Multi-Purpose Well Servicing Apparatus

a multi-purpose, well-maintained technology, applied in mechanical equipment, wellbore/well accessories, drilling pipes, etc., can solve the problems of high cost, difficult to change scraper blades/brushes, and limitations of known prior art tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

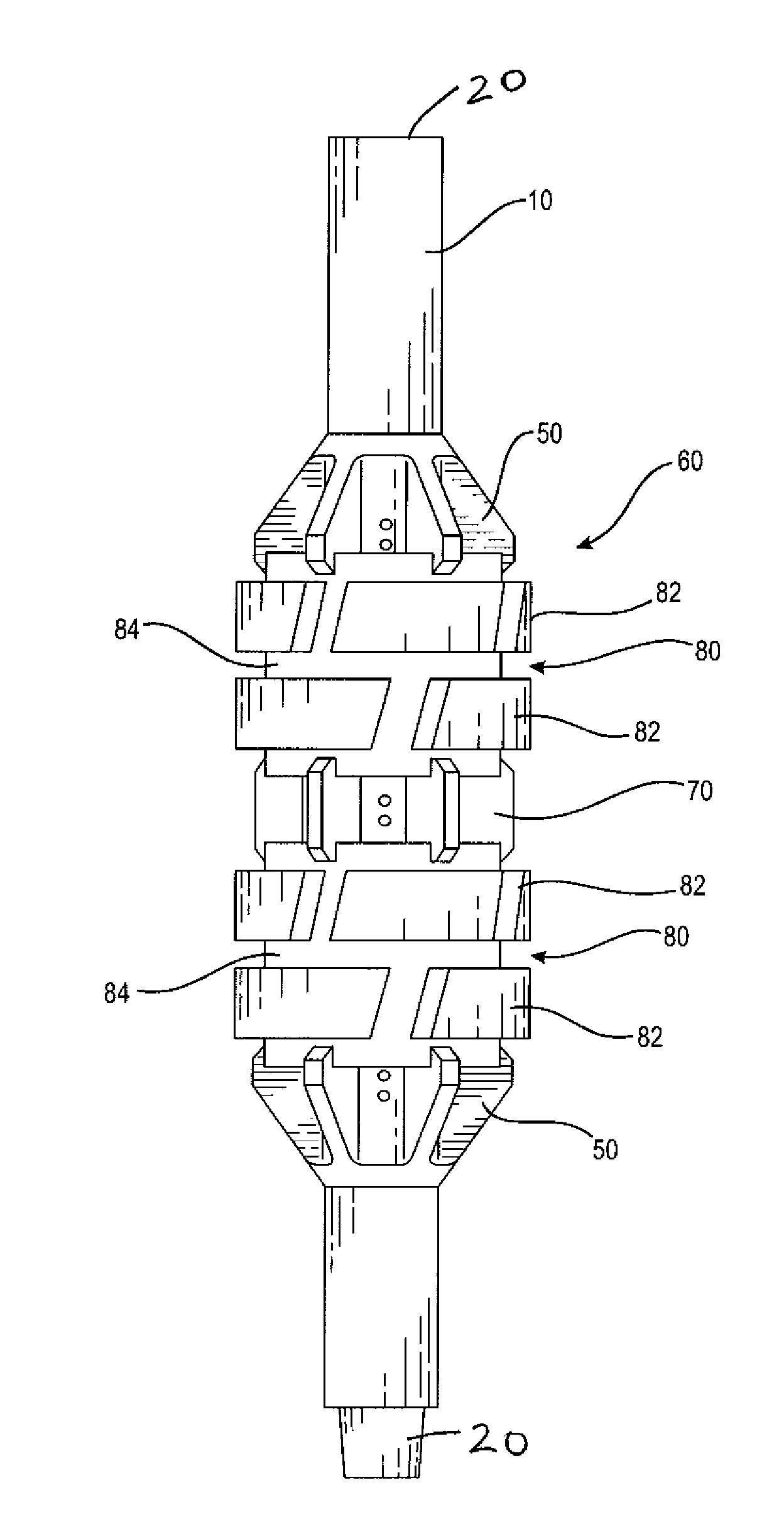

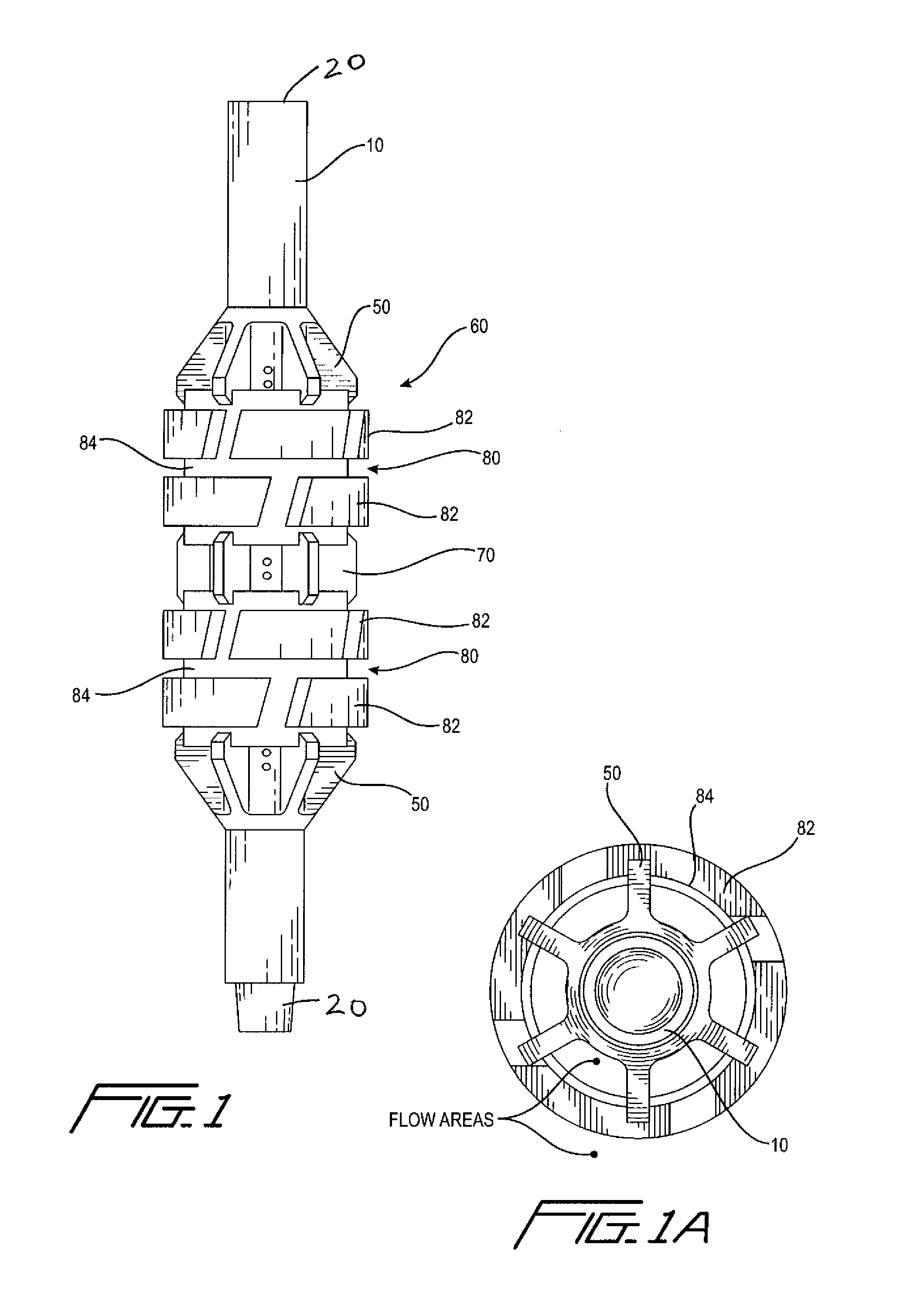

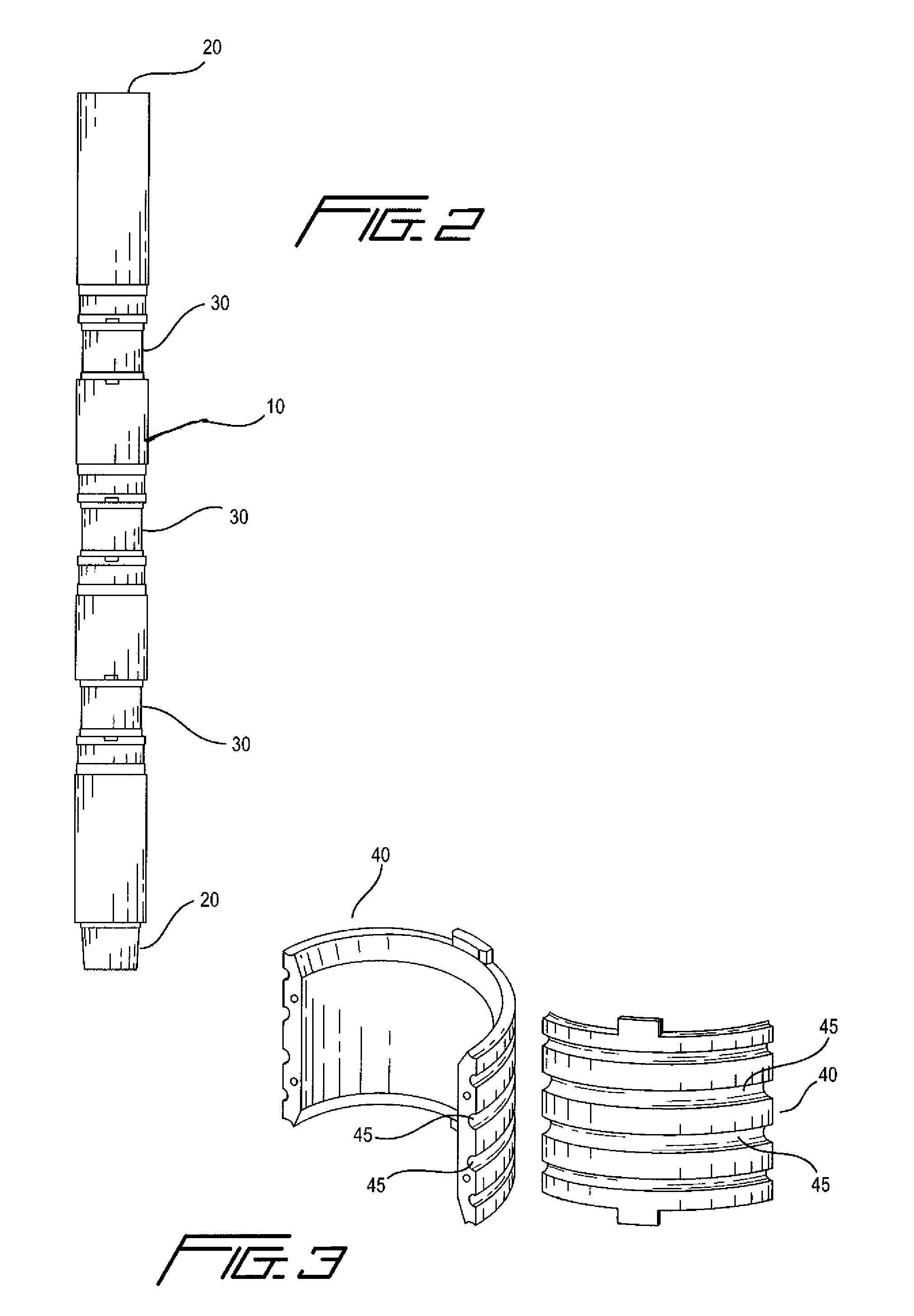

[0022]Various embodiments of the present invention comprise enhanced and improved downhole tool assemblies, for cleaning the internal wall of tubulars (casing, risers, etc.) and the collection of the material being cleaned. Generally, a downhole tool comprising the present invention is connected to a string of drill pipe, work string, tubing, or the like, referred to collectively as a “drill string,” to be run into a wellbore tubular, and used in the servicing of oil and gas wells. For this application, the term “wellbore” includes without limitation any downhole tubular, whether a casing string, a riser associated with a floating drilling rig or any other type rig, or any other tubular member. In an exemplary embodiment, the apparatus of the present invention comprises two primary elements:[0023]1) a central mandrel, typically connected by a threaded connection to a drill string, comprising an outer diameter profile (such as under-cut profiles or other outer diameter variations) wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com