Method for enhancing work hardening capacity of beta-type amorphous alloy endogenous composite material

A composite material and amorphous alloy technology is applied in the field of improving the work hardening ability of β-type amorphous alloy endogenous composite materials, which can solve the problems of weak work hardening ability and restricting the practical application of structural materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

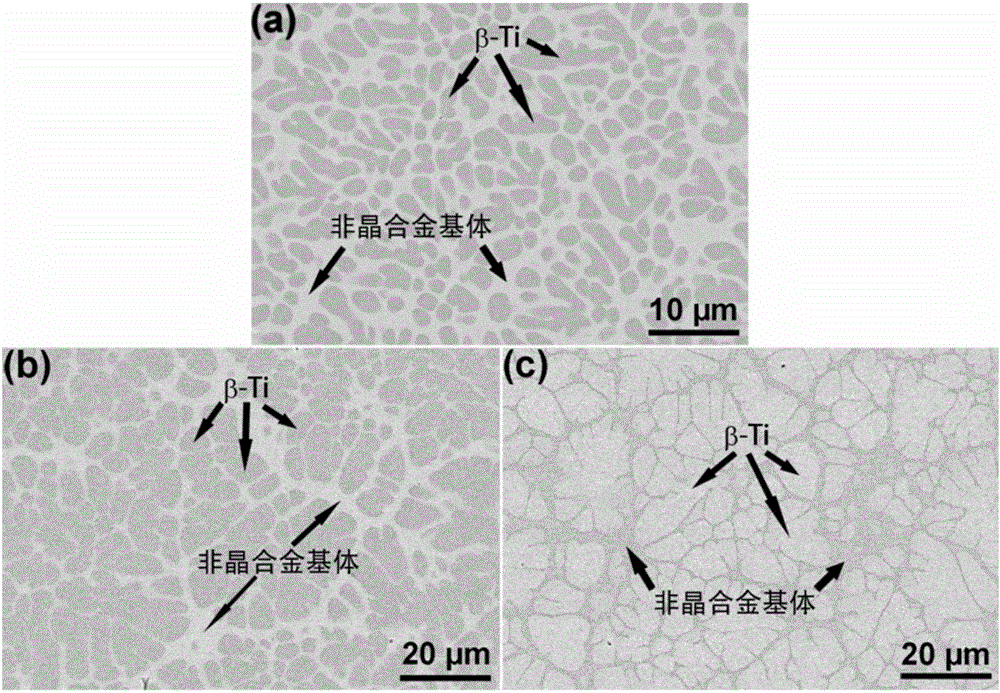

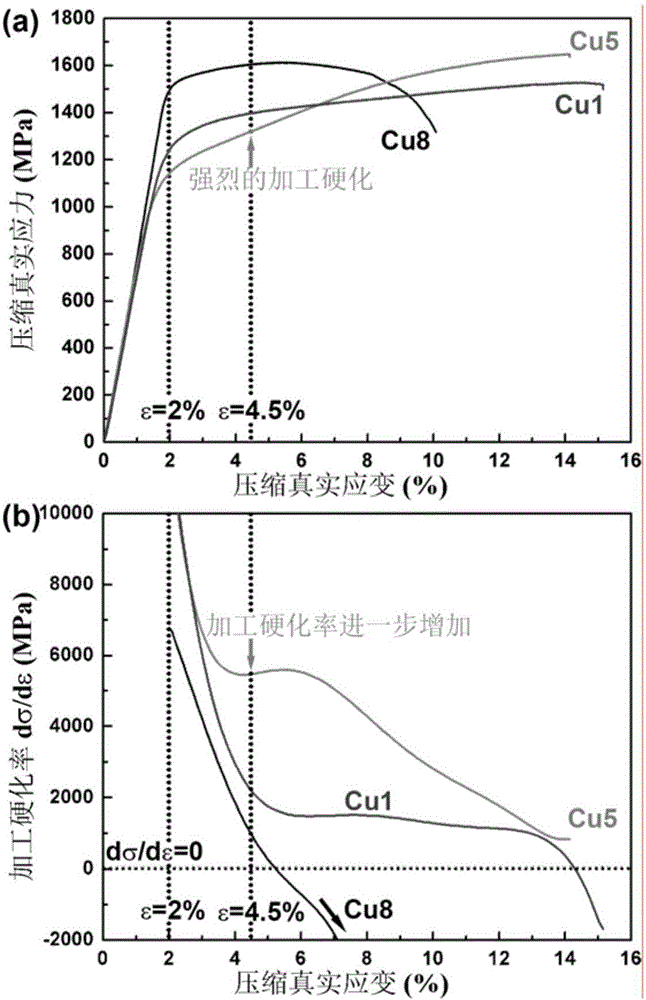

[0047] For the nominal composition (Ti 50.5 Zr 35.3 Fe 2.8 be 11.4 ) 100-x Cu x (atomic percent) alloy, x is taken as 8 or 5, and is defined as Cu8 or Cu5 alloy, respectively. The alloy with the nominal composition of Cu8 or Cu5 was cast into a round rod with a diameter of 6 mm through a Cu mold. The microstructures of Cu8 and Cu5 alloys are both amorphous alloy endogenous composite materials: the β phase is distributed in the continuous amorphous matrix, see figure 1 (a) and (b). The particle diameters and volume fractions of the beta phase in both samples are listed in Table 1 below. The average particle diameter and volume fraction of the β phase increased with decreasing Cu content. The chemical composition of the β-phase in the two samples was characterized by the electron spectrum of the scanning electron microscope, which is listed in Table 1. With the decrease of the Cu content in the nominal composition of the alloy, the molybdenum equivalent ([Mo] eq ) was ...

Embodiment 2

[0054] For the nominal composition (Ti 50.5 Zr 35.3 Fe 2.8 be 11.4 ) 100-x Cu x (atomic percent) alloy, x is taken as 1, and defined as Cu1 alloy. An alloy with a nominal composition of Cu1 was cast into a round rod with a diameter of 6 mm through a Cu mold. The microstructure of Cu1 alloy is also an amorphous alloy endogenous composite material, see figure 1 (c). Comparing the Cu8 and Cu5 alloys in Example 1, with the further reduction of the Cu content, the average particle diameter and volume fraction of the β phase in the Cu1 alloy further increased, and the molybdenum equivalent of the β phase stable elements (Cu, Fe) in the β phase further decreased , see Table 1.

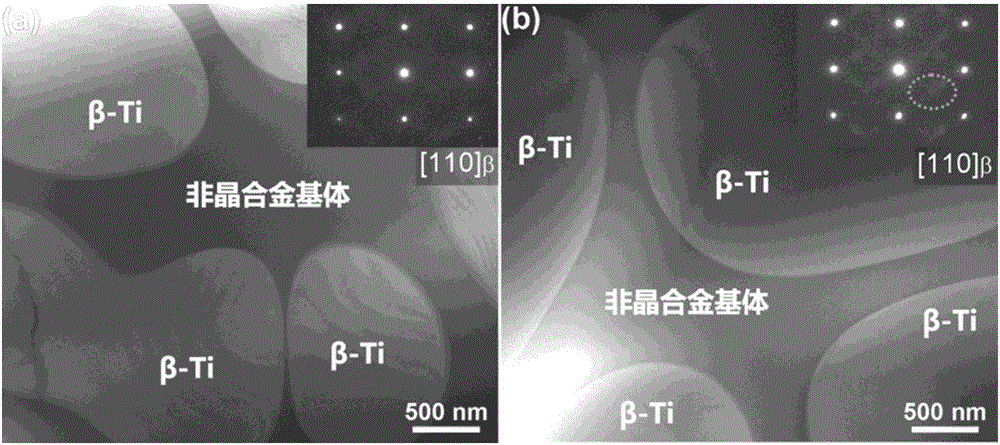

[0055] Unlike the β phase in Cu8 and Cu5 alloys, a large number of dispersed ω phases are generated inside the β phase in Cu1 alloy, see Figure 5 (a) and (b). This is due to the very low structural stability of the β phase in the Cu1 alloy, resulting in the collapse of the body-centered cubic latti...

Embodiment 3

[0057] For the nominal composition (Ti 50.5 Zr 35.3 co 2.8 be 11.4 ) 100-x Cu x (atomic percent) alloy, x is taken as 8 or 5, and these two alloys are defined as CC-Cu8 and CC-Cu5 respectively.

[0058]The alloys with the nominal composition of CC-Cu8 and CC-Cu5 were prepared into round rods with a diameter of 6 mm through Cu mold casting. These two alloy rods are both amorphous alloy endogenous composite materials. Cut 3 x 3 x 6mm from a 6mm round bar 3 The compression test was carried out on compression specimens of different sizes. The true stress-strain curves of the two alloys are Figure 6 shown. The CC-Cu8 alloy yielded at 1220MPa, and the stress continued to increase to 1500MPa at fracture (true strain of 8%) after yielding. Its work hardening ability is small. The CC-Cu5 alloy yielded at 1050MPa, and its true stress increased significantly after yielding to 1650MPa where the true strain was 10%, then the stress decreased slightly, and failure occurred when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com