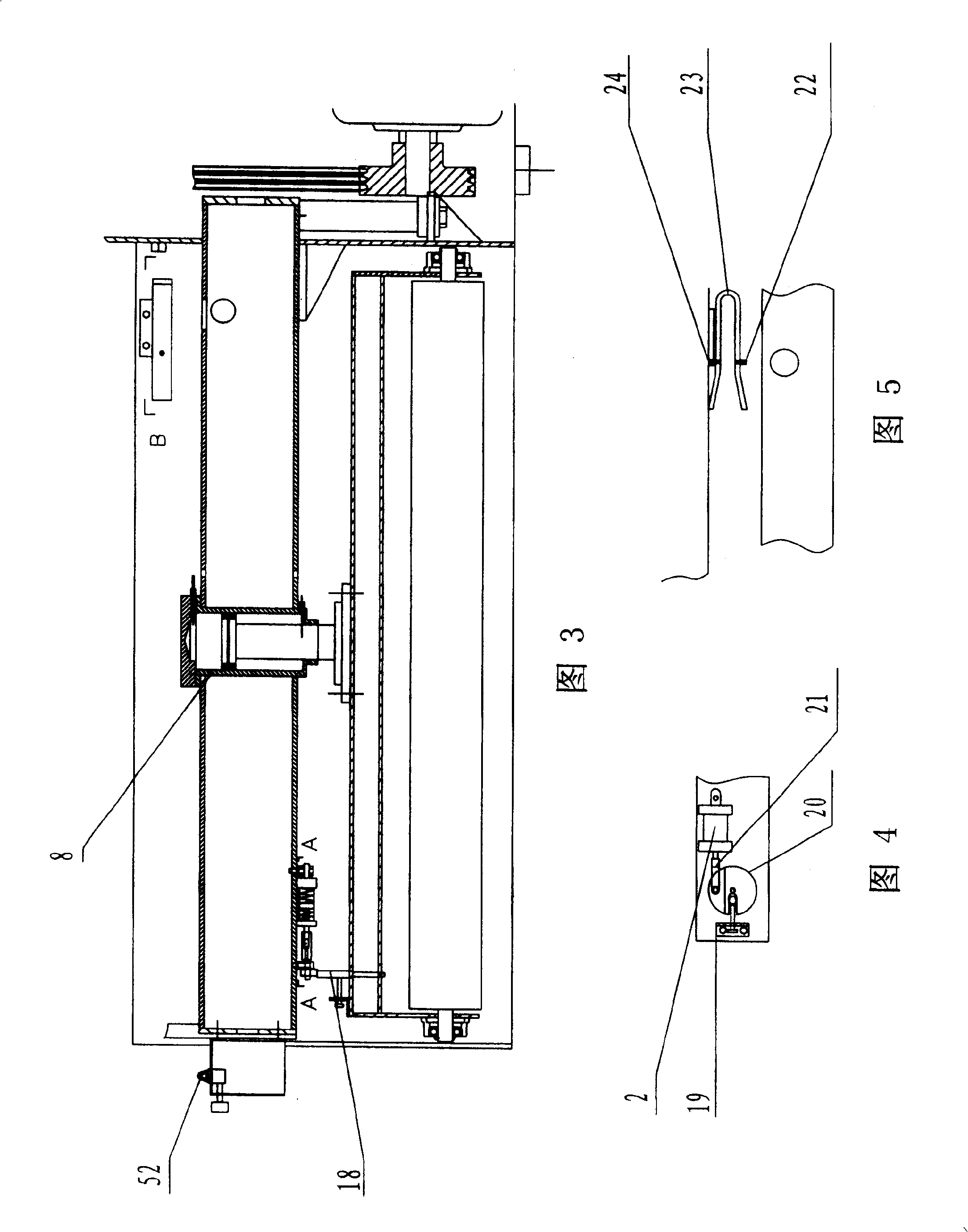

[0029] Embodiment: As shown in Figure 1 and Figure 2, the pressing device is installed on the main machine, and the feeding and discharging devices are respectively installed on the front and back of the main machine. Connection, the pneumatic system is connected with each cylinder on the main machine; it is mainly composed of bed 4, main pressing steel roller 16, main rubber roller 15, large beam 1, swing mechanism 5, tensioning cylinder 8, tensioning roller 7. Composed of small beam 6, motor 9, V-belt 11, sprocket 14, abrasive belt and brake 12, the left and right sides of the bed 4 are respectively equipped with lifting cylinders 3 connected with the pressing device, and the lower right side of the bed 4 There is a motor 9, which is connected with the brake pulley 13 on the brake 12 through the V-belt 11, the brake pulley 13 is installed on the shaft end of the main rubber roller 15, and the main pressure steel roller 16 is arranged on the main rubber roller Above 15, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com