Automatic online drilling device for rim

A drilling device and automatic technology, which is applied in the direction of positioning device, boring/drilling, drilling/drilling equipment, etc., can solve the problems of drill bit inability to locate, high labor intensity, low efficiency, etc., to avoid frequent breakage, High degree of automation, safe and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

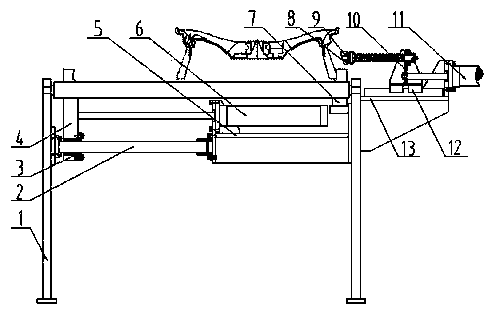

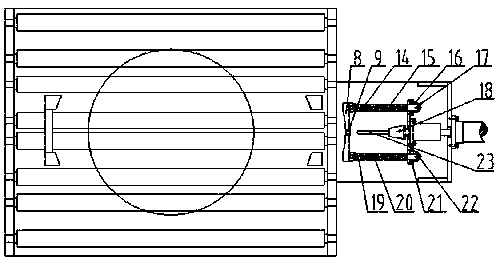

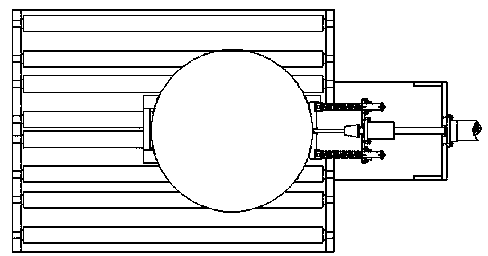

[0013] The details and working conditions of the specific device proposed according to the present invention will be described below in conjunction with the accompanying drawings.

[0014] The device consists of frame 1, guide rod 2, guide sleeve 3, left clamping block 4, lower support plate 5, cylinder 6, right clamping block 7, profiling drilling mold 8, drill sleeve 9, bracket 10, servo motor Cylinder 11, guide rail 12, support platform 13, upper spring 14, upper guide post 15, upper sliding sleeve 16, upper pressing plate 17, drilling power head 18, lower spring 19, lower guiding post 20, lower sliding sleeve 21, lower pressing plate 22 And drill bit 23 is formed. Two guide rods 2 are fixed below the frame 1, and two guide sleeves 3 matched with the guide rods 2 are installed below the two left clamping blocks 4; the cylinder 6 is fixed above the lower support plate 5, and the output rod of the cylinder 6 is connected to the two The middle connecting parts of the two left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com