Tire

A technology of tires and skeletons, applied in pneumatic tires, special tires, tire parts and other directions, can solve the problems of difficult to achieve pressure resistance, internal pressure resistance and rigidity, and achieve the effect of excellent adhesion and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0225] The following is a description of a first embodiment according to the present invention with reference to the drawings.

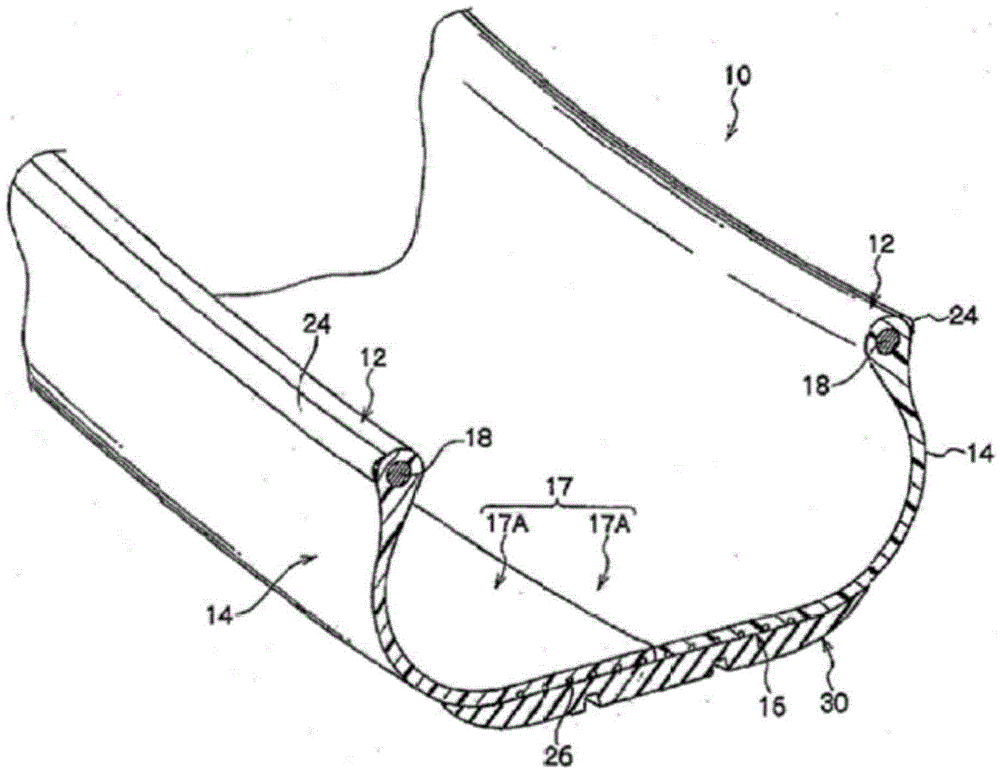

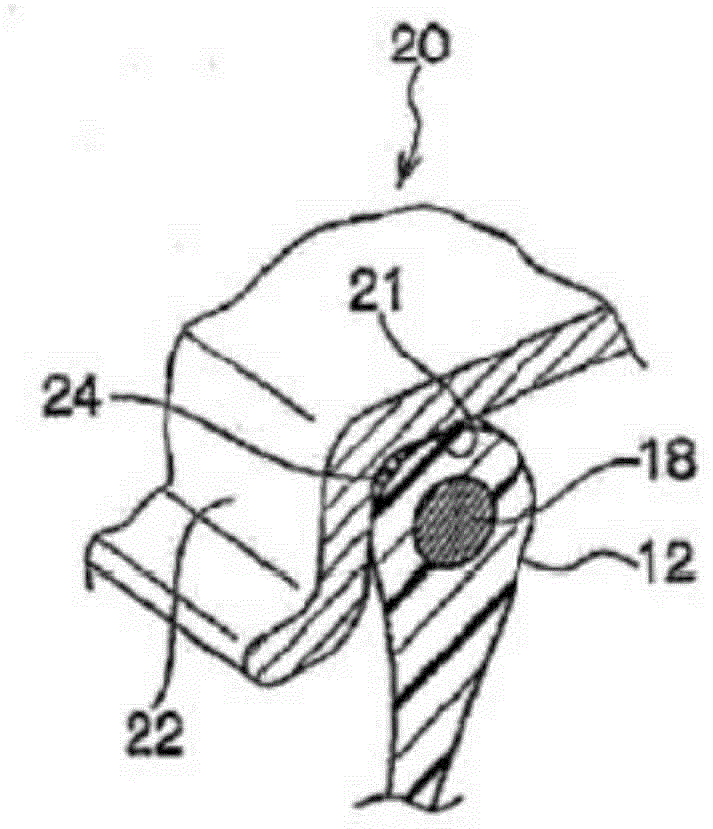

[0226] The following is a description of the tire 10 of the present embodiment. Figure 1A A partial cross-sectional perspective view for illustrating a tire according to an embodiment of the present invention. Figure 1B is the cross section of the bead portion attached to the rim. As shown in FIG. 1, a tire 10 according to an embodiment of the present invention exhibits substantially the same cross-sectional shape as that of an ordinary conventional rubber-made pneumatic tire. In the present embodiment, the reinforcing cord 26 uses a steel cord having a twisted structure as a metal reinforcing cord member (tensile modulus of elasticity: 210000 MPa, elongation at break: 8%), and it serves as a core, the core The outer periphery of is covered with a covering compound comprising at least a thermoplastic resin and a specific elastomer. In the presen...

no. 2 approach

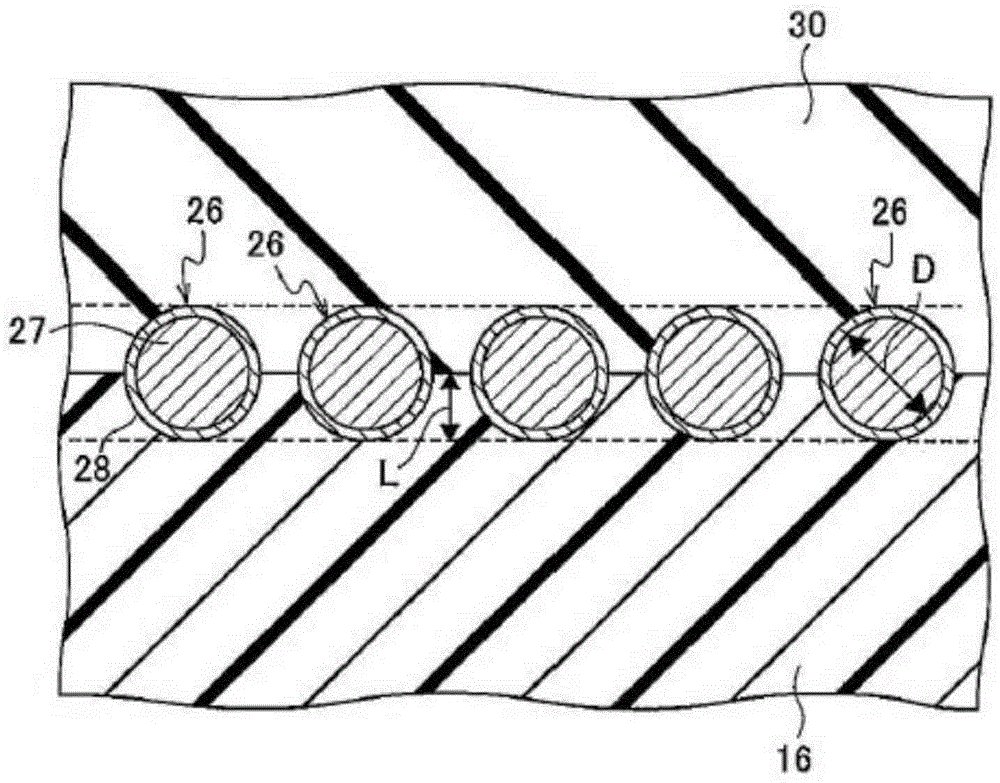

[0263] The following is a description of a second embodiment of the tire of the present invention with reference to the accompanying drawings. Figure 4 is a tire of the second embodiment taken along the tire rotation axis and showing a cross section of an embodiment including a reinforcing cord cover layer in which a metal reinforcing cord member has been buried on the crown of a tire case of the tire. according to Figure 4 As shown, the tire of the present embodiment has a reinforcing cord covering layer 29 in which steel cords 27 (metal reinforcing cord members) are embedded on the surface of the crown portion 16 of the tire case, and a tread 30 is placed on the reinforcing cord over the line covering layer 29. A tire according to the second embodiment has a configuration similar to that of the first embodiment, and the same reference numerals are attached to the configuration similar to the first embodiment except for the above points.

[0264] The tire of the second embo...

Embodiment

[0282] Hereinafter, the present invention will be explained more specifically based on examples.

[0283]

[0284] The components of the resins (including the covering mixture) listed in Table 1 were mixed (based on mass) and kneaded using a twin-screw extruder LABO PLASTOMILL50MR (trade name) manufactured by Toyo Seiki Seisaku-sho, Ltd. to obtain pellets .

[0285] The obtained pellets were pressurized by hot pressing at 200° C., and the resultant was trimmed to manufacture a sample having a size of 120 mm×120 mm and a thickness of 2.0 mm.

[0286] Each sample was die-cutting according to JIS K6251:1993 definition to prepare a dumbbell-shaped test sample (test sample No. 5).

[0287] Then use precision universal testing machine SHIMADZU AUTOGRAPH AGS-J (trade name, load 5KN) manufactured by Shimadzu Corporation, measure the tensile modulus of elasticity, elongation at break of each dumbbell-shaped test sample under the elongation speed of 200mm / min rate and tensile streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com