Thermal processing process for improving damage tolerance performance of titanium alloy forge piece

A damage tolerance, titanium alloy technology, applied in the field of optimizing the comprehensive properties of titanium alloys, can solve problems such as reducing room temperature tensile plasticity or fatigue strength, achieve low fatigue crack growth rate, improve greatly reduce room temperature tensile, high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

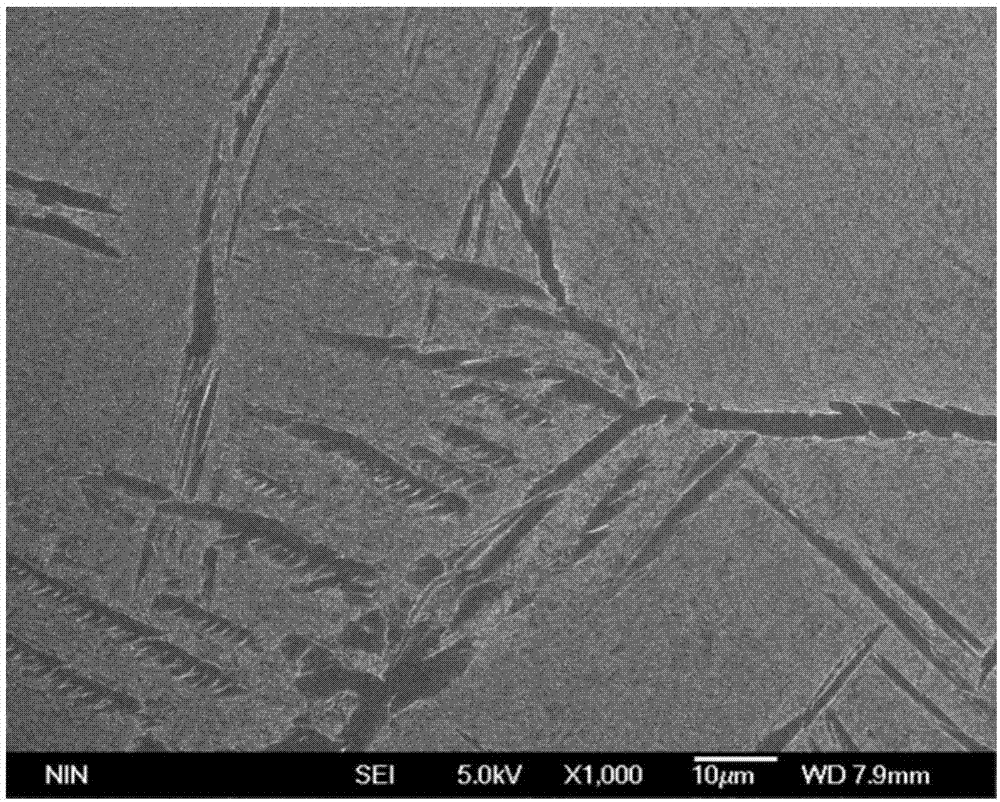

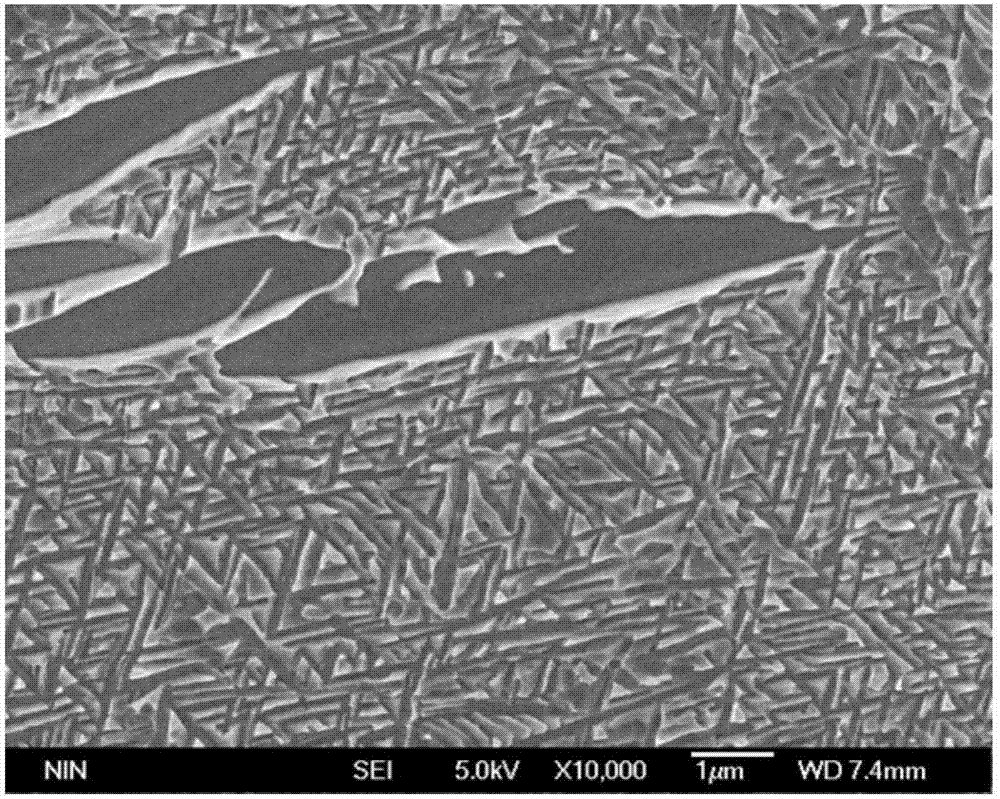

[0023] In this embodiment, the heat treatment process for improving the damage tolerance performance of titanium alloy forgings includes the following steps:

[0024] Step 1, performing solution treatment on the titanium alloy forging obtained by forging below the phase transition temperature; the temperature T of the solution treatment 1 It is 30°C above the phase transition point temperature T of titanium alloy forgings (that is, T 1 =T+30°C), holding time t is 110min, t=(d×0.6+20)min; the titanium alloy forging is a Ti-5553 titanium alloy forging whose phase transition temperature is 850°C, and its cross-sectional diameter d 150mm;

[0025] Step 2. Cool the titanium alloy forging after solution treatment in step 1 to 60°C below its phase transition temperature T (ie T-60°C=790°C) at a cooling rate of 0.5°C / min, and then air-cool to room temperature;

[0026] Step 3: Perform aging treatment on the titanium alloy forging after air-cooling in step 2, and then air-cool to ro...

Embodiment 2

[0031] In this embodiment, the heat treatment process for improving the damage tolerance performance of titanium alloy forgings includes the following steps:

[0032] Step 1, performing solution treatment on the titanium alloy forging obtained by forging below the phase transition temperature; the temperature T of the solution treatment 1 It is 50°C above the phase transition point temperature T of titanium alloy forgings (that is, T 1 =T+50°C), the holding time t is 150min, t=(d×0.6+30)min; the titanium alloy forging is a TB6 titanium alloy forging with a phase transition temperature of 810°C, and its cross-sectional diameter is 200mm;

[0033] Step 2. Cool the titanium alloy forging after the solution treatment in step 1 to 70°C below its transformation point temperature T (ie T-70°C=740°C) at a cooling rate of 0.8°C / min, and then air-cool to room temperature;

[0034] Step 3: Perform aging treatment on the air-cooled titanium alloy forging in step 2, and then air-cool to ...

Embodiment 3

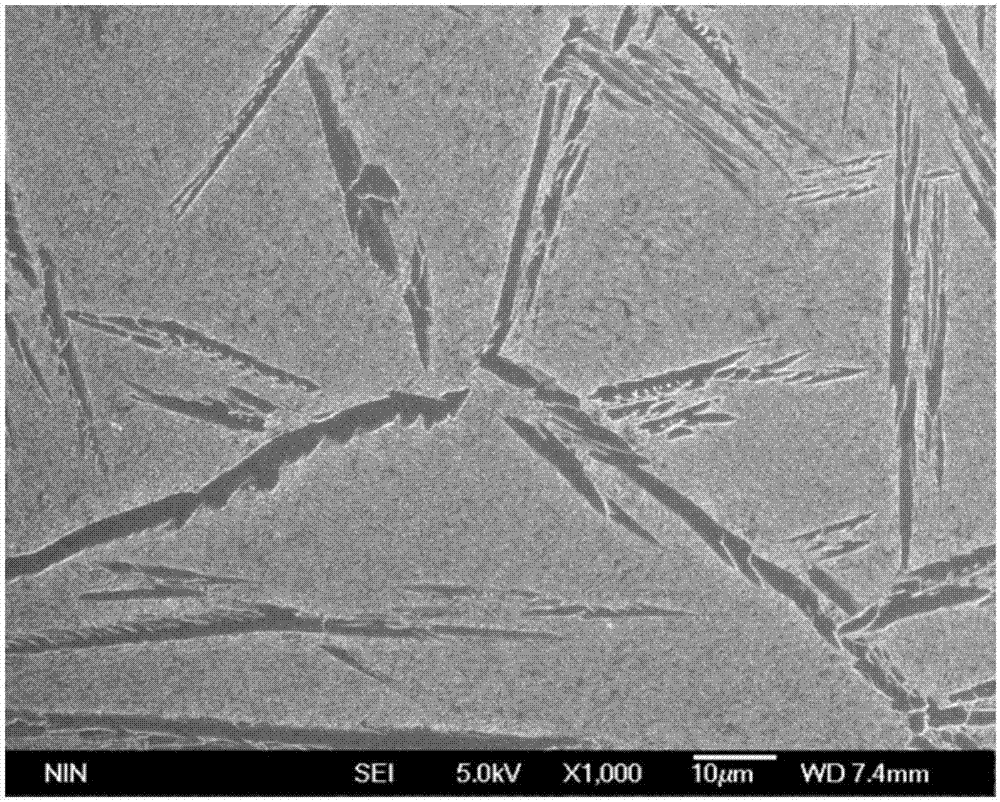

[0039] In this embodiment, the heat treatment process for improving the damage tolerance performance of titanium alloy forgings includes the following steps:

[0040] Step 1, performing solution treatment on the titanium alloy forging obtained by forging below the phase transition temperature; the temperature T of the solution treatment 1 It is 45°C above the phase transition point temperature T of titanium alloy forgings (that is, T 1=T+45°C), holding time t is 158min, t=(d×0.6+26)min; the titanium alloy forging is a Ti-1300 titanium alloy forging whose phase transition temperature is 830°C, and its cross-sectional diameter is 220mm;

[0041] Step 2. Cool the titanium alloy forging after solution treatment in step 1 to 60°C below its phase transition temperature T (ie T-60°C=770°C) at a cooling rate of 1°C / min, and then air-cool to room temperature;

[0042] Step 3: Perform aging treatment on the air-cooled titanium alloy forging in step 2, and then air-cool to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com