Tire

A technology based on tires and polyamides, applied in the direction of pneumatic tires, special tires, tires, etc., to achieve the effect of excellent rim installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0154] A tire according to a first embodiment of the present invention is described below with reference to the drawings.

[0155] The tire 10 of the present embodiment is described below.

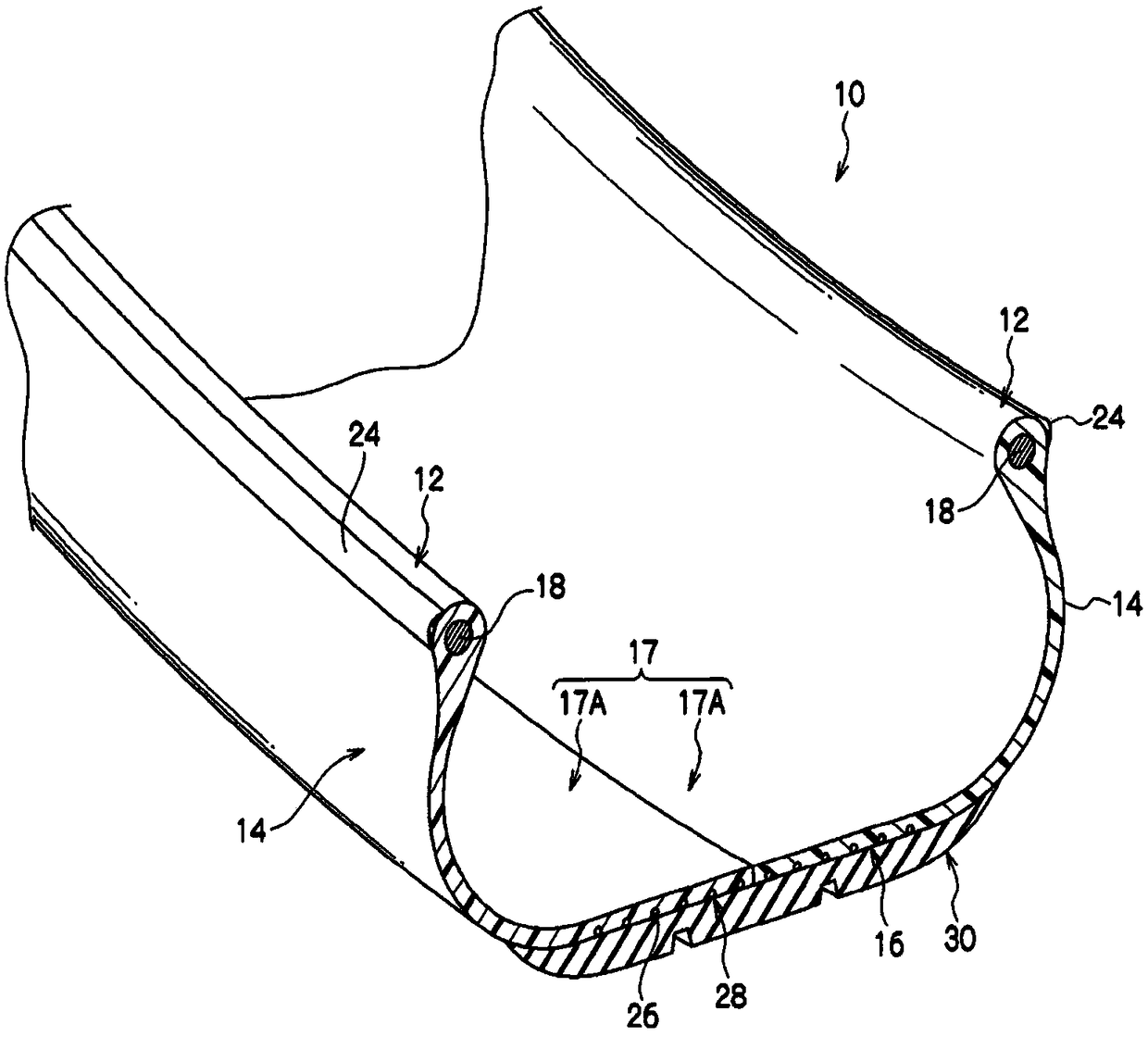

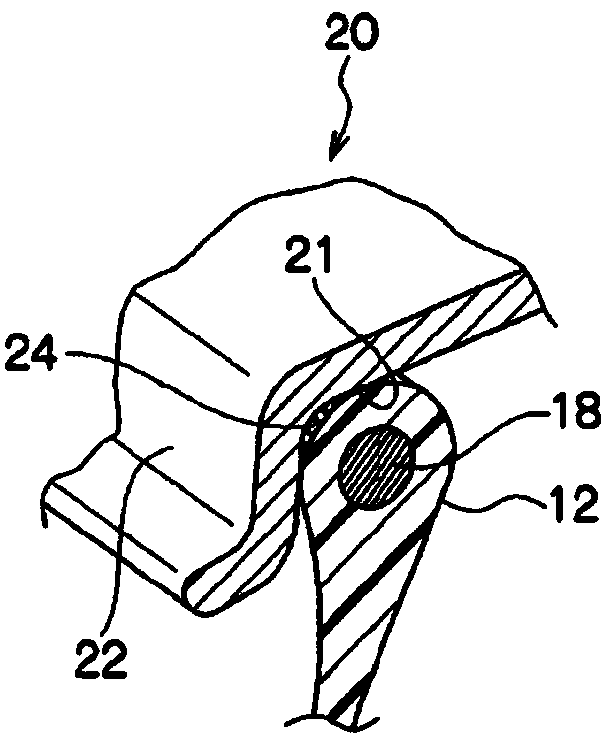

[0156] Figure 1A is a perspective view showing a section of a part of a tire according to an embodiment of the present invention. Figure 1B It is a sectional view of the bead portion attached to the rim. Such as Figure 1A As shown in , the tire 10 of the present embodiment has substantially the same cross-sectional shape as those of conventional usual rubber-made pneumatic tires.

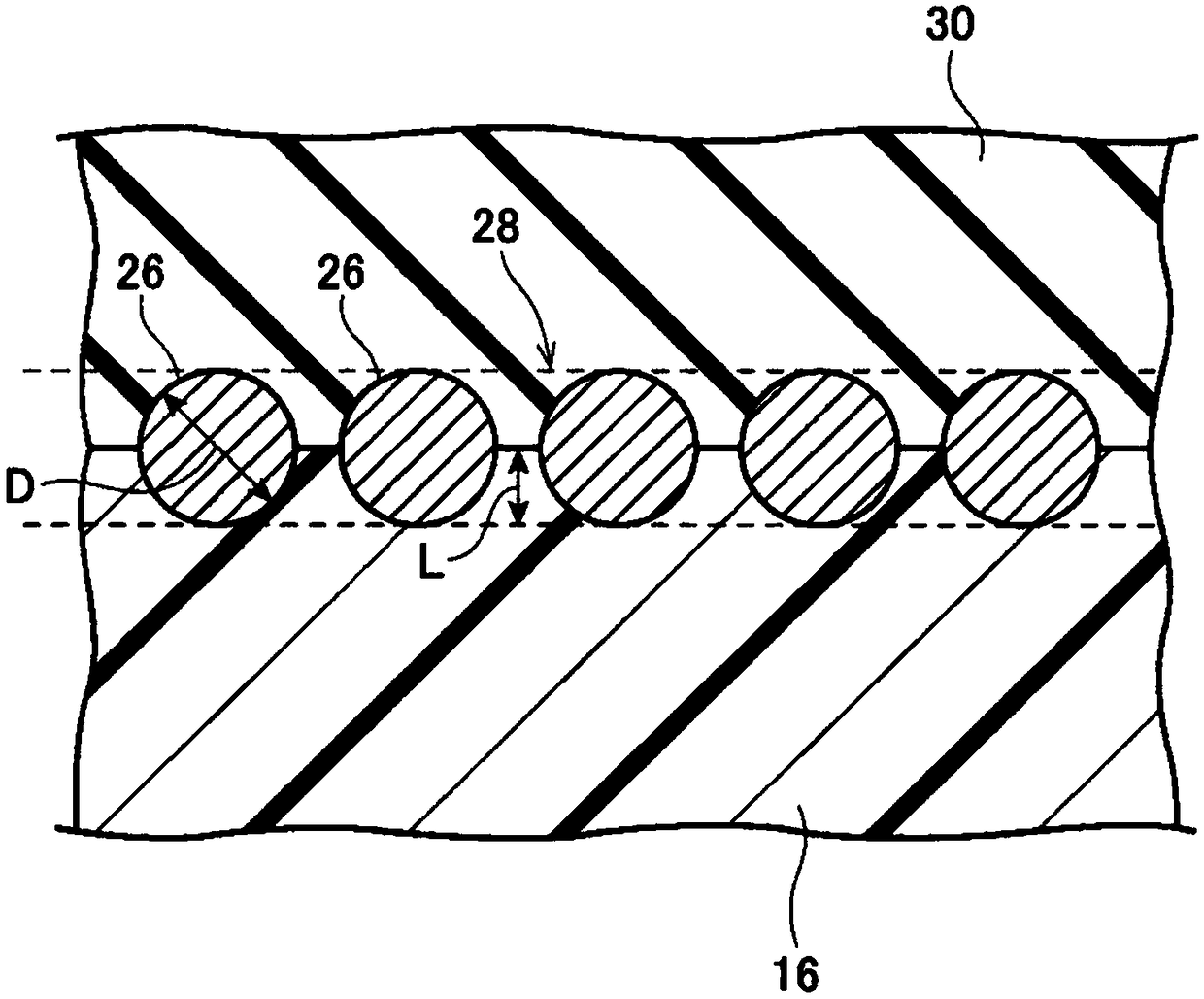

[0157] Such as Figure 1A Shown in , the tire 10 includes the following carcass (tire frame) 17, and the carcass (tire frame) 17 includes: Figure 1B A pair of bead portions 12 each in contact with a bead seat 21 and a rim flange 22 of a rim 20 shown in ; a sidewall portion 14 extending outward in the tire radial direction from each bead portion 12 ; and a sidewall portion A crown portion 16 (peripheral...

no. 2 approach

[0196] Next, a second embodiment of the tire of the present invention is described below with reference to the drawings. Similar to the first embodiment, the tire in this embodiment has substantially the same cross-sectional shape as those of conventional usual rubber-made pneumatic tires. Thus, in the drawings described below, the same reference numerals are assigned to the same constituents as those of the first embodiment, and descriptions thereof may be omitted. Figure 4A is a sectional view of the tire of the second embodiment taken along the tire width direction, and Figure 4B is an enlarged sectional view of a bead portion taken along the tire width direction, showing a state in which a rim is mounted to the tire of the second embodiment. Figure 5 is a sectional view taken along the tire width direction, showing the periphery of the reinforcing layer of the tire of the second embodiment.

[0197] In the tire of the second embodiment, the carcass 17 is formed of the...

Embodiment 1

[0300] Synthesis of Polyamide-Based Thermoplastic Elastomers

[0301] In a 2-liter reaction vessel equipped with a stirrer, a nitrogen inlet, and a condensed water outlet, 77.4 g of sebacic acid (dicarboxylic acid), 10.1 g of 1,4-aminobutane (diamine), 263 g of PPG / PTMG / PPG (polymer forming the soft segment: triblock polyether diamine having amino groups at both ends, trade name: ELASTAMINE (registered trademark) RT-1000, manufactured by HUNTSMAN Corporation), 150 g of pure water, and 0.7 g of sodium hypophosphite, and mix these materials.

[0302] The resulting mixture was subjected to nitrogen substitution, followed by heating to 240°C under sealed pressure. After the container pressure reached 0.5 MPa, the pressure was slowly released, and the mixture was stirred at 240° C. for 5 minutes under a nitrogen stream to obtain a polyamide-based thermoplastic elastomer. The weight-average molecular weights of the polyamide-based thermoplastic elastomers thus obtained are shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com