Aluminum alloy hub spinning casting process

An aluminum alloy wheel hub and casting process technology, applied in the field of metal casting, can solve the problems of low product strength, extrusion deformation, easy extrusion and peeling, etc., to reduce product deformation and extrusion defects, reduce product peeling and cracks Defects, the effect of reducing rim defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A spinning casting process for an aluminum alloy wheel, comprising the following steps:

[0021] A. Inject aluminum water into the cavity of the mold, spin out the rim blank after casting the wheel disc, cool down, demould, and carry out spinning casting. During the cooling treatment, the blank is preheated at 410°C, and the front side of the blank after being released from the furnace Cool in water at 45°C for 4 seconds, the rim body does not enter the water, and cool in the air. When the mold temperature is 200°C, the front surface temperature of the blank is 180°C, and the rim blank is 360°C, start spinning; the feed speed is set to 1.0mm / rotation ;

[0022] B. Remove the blank gate;

[0023] C. Heat treatment of the casting blank;

[0024] D. Surface shot blasting of the blank;

[0025] E. Machining the blank;

[0026] F, the surface is painted or electroplated.

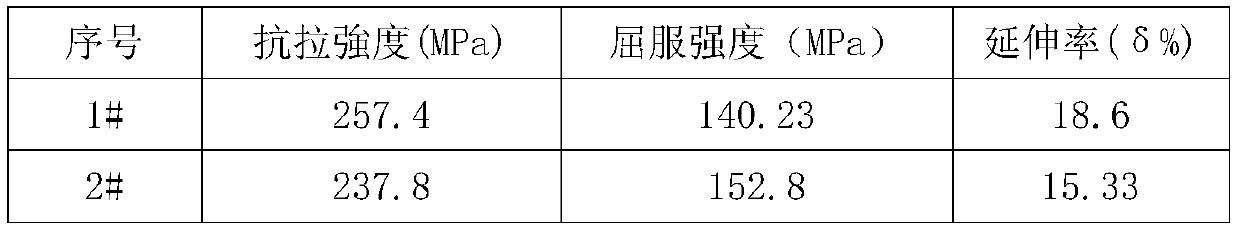

[0027] The physical property data of table 1 gained wheel hub product

[0028]

[0029]

Embodiment 2

[0031] A spinning casting process for an aluminum alloy wheel, comprising the following steps:

[0032] A. Inject aluminum water into the cavity of the mold, spin out the rim blank after casting the wheel disc, cool down, demould, and carry out spinning casting. During the cooling process, the blank is preheated at 430°C, and the front side of the blank after being released from the furnace Cool in 50°C water for 5 seconds, the rim body does not enter the water, and cool in the air. When the mold temperature is 220°C, the front surface temperature of the blank is 200°C, and the rim blank is 380°C, start spinning; the feed speed is set to 1.1mm / rotation ;

[0033] B. Remove the blank gate;

[0034] C. Heat treatment of the casting blank;

[0035] D. Surface shot blasting of the blank;

[0036] E. Machining the blank;

[0037] F, the surface is painted or electroplated.

[0038] The physical property data of table 2 gained wheel hub product

[0039] serial number ...

Embodiment 3

[0041] A spinning casting process for an aluminum alloy wheel, comprising the following steps:

[0042] A. Inject aluminum water into the cavity of the mold, spin out the rim blank after casting the wheel disc, cool down, demould, and carry out spinning casting. During the cooling treatment, the blank is preheated at 450°C, and the front side of the blank after being released from the furnace Cool in 55°C water for 6 seconds, the rim body does not enter the water, and cool in the air. When the mold temperature is 240°C, the front surface temperature of the blank is 220°C, and the rim blank is 400°C, start spinning; the feed speed is set to 1.2mm / rotation ;

[0043] B. Remove the blank gate;

[0044] C. Heat treatment of the casting blank;

[0045] D. Surface shot blasting of the blank;

[0046] E. Machining the blank;

[0047] F, the surface is painted or electroplated.

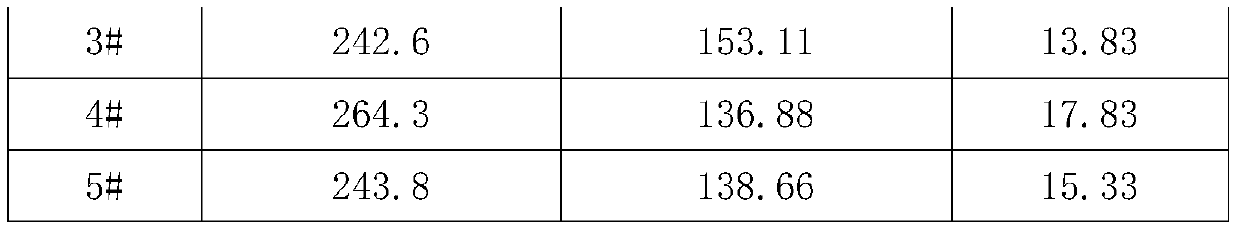

[0048] The physical performance data of the hub product made in table 3

[0049] serial num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com