Clean plate automatic conveying, flipping and capping device

A technology of automatic conveying and flipping covers, which is applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of staff fatigue, increased labor intensity, and low production efficiency, so as to reduce labor intensity, save manpower, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

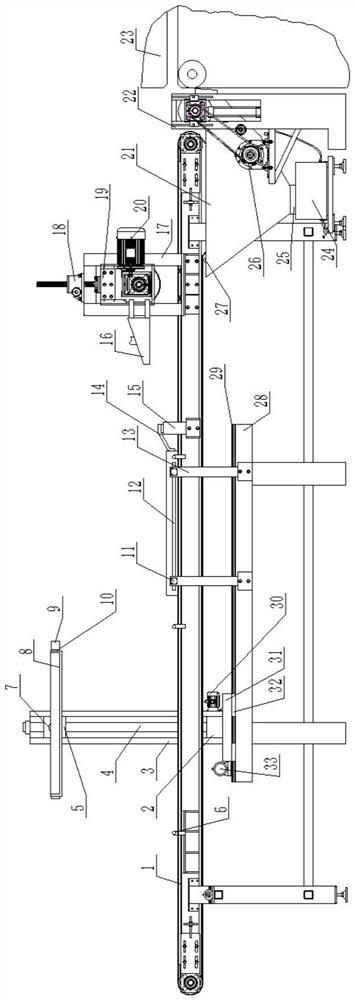

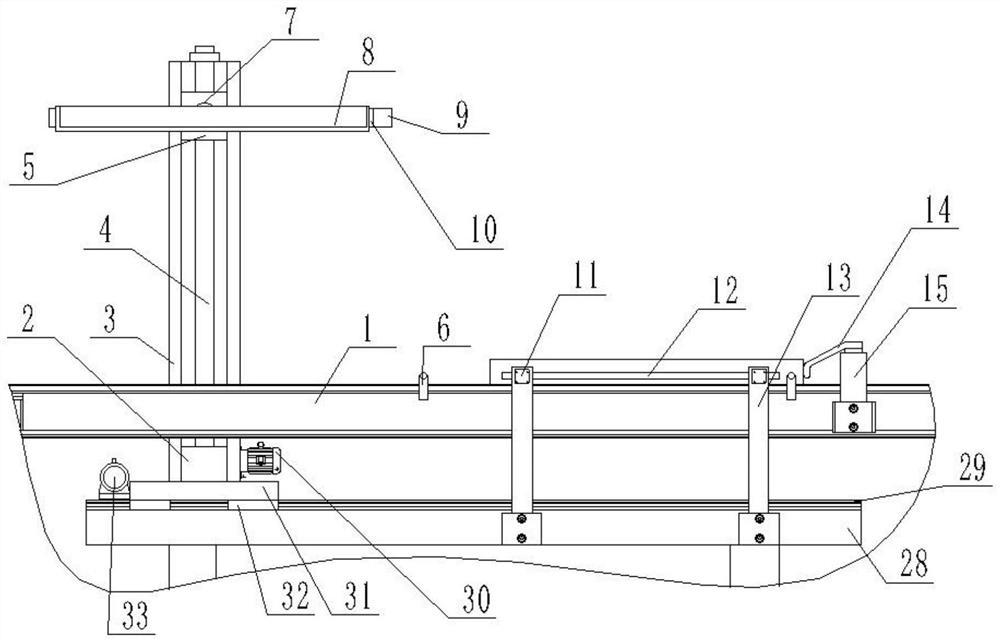

[0034] Example 1, as figure 1 , 2 , 5 and Image 6 As shown in the figure, the present invention is an automatic conveying, flipping and capping device for clean boards, including a conveyor 1 arranged at the left end of the pressing device, and a horizontal guide rail frame 28 is provided at the front and rear sides of the left end of the conveyor 1. The top of the guide rail frame 28 A horizontal slide rail 29 is fixed, the slide rails 29 on both sides are provided with translation sliders 32, the translation sliders 32 on the front and rear sides are fixedly connected by a connecting base plate 31, and the base plate is provided with a driving device for driving its left and right movement, The tops of the connecting base plates 31 at the front and rear ends are fixed with supporting frames 3 , and the supporting frames 3 on the front and rear sides are provided with lifting sliders 5 that can slide up and down. 7 is fixedly connected by a U-shaped bracket plate 9, the op...

Embodiment 2

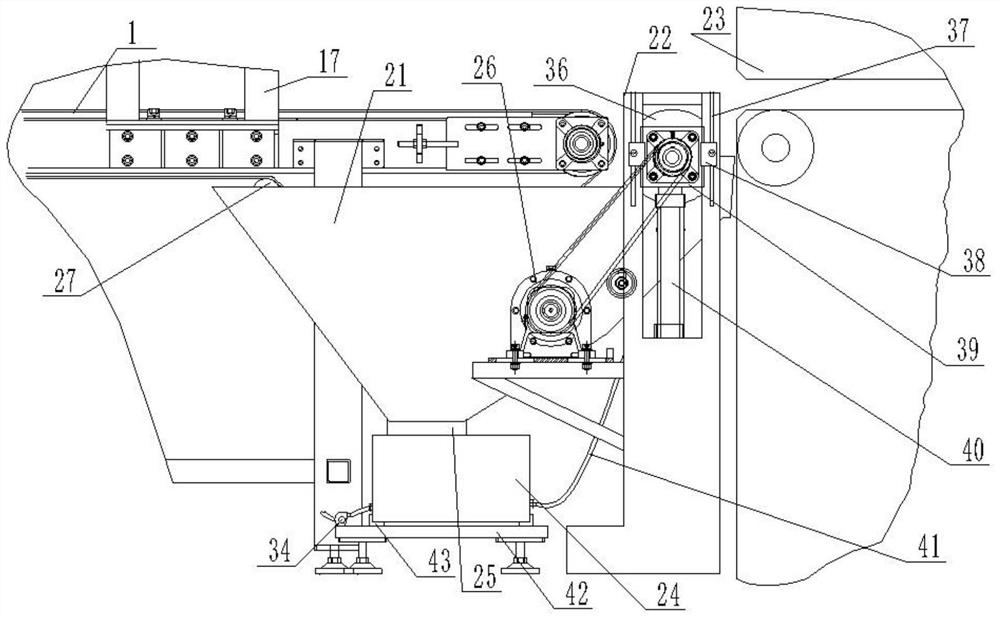

[0038] Example 2, as Figure 1-12 As mentioned above, on the basis of Embodiment 1, the front and rear sides between the conveyor 1 and the pressing device 23 are provided with support columns 22, and the support columns 22 on the front and rear sides are provided with adjustment sliders 40 that can slide up and down, The bottom of the adjustment slider 40 is fixed with an adjustment cylinder 40, and a lower cleaning roller 36 is rotatably installed between the adjustment sliders 40 on both sides through a bearing seat. The lower cleaning roller 36 is provided with lower cleaning brushes, and one end of the lower cleaning roller 36 is connected with a The cleaning drive device is provided with a dust receiving box 21 below the lower cleaning bristles.

[0039] The outer wall of the support column 22 is provided with a T-shaped chute 37 along the vertical direction, the T-shaped chute 37 is provided with a T-shaped bolt, the T-shaped bolt is connected with a locking block 39, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com