Systems and methods for a thermistor furnace

a technology of thermistor furnace and system, which is applied in the direction of casting parameters measurement/indication devices, manufacturing tools,foundry moulding apparatus, etc., can solve the problems of inability to use graphite molds and inability to produce highly detailed cast products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

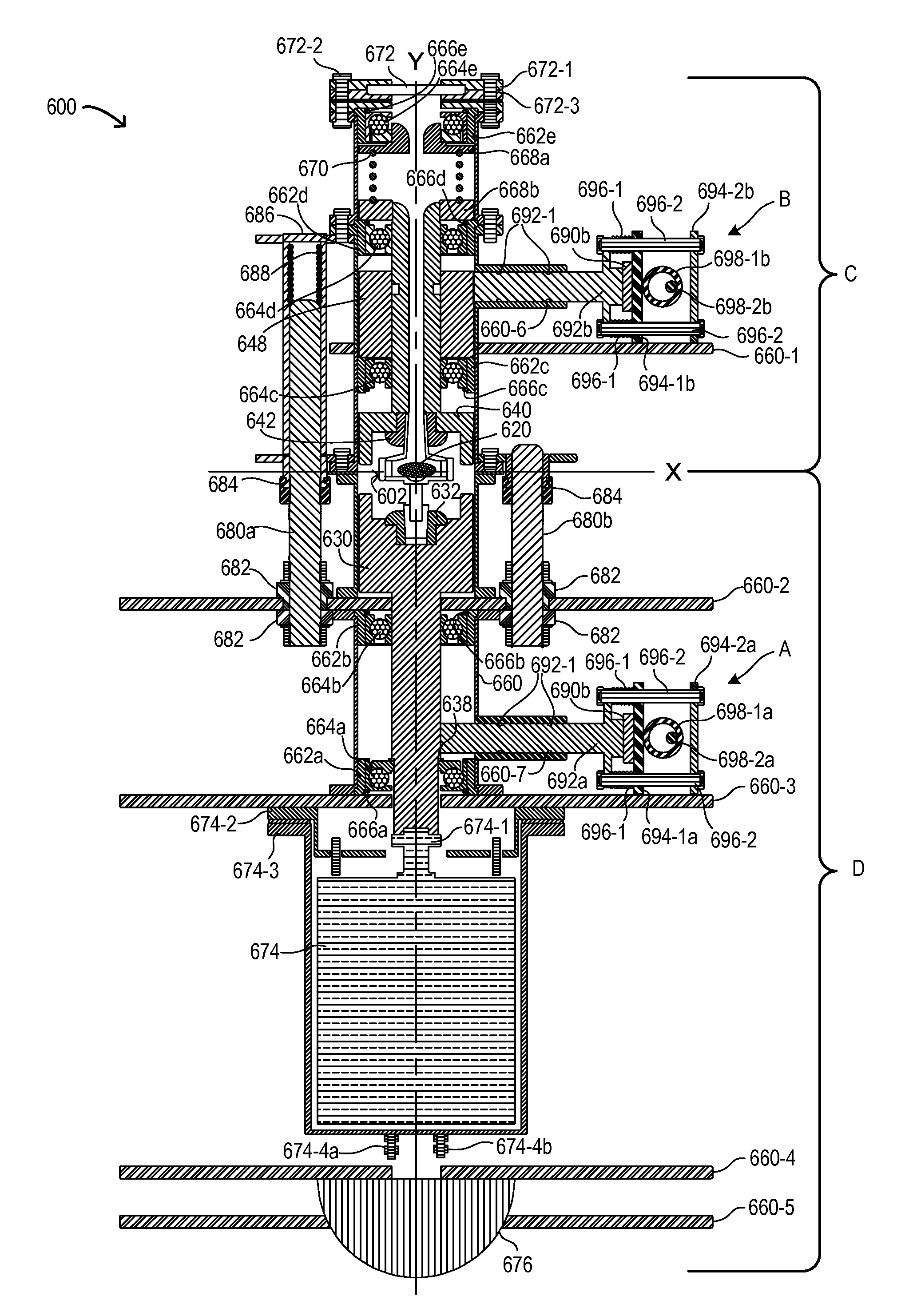

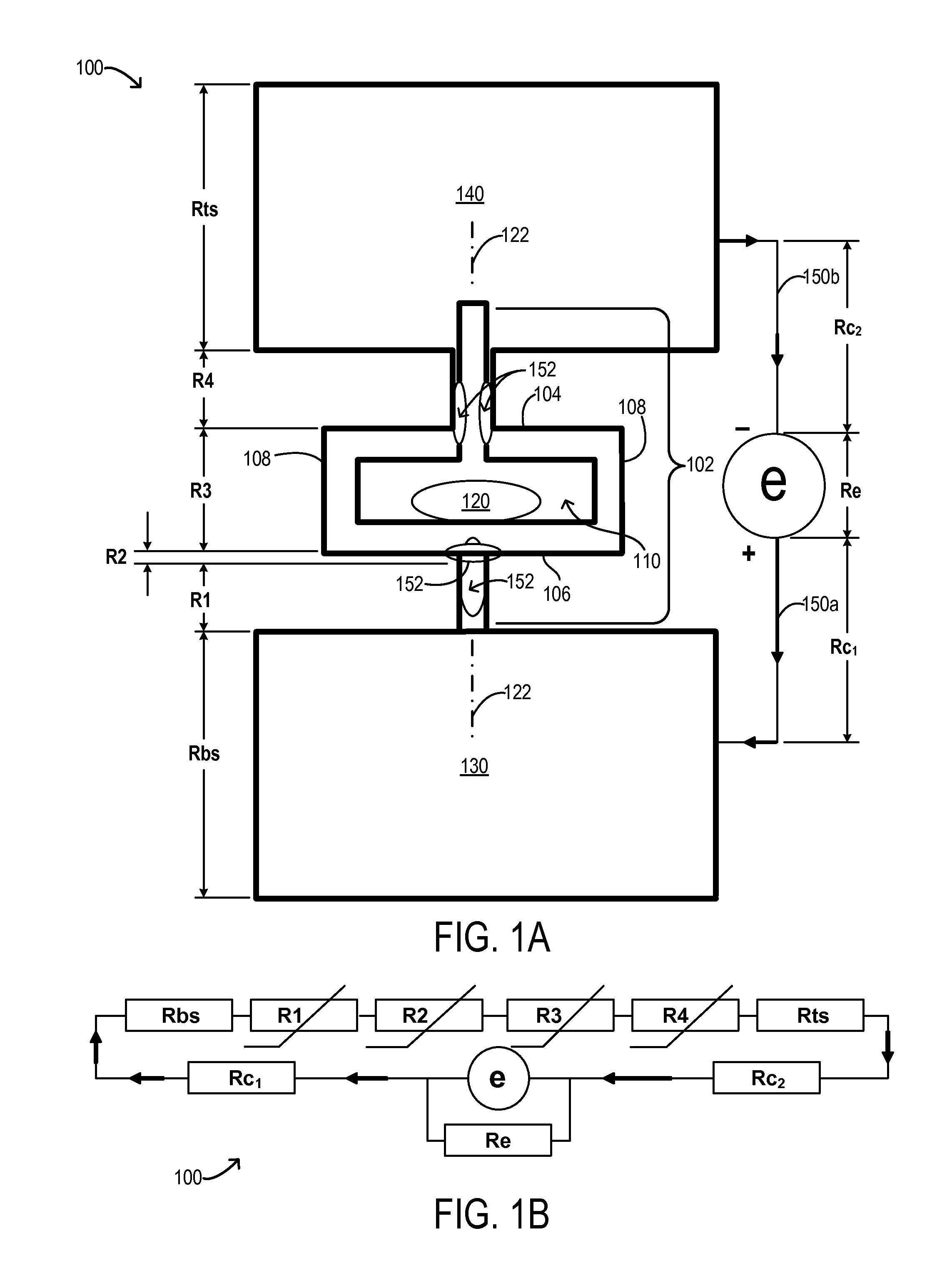

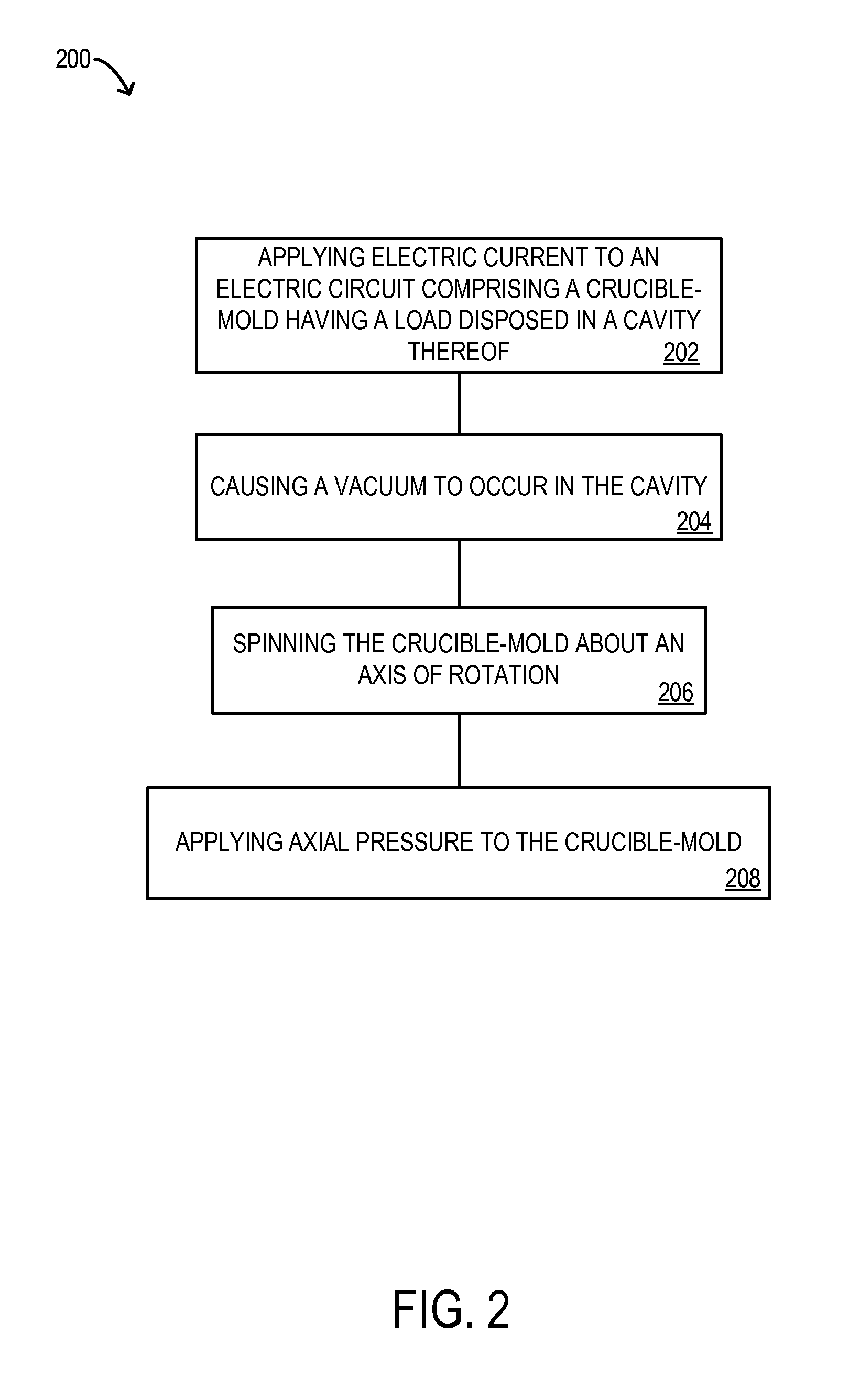

[0017]Embodiments provided herein are descriptive of systems, apparatus, methods, and articles of manufacture that provide for a thermistor furnace, such as for melting, casting, and / or smelting metals (e.g., precious metals and / or other metals, such as titanium, or other materials, such as thermoset plastic). In some embodiments, the thermistor furnace may comprise a vacuum spin casting apparatus capable of utilizing various types and configurations of molds. Casting molds comprised of graphite, for example, such as fine-grained, high-density, high-strength, isotropic graphite, may be utilized to produce spin casting products with improved surfaces, improved structural integrity, lack of seams, and improved mechanical properties. Existing furnaces and / or melting, casting, or smelting apparatus, such as typical inductive heating furnaces, suffer from many deficiencies. In accordance with embodiments described herein, Applicants disclose a thermistor furnace (e.g., configured for vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

| Vacuum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com