A three-dimensional fiber skeleton toughened cermet and its preparation method

A fiber skeleton and cermet technology, which is applied in the field of cermet materials, can solve the problems of high brittle fracture failure of cermets, achieve good damage tolerance performance, high-efficiency fiber toughening, and improve toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

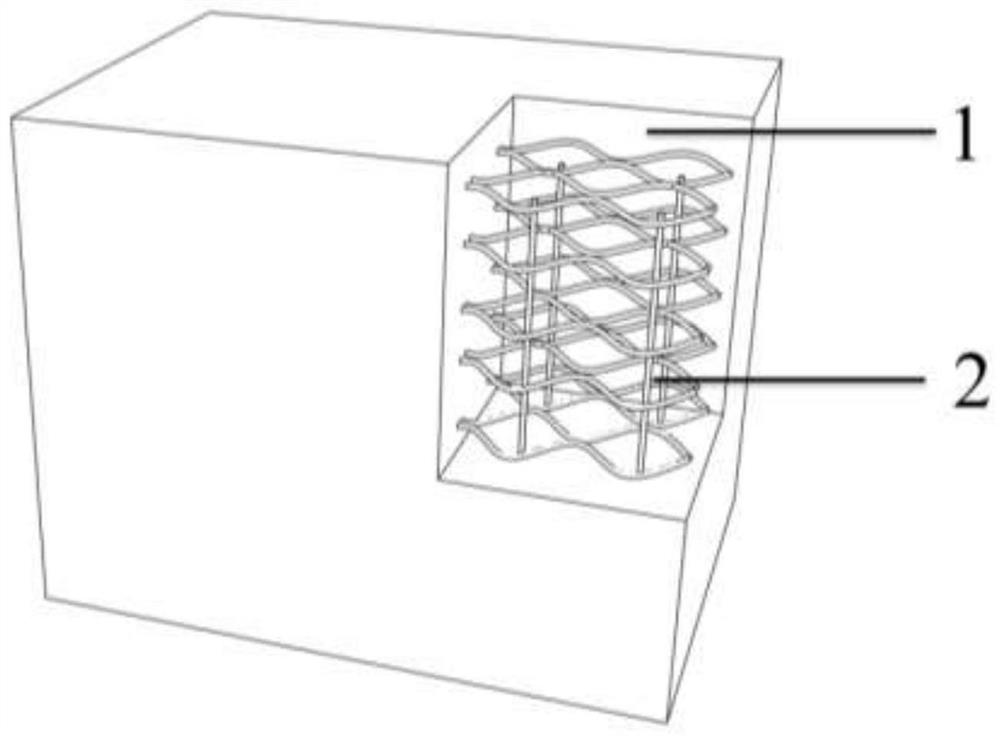

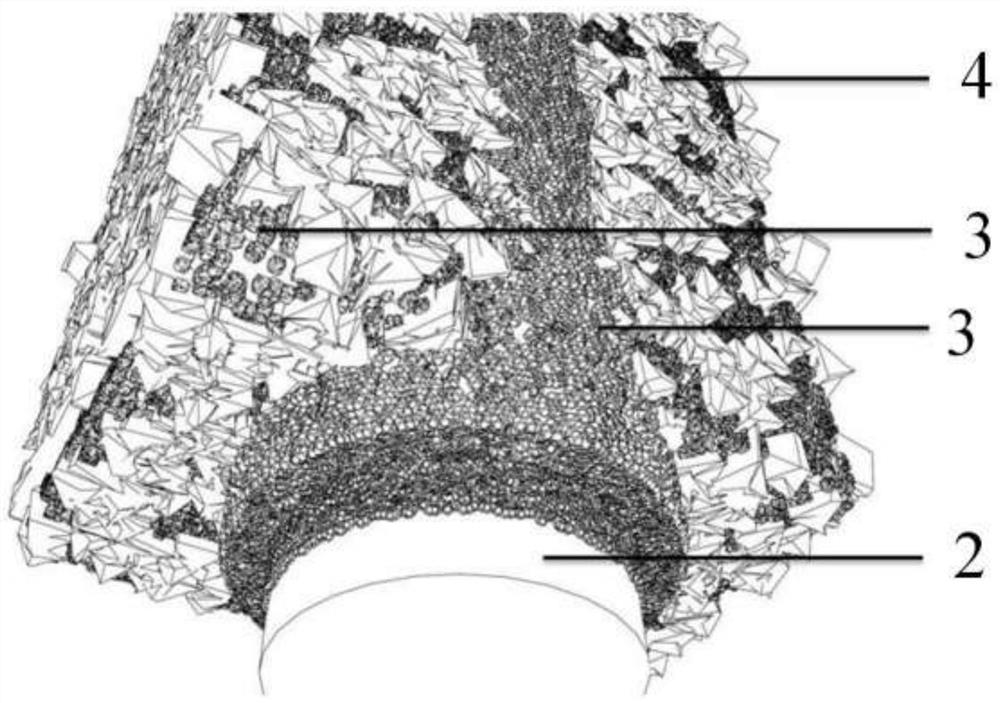

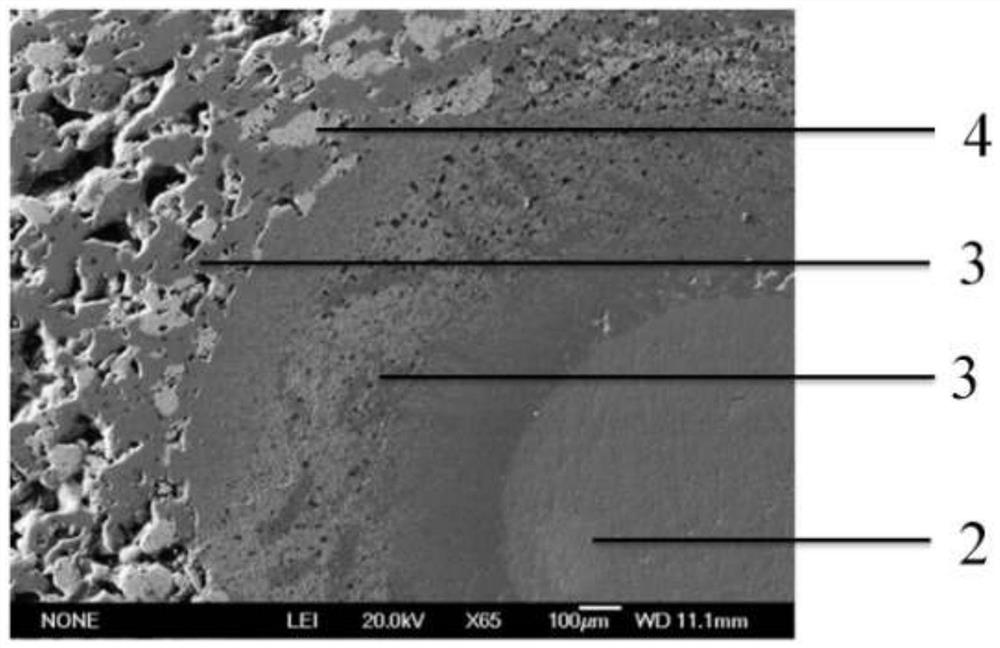

[0034] A preparation method of a three-dimensional fiber skeleton toughened cermet of the present invention comprises the following steps:

[0035] Step 1, weigh the following components according to the mass percentage, WC, WN, Cr with a particle size of 5-20 μm 2 C 3, CrN, TiC, TiN, SiC, SiN powder or one or more of them, or multi-component solid solution composed of W, Cr, Ti, Si, C and N 70%-85%, Nb powder with a particle size of 5μm-10μm Or 5-15% of Ta powder, 5-15% of cast iron powder (HT300) with a particle size of 1μm-5μm; the sum of the volume percentages of the above components is 100%;

[0036] Step 2: using a ball mill to mix the powder weighed in step 1 evenly to form a mixed powder;

[0037] Step 3: adding a small amount of plasticizer to the mixed powder, and then putting it into a mixer for plasticizing treatment and granulation to form a mixed material; wherein, the mass percentage of the plasticizer in the mixed powder is 0.6-0.9 wt%.

[0038] Step 4: Pref...

Embodiment 1

[0042] A preparation method of a three-dimensional fiber skeleton toughened cermet of the present invention comprises the following steps:

[0043] Step 1: Weigh 70% of WC powder with an average particle size of 20 μm, 15% of Nb powder with an average particle size of 10 μm, and 15% of cast iron powder (HT300) with a particle size of 5 μm according to mass percentage, and the sum of the volume percentages of the above components 100%; the purity of the above powders is greater than 99.5%;

[0044] Step 2: using a ball mill to mix the powder weighed in step 1 evenly to form a mixed powder;

[0045] Step 3: Add a small amount of plasticizer to the mixed powder, and then put it into a mixer for plasticization and granulation to form a mixed material; wherein, the plasticizer is paraffin oil, and the plasticizer accounts for the mass percentage of the mixed powder 0.8wt%;

[0046] Step 4: Use Nb fibers with a wire diameter of 600 μm to prefabricate the skeleton structure to form...

Embodiment 2

[0053] A preparation method of a three-dimensional fiber skeleton toughened cermet of the present invention comprises the following steps:

[0054] Step 1, weigh WC powder 70% and Cr with an average particle size of 5 μm according to mass percentage 2 C 3 15% powder, 5% Nb powder with an average particle size of 5 μm, 10% cast iron powder (HT300) with a particle size of 5 μm, the sum of the volume percentages of the above components is 100%; the purity of the above powders is greater than 99%;

[0055] Step 2: using a ball mill to mix the powder weighed in step 1 evenly to form a mixed powder;

[0056] Step 3: Add a small amount of plasticizer to the mixed powder, and then put it into a mixer for plasticization and granulation to form a mixed material; wherein, the plasticizer is paraffin oil, and the plasticizer accounts for the mass percentage of the mixed powder 0.7wt%;

[0057] Step 4: using metal Nb fibers with a wire diameter of 500 μm to prefabricate the skeleton str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com