Method for improving damage tolerance performance of Al-Cu-Mg alloy

An al-cu-mg, alloy technology is applied in the field of improving the damage tolerance performance of Al-Cu-Mg alloy and improving the stress field intensity factor of Al-Cu-Mg alloy during fatigue fracture, which can solve the problem of unseen aluminum alloy sheets. Damage tolerance performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

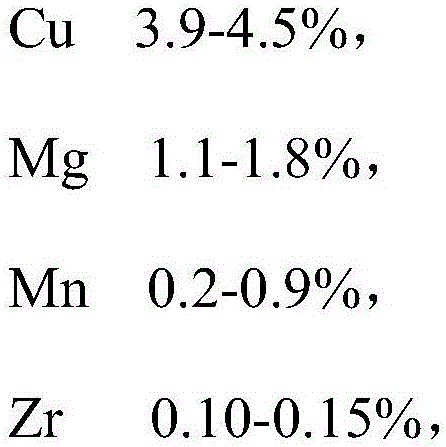

Embodiment 1

[0031] The composition of the alloy is Cu3.9%, Mg1.1%, Mn0.2%, Fe0.08%, Si0.04%, Zn0.08%, Ti0.06%, and the balance is Al. Solution quenching for 10 minutes, followed by cold rolling pre-deformation treatment with a deformation amount of 6%, and finally natural aging for at least 96 hours. The tensile properties of the obtained plate are: tensile strength is 443.29MPa, yield strength is 371.21MPa, and elongation is 23.39%. The damage tolerance performance is: ΔK=38.75MPam corresponding to fatigue fracture 1 / 2 ;Corresponding fatigue crack growth rate da / dN=1.55×10 -3 mm / cycle.

Embodiment 2

[0033] The composition of the alloy is Cu4.2%, Mg1.4%, Mn0.5%, Fe0.09%, Si0.03%, Zn0.06%, Ti0.05%, and the balance is Al. Solution quenching for 30 minutes, followed by cold rolling pre-deformation treatment with a deformation amount of 7.9%, and finally natural aging for at least 96 hours. The tensile properties of the obtained plate are: tensile strength is 445.24MPa, yield strength is 376.11MPa, and elongation is 22.05%. The damage tolerance performance is: ΔK=38.26MPam corresponding to fatigue fracture 1 / 2 ;Corresponding fatigue crack growth rate da / dN=1.69×10 -3 mm / cycle.

Embodiment 3

[0035] The composition of the alloy is Cu4.5%, Mg1.8%, Mn0.9%, Fe0.05%, Si0.05%, Zn0.06%, Ti0.07%, and the balance is Al. Solution quenching for 60 minutes, followed by cold rolling pre-deformation treatment with a deformation amount of 12.1%, and finally natural aging for at least 96 hours. The tensile properties of the obtained plate are: the tensile strength is 449.35MPa, the yield strength is 382.52MPa, and the elongation is 19.22%. The damage tolerance performance is: ΔK=39.47MPam corresponding to fatigue fracture 1 / 2 ;Corresponding fatigue crack growth rate da / dN=8.60×10 -3 mm / cycle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com