Tire

A tire and tread technology, applied in pneumatic tires, special tires, tire parts, etc., can solve problems such as reducing tire fuel efficiency, achieve good fuel efficiency, improve ride comfort and dry road handling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

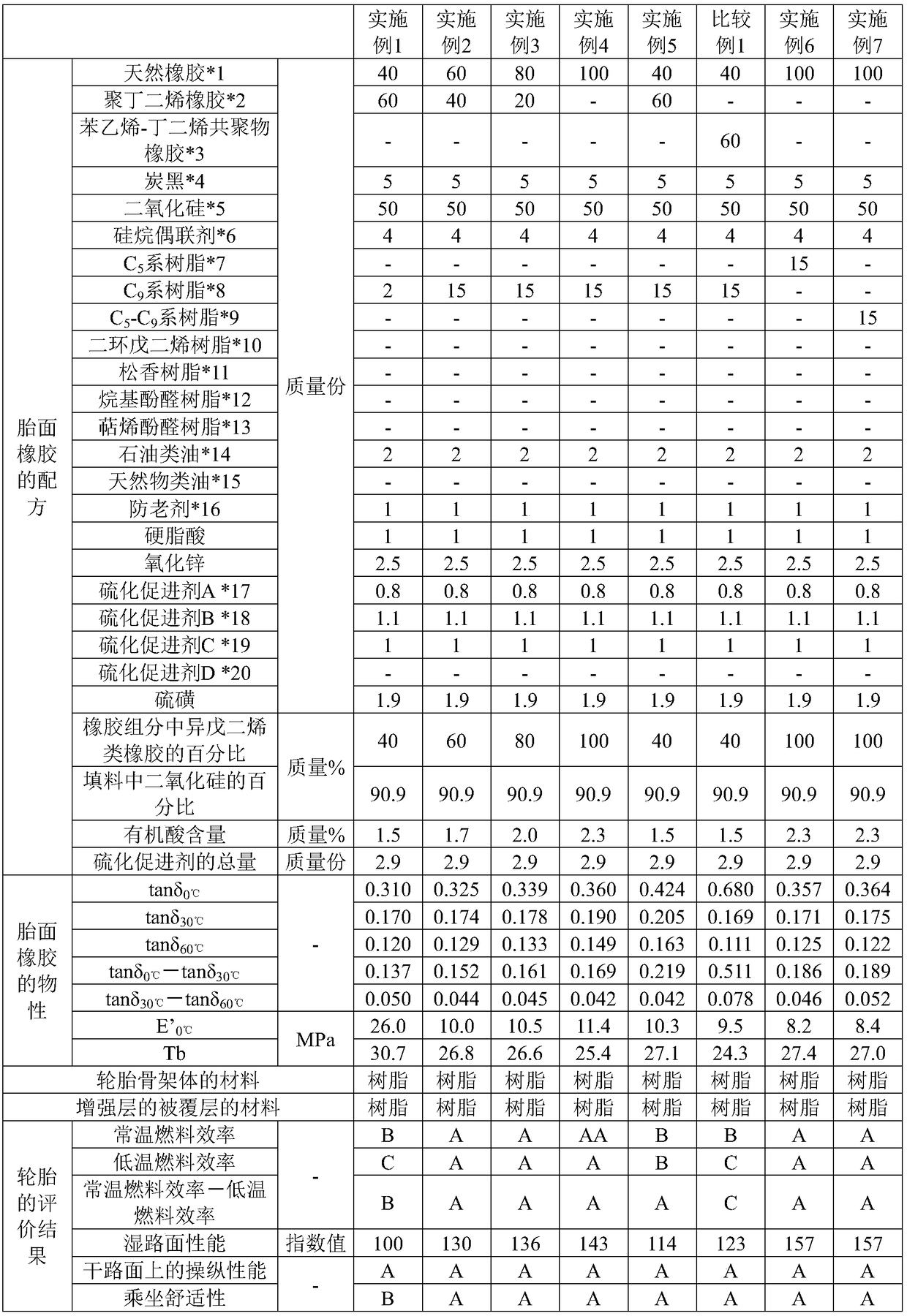

Embodiment 1-19 and comparative example 1-4

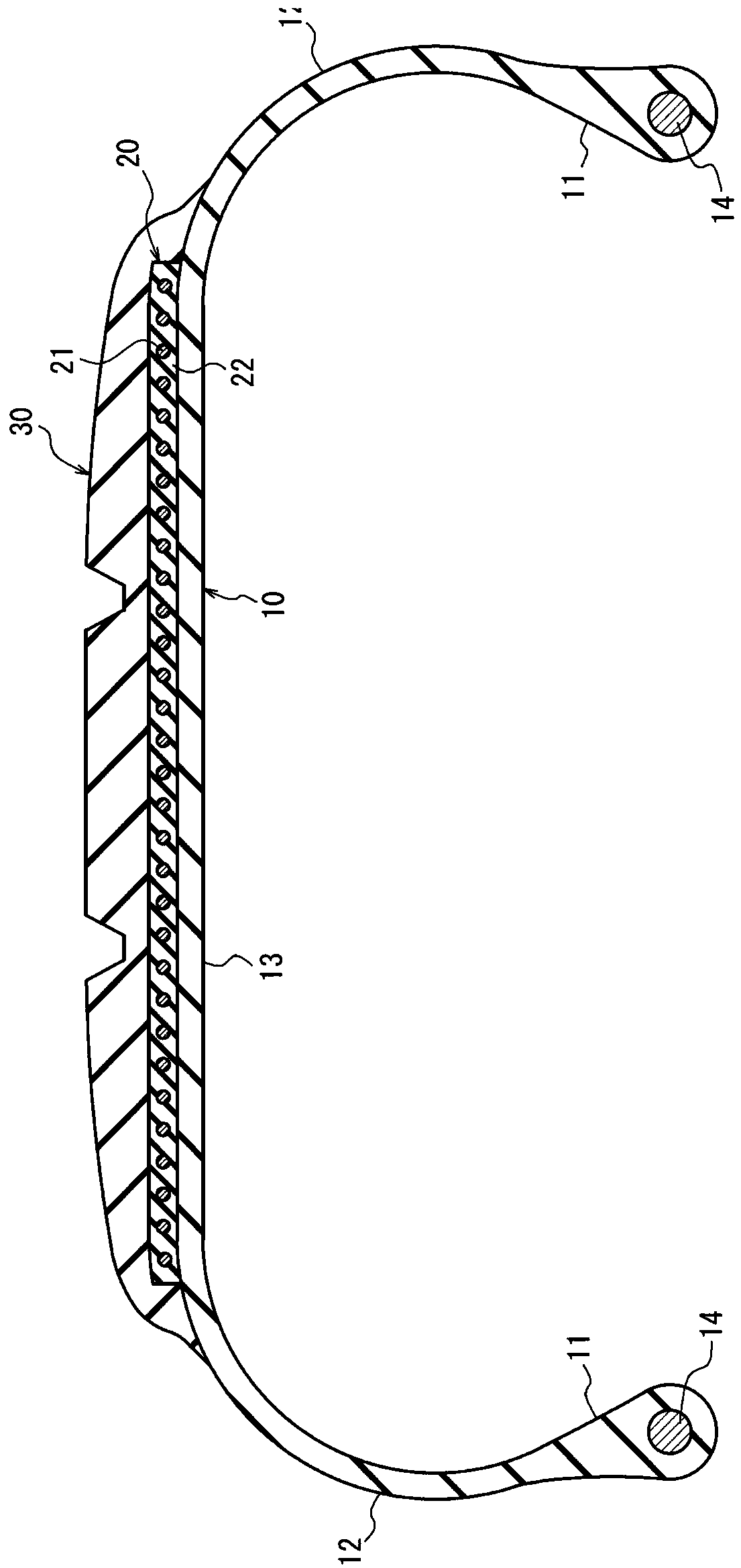

[0145] According to the second embodiment in JP 2012-046030 A (PTL 3), a tire frame (carcass) is produced by preparing a half body of the tire frame by injection molding using a polyamide-based thermoplastic elastomer as a resin material, The halves are placed opposite each other and joined by applying pressure at a temperature at least as high as the melting point of the polyamide-based thermoplastic elastomer used.

[0146] Next, a reinforcing layer is provided on the outer side in the tire radial direction of the tire frame by helically winding a steel cord coated with a thermoplastic elastomer in the tire circumferential direction.

[0147] Then, a tread rubber formed from the rubber compositions of the formulations shown in Tables 1 to 3 was provided on the outer side in the tire radial direction of the reinforcing layer, followed by vulcanization. Through this process, tires (pneumatic tires) are manufactured.

[0148] The manufactured tire frame had a thickness of 2 mm...

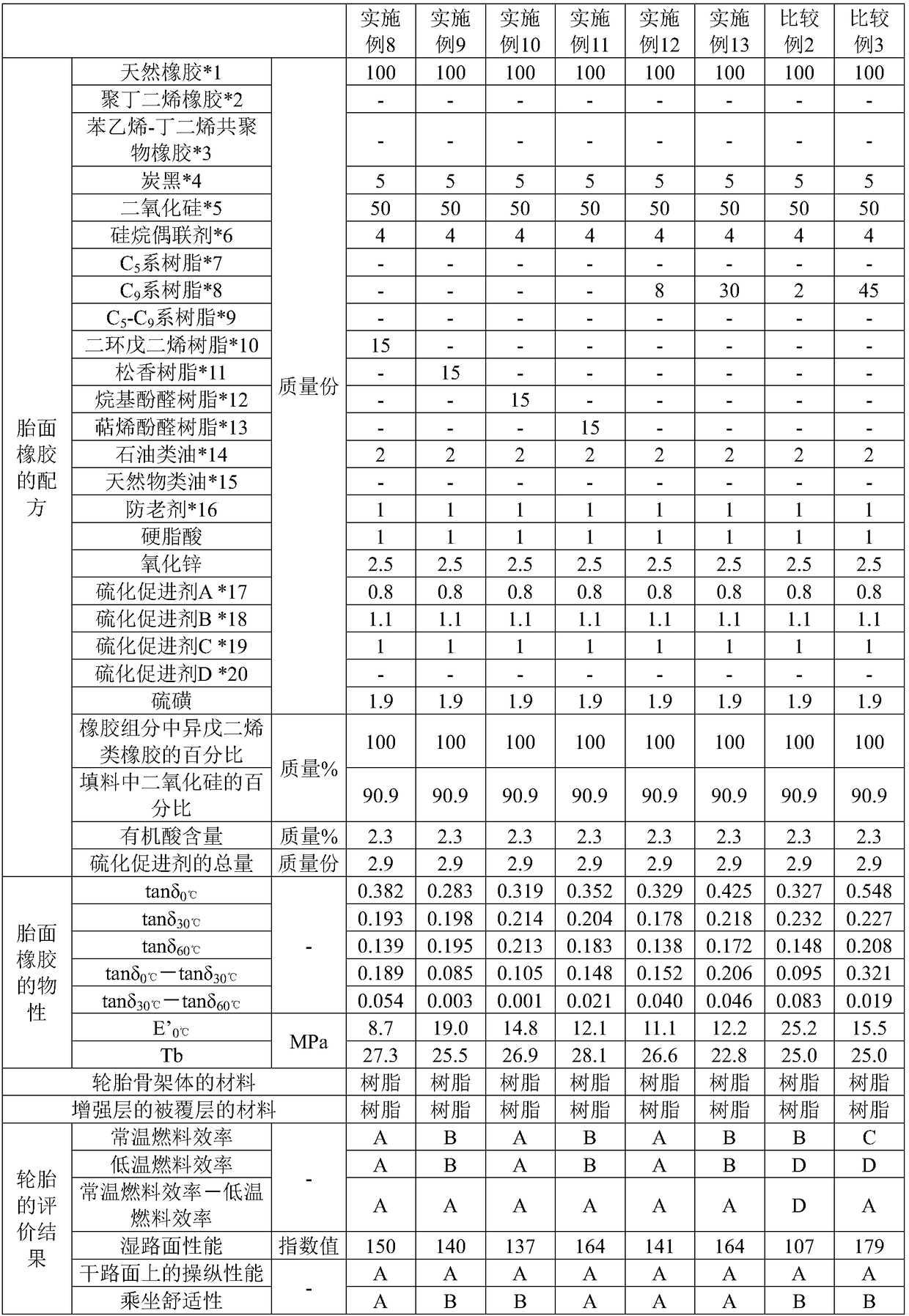

Embodiment 24-31

[0229] In the same manner as in Examples 1-19 and Comparative Examples 1-4, a tire frame (carcass) was produced, and the reinforcing layer was wound by spirally winding a steel cord covered with a thermoplastic elastomer in the tire circumferential direction. The wire is arranged on the outer side of the tire frame in the tire radial direction.

[0230] Then, a tread rubber formed from the rubber composition of the formulation shown in Table 5 was provided on the outer side in the tire radial direction of the reinforcing layer, followed by vulcanization. Through this process, tires (pneumatic tires) are manufactured.

[0231] In order to measure the organic acid content in the rubber composition used in the tread rubber, the loss tangent (tanδ) and the storage modulus (E') of the tread rubber, and the tensile strength (Tb) of the tread rubber, the aforementioned method.

[0232] The manufactured tires were evaluated by the aforementioned methods in order to evaluate fuel eff...

Embodiment 32-50 and comparative example 7-10

[0246] The tire is manufactured by manufacturing a tire frame body (carcass) mainly formed of rubber according to a standard method, and providing a reinforcing layer on the tire frame by spirally winding steel cords coated with a thermoplastic elastomer in the tire circumferential direction The outer side in the tire radial direction of the body, and further provided the tread rubber formed of the rubber compositions of the formulations shown in Tables 6-8 on the outer side in the tire radial direction of the reinforcing layer.

[0247] Note: The covering layer of the steel cord in the reinforcing layer is formed of a thermoplastic elastomer, and the percentage of the resin material therein is 100% by mass. The thermoplastic elastomer used in the covering layer of the steel cord was a product "UBESTA XPA9055X1" (polyamide-based thermoplastic elastomer) manufactured by Ube Industries, Ltd.

[0248] In order to measure the organic acid content in the rubber composition used in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com