Medium-chromium ferrite stainless steel for automobile with high formability and acidic corrosion resistance as well as manufacturing method thereof

A technology of formability and acid resistance, applied in the direction of manufacturing tools, metal rolling, temperature control, etc., can solve the problems of not meeting the requirements of use, increasing the production cost and management cost of materials, and not reaching the life guarantee period, so as to improve the quality of materials Effects of texture, improvement of overall performance, and improvement of formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below by embodiment.

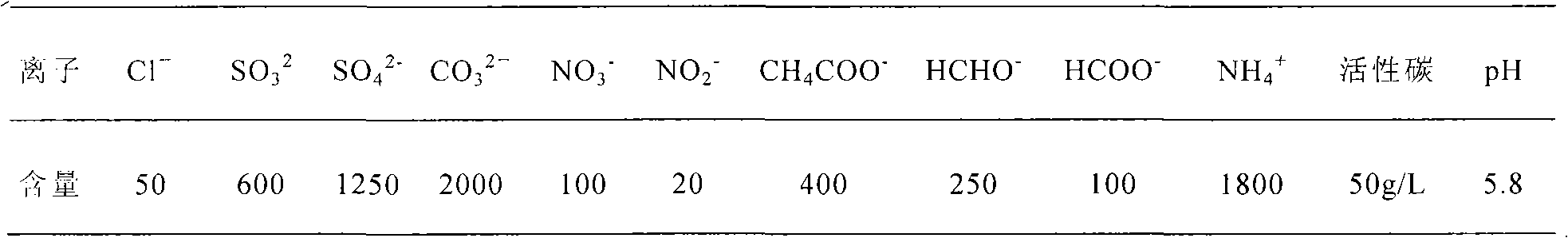

[0054] Add materials according to the composition in Table 3 (except Ti), through the three-step method of electric furnace steelmaking, AOD decarburization, and VOD deoxidation, and add Ti after the end of VOD. After the comprehensive composition meets the design requirements, the satisfactory composition can be obtained. Liquid steel required. By controlling the casting speed of the continuous casting process, 0.9-1.1m / min, strengthening electromagnetic stirring, and current 1000-1600 amperes, the molten steel is continuously cast to obtain a continuous casting slab, and the proportion of equiaxed crystals in the continuous casting slab is not less than 50%. The surface of the continuous casting slab is ground, and after the grinding, it is sent to the heating furnace for heating and holding for a certain period of time for hot rolling. Hot rolling first removes the surface scale and performs roug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com