Rotating casting method capable of achieving any mold filling force by virtue of centrifugal force and gravity

A rotary casting and centrifugal force technology, applied in the field of material processing, can solve the problems of high processing accuracy, reduced reliability, and high equipment cost, and achieve the effects of convenient adjustment and reduced precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

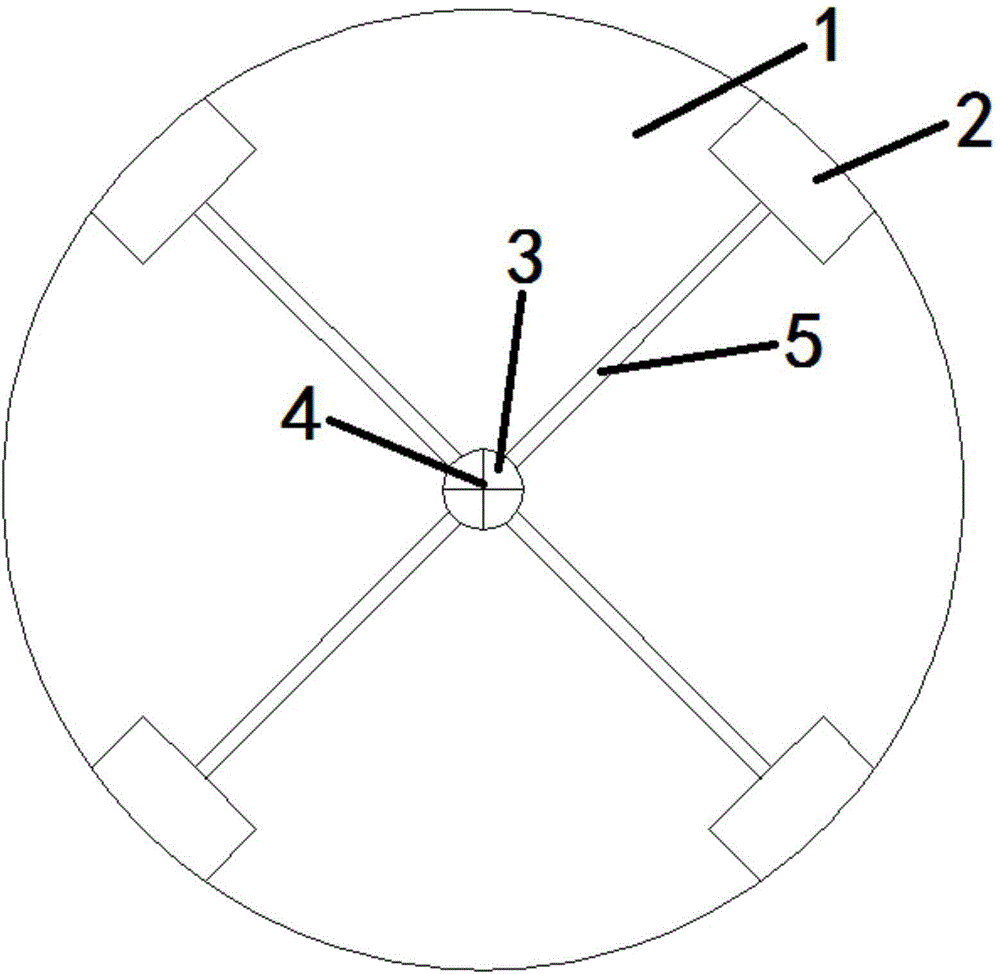

[0022] The diameter of the rotating disk is 2 meters, and there are four mold positions. The gate dividing plate divides the gate into four, such as figure 1 .

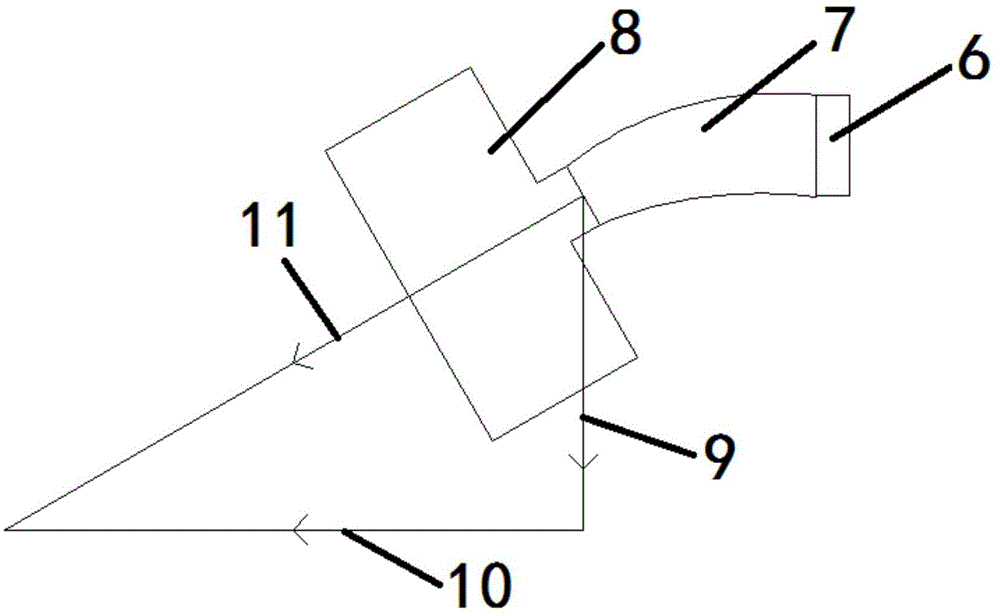

[0023] Adjust the rotation speed of the rotating turntable to make the mold position achieve a centrifugal force of 1.732g. The centrifugal force and gravity cooperate to form a filling force of 2g at an angle of 30° to the horizontal direction. figure 2 .

[0024] The direction of the mold is perpendicular to the direction of the filling force, and the angle between the bottom surface of the mold and the horizontal plane is 60°.

[0025] The mold adopts metal type.

[0026] The applicant declares that the above content is a further detailed description of the present invention in conjunction with specific preferred embodiments, and it cannot be assumed that the specific implementation of the present invention is limited to these descriptions. For those of ordinary skill in the technical fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com