Spin-casting device and spin-casting centrifugal disk

A centrifugal disc and disc body technology, which is applied in the field of advanced metal material processing and forming, can solve the problems of metal hollow ingots such as collapsed grains and coarseness, and achieve the effect of small grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

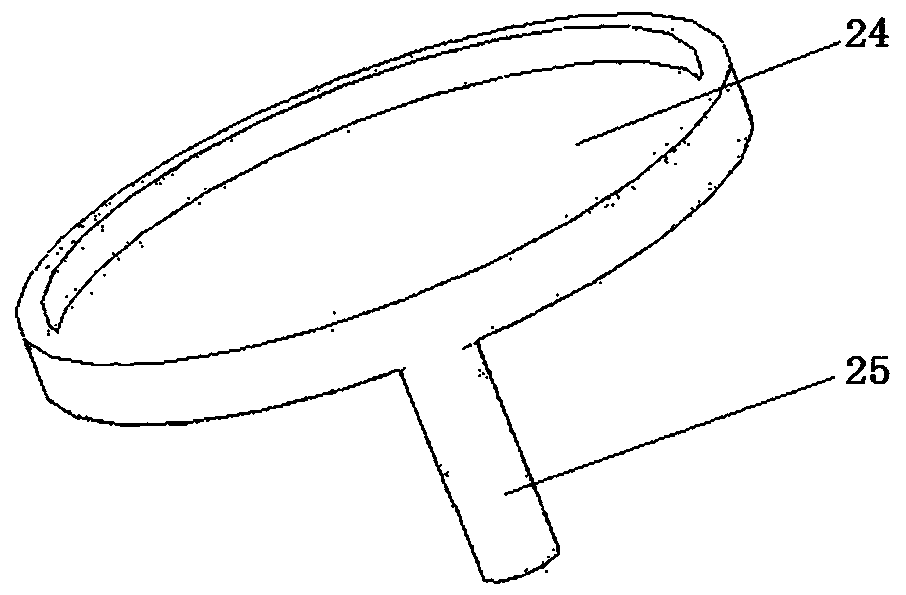

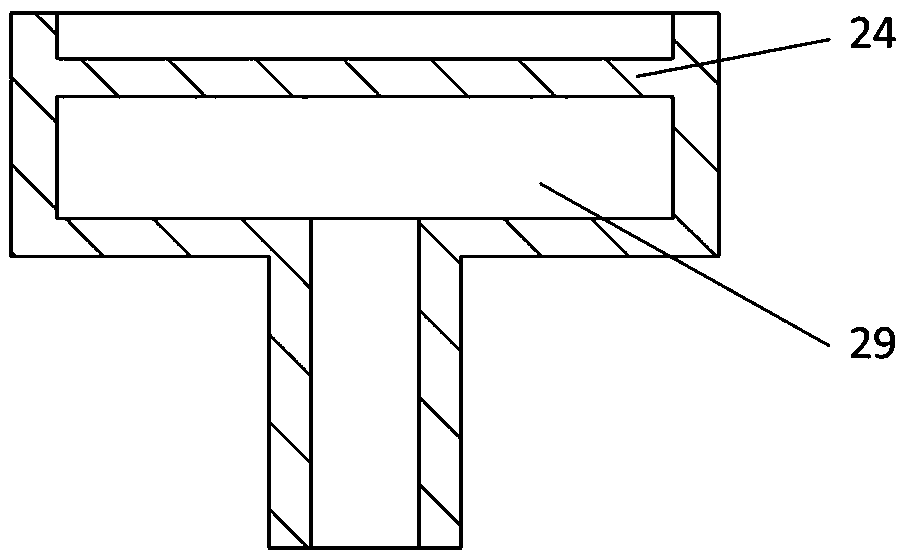

[0025] The throwing casting device of the present invention cools the centrifugal disc and the metal raw material on the centrifugal disc by setting the centrifugal disc cooling medium channel in the centrifugal disc, thereby ensuring that the atomized metal raw material can smoothly form semi-solid small droplets , to ensure that the output of hollow castings has a high quality.

[0026] Embodiments of the throw casting device of the present invention will be further described below in conjunction with the accompanying drawings.

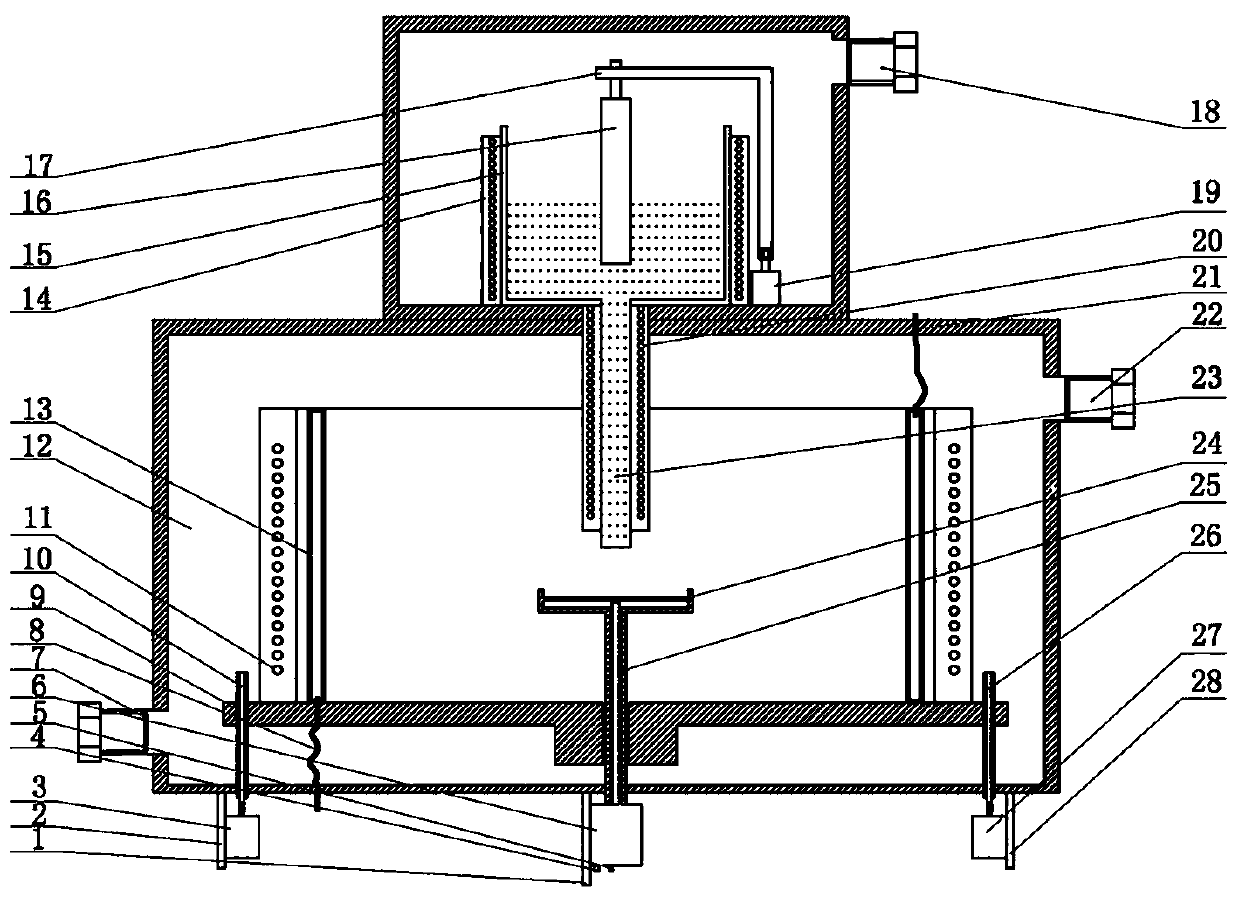

[0027]The embodiment of the throwing casting device of the present invention comprises a fixed frame, and the fixed frame in this embodiment is a closed cabin body, and the cabin body is provided with a vacuum mold forming system, a vacuum melting system and a centrifugal disc high-speed rotating cooling system, The throw casting unit also includes a pressure control system.

[0028] Such as figure 1 As shown, the vacuum mold forming system includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com