Pneumatic tire

A technology for pneumatic tires and bottom tires, which is applied to tire parts, tire rims, vehicle parts, etc., can solve the problems of complex manufacturing process, difficult material recycling of vulcanized rubber, and increased manufacturing costs, so as to improve the durability of the bead, improve the The effect of increased recyclability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

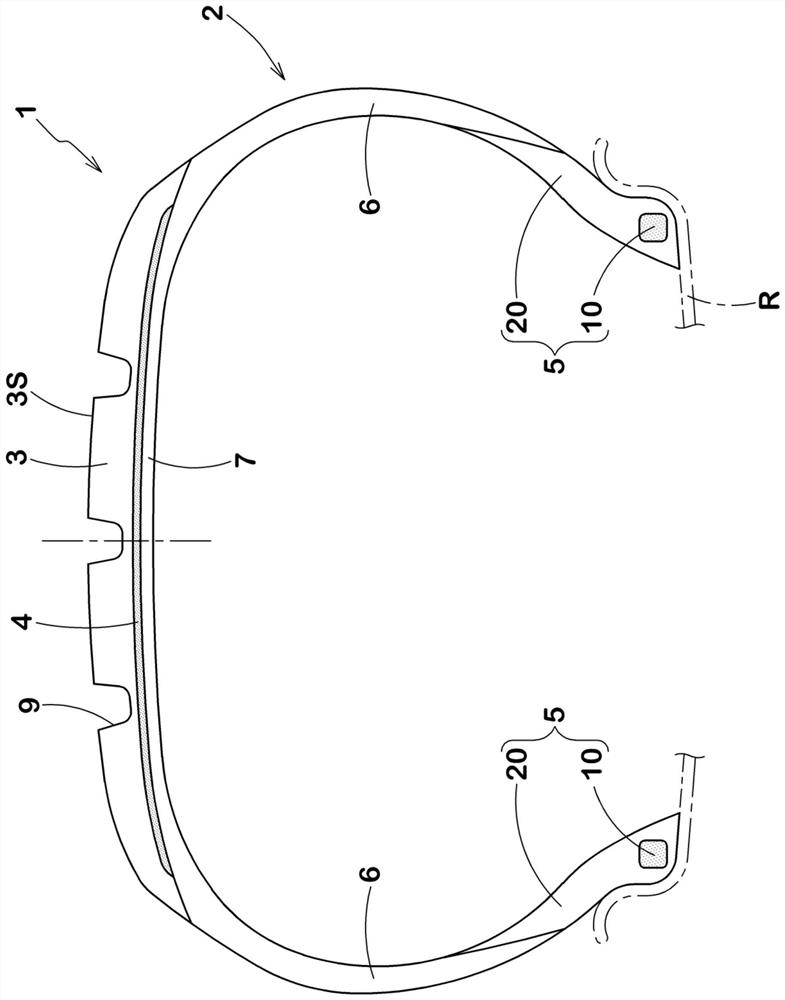

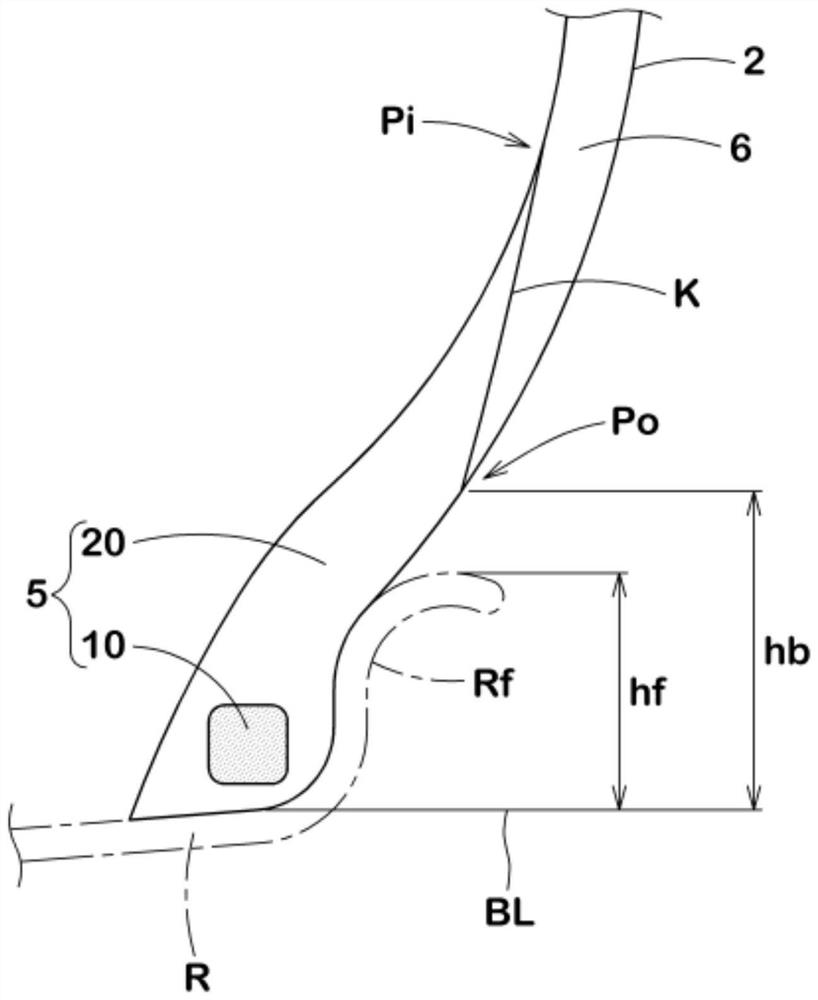

[0076] In order to confirm the effect of the present invention, according to the specification trial production of table 1 has figure 1 Passenger car tires (195 / 65R15) of the construction shown. Then, the rim assembly performance, fitting performance (fitting force of the bead portion to the rim) and productivity of each trial tire were tested.

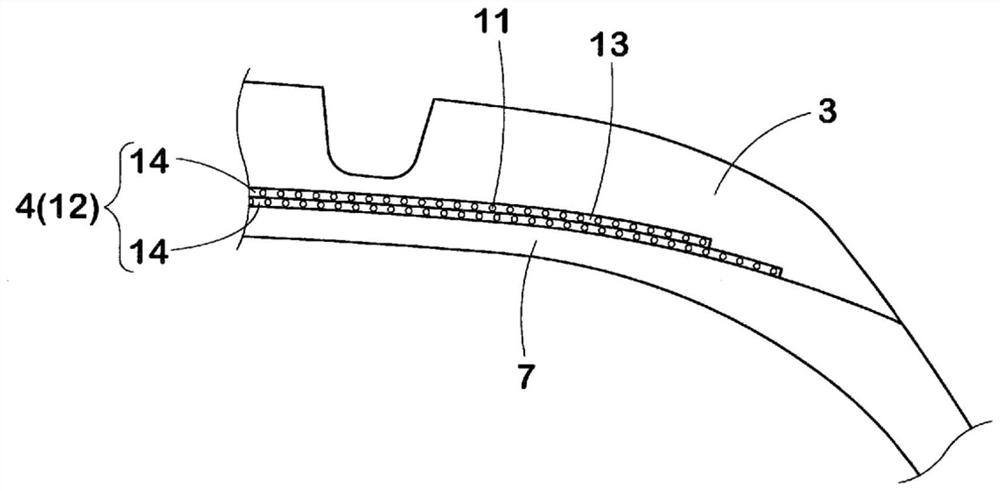

[0077] In Comparative Example 1, the structure was substantially the same as that of the Example except that the bead core was a core formed of steel cords. In addition, in Examples 1 to 6, fillers made of glass fibers were added to the bead cores.

[0078]

[0079] The presence or absence and degree of damage such as cracks in the bead portion when the tire was assembled to the rim by the automatic rim assembly machine were visually checked. Based on these inspection results, the rim assemblability was evaluated in 10 grades. The larger the index value, the better the rim assembly property.

[0080]

[0081] The Hofmann fitti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com