Structure-improved tire ring belt machine suction plate

A technology of tires and endless belts, which is applied to tires, other household appliances, household appliances, etc., can solve problems such as waste of time, increased processing costs, rupture and damage, etc., to improve processing efficiency, prolong service life, and reduce stress concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

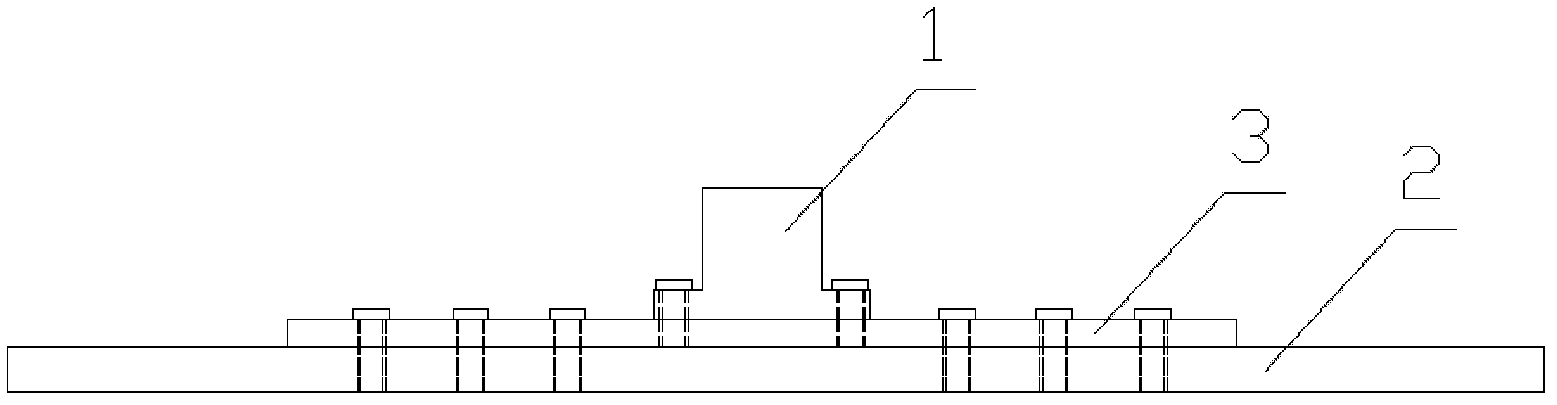

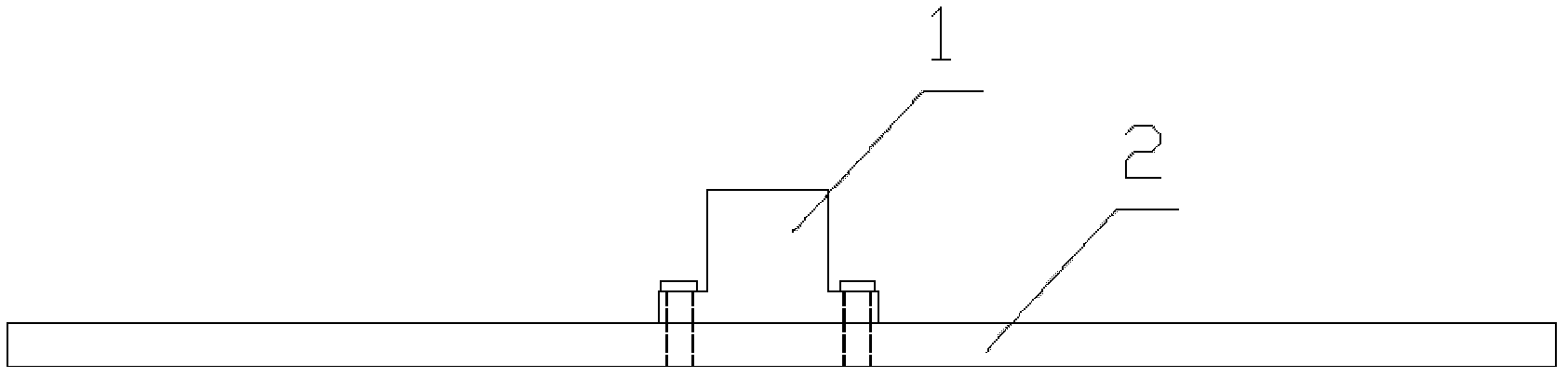

[0009] Embodiment: A suction plate of a tire endless belt machine with improved structure, including a bracket 1, a belt fixing plate 2, and a strip-shaped reinforcing plate 3 with a length longer than the length of the bracket 1, and the reinforcing plate 3 is fixed with the belt fixing plate 2 connection, the bracket 1 is fixed on the side of the reinforcing plate 3 facing away from the belt fixing plate 2, the tension of the bracket 1 directly acts on the reinforcing plate 3, and the reinforcing plate 3 then acts on the belt fixing plate 2. Since the reinforcing plate 3 is longer, the The large pulling force is decomposed into several small pulling forces, which reduces the stress concentration on the belt reinforcement plate 3 and effectively avoids frequent fractures of the belt fixing plate 2 due to stress concentration.

[0010] Between the bracket 1 and the reinforcing plate 3 and between the reinforcing plate 3 and the belt fixing plate 2, screws are used to connect, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com