High Zn content, superstrength and supertoughness, high destroy limit type aluminium alloy material and preparation method

A technology of aluminum alloy material and damage tolerance, applied in the field of aluminum alloy, can solve the problem of not forming a patent, and achieve the effect of high plasticity and damage tolerance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

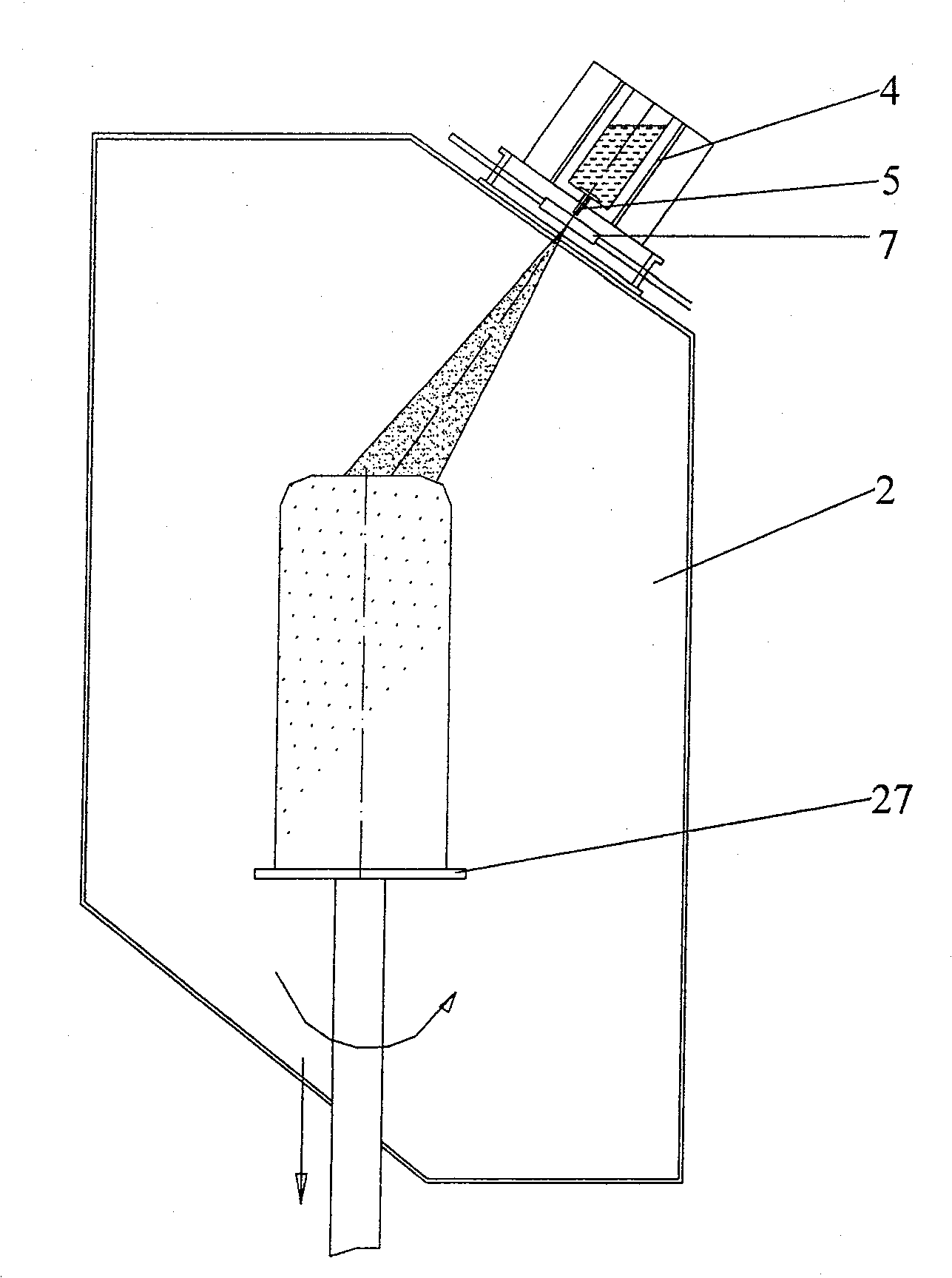

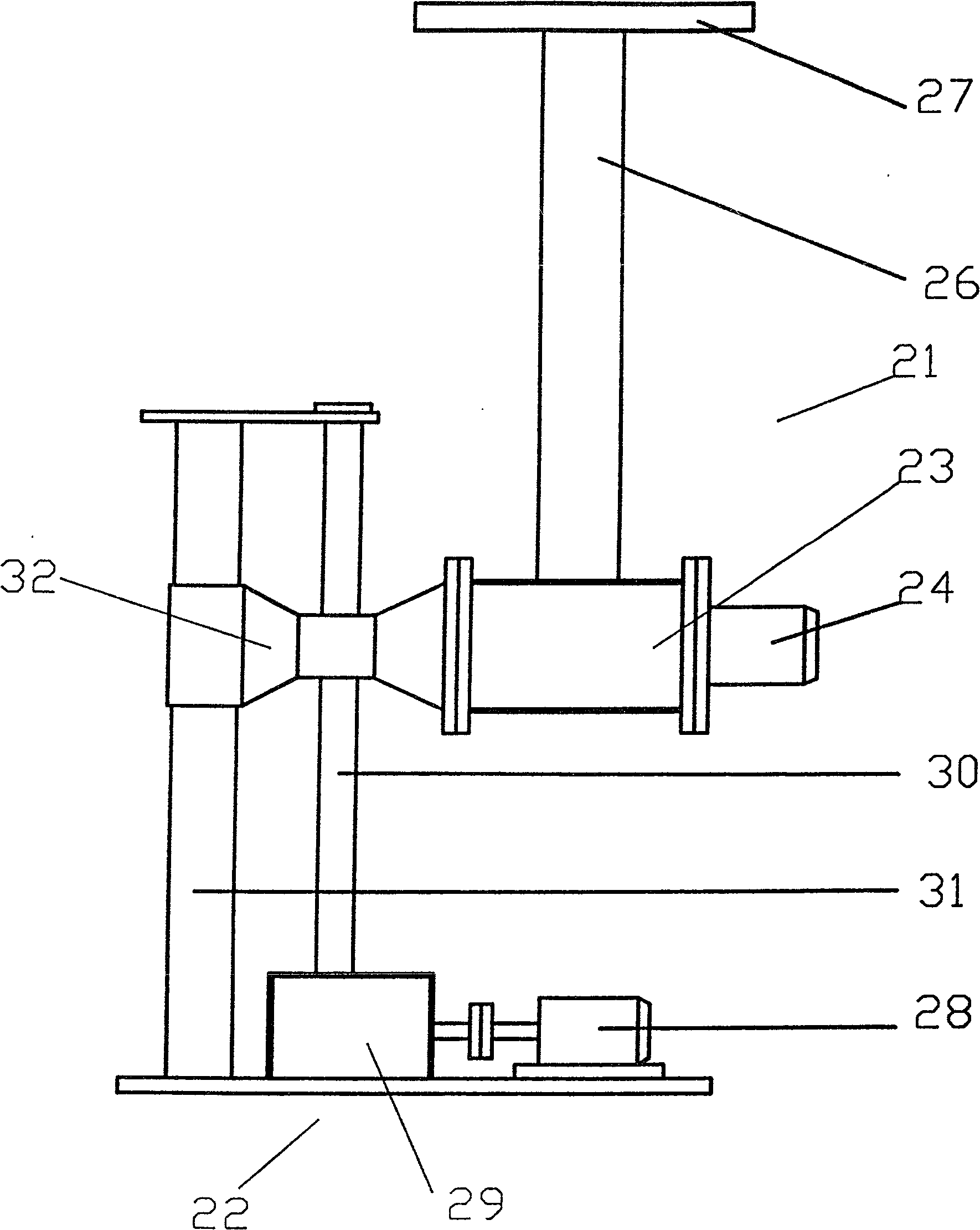

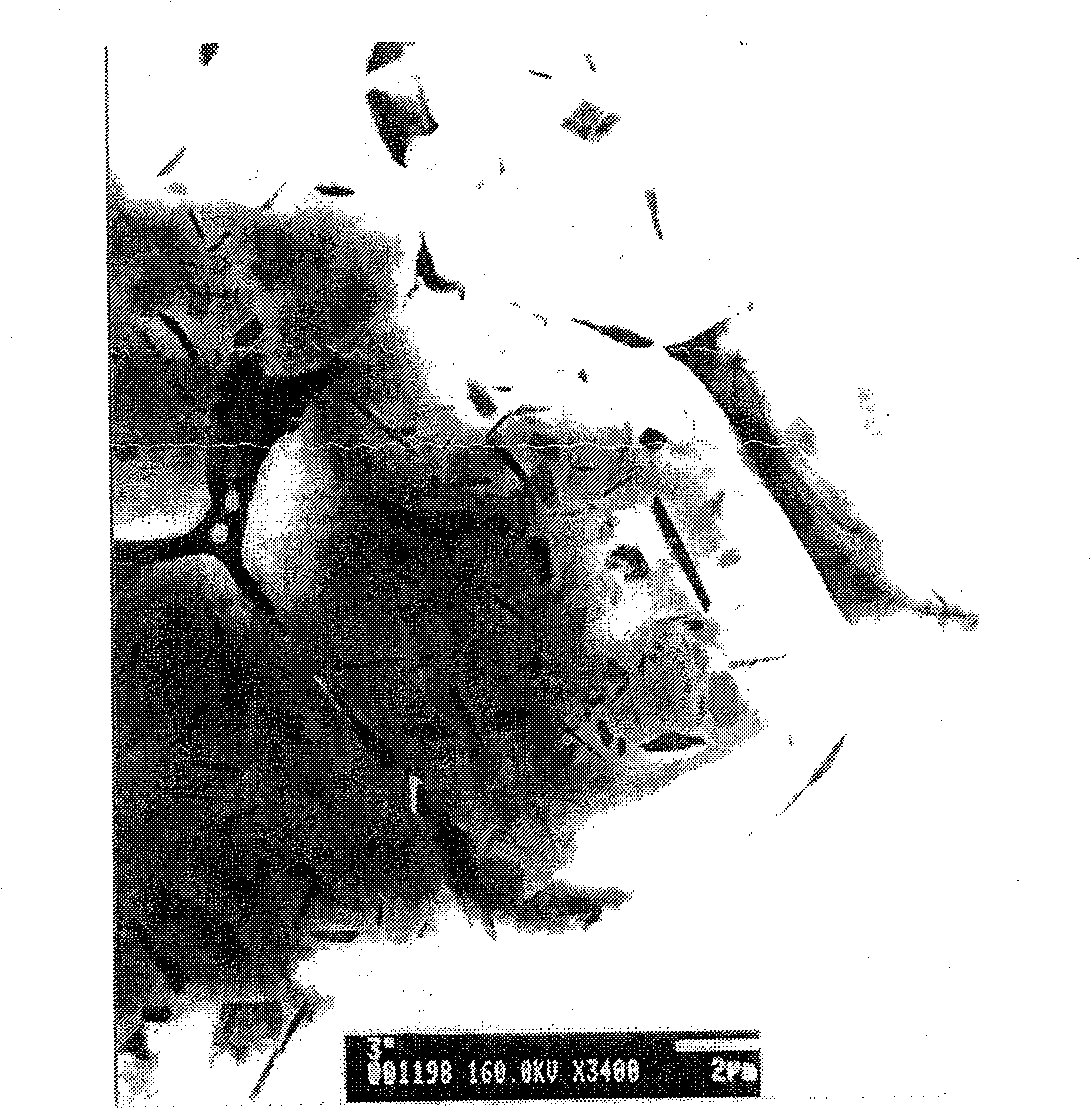

[0047] The alloy composition is Zn 10wt%, Mg 2.5wt%, Cu 1.7%, Zr 0.5%, Fe figure 2 As shown, turn on the rotating motor 24 and the lifting motor 28, and rotate the receiving tray at a high speed at a speed of 60 to 120 rpm. The angle at which the receiving tray is pulled down is 35 degrees to the vertical line of the horizontal plane, and the speed of the pull-down is 20-30mm / min. A receiving tray 27, so that the atomized liquid droplets are directly deposited on the receiving tray 27. Continuously atomize 150 kg of new alloy at one time, and prepare a new type of high-strength and high-toughness aluminum alloy round ingot weighing 100Kg. The photo of the prepared round ingot is as follows Figure 4 shown. Process the deposited billet into a billet of a certain specification, keep it warm at 410°C for 2 hours, and perform hot extrusion processing with an extrusion ratio of 24:1 to extrude a φ30mm round bar, 440°C / 1h+480°C / 1.5 h solid solution treatment, the aging system adopt...

Embodiment 2

[0051] Zn 9wt%, Mg 2.0wt%, Cu1.3%, Zr 0.2%, FeIC (MPa*m 1 / 2 )=34, da / dN≤6×10 -3 mm / cycle.

Embodiment 3

[0053] 9.5wt% Zn, 2.3wt% Mg, 1.5% Cu, 0.4% Zr, FeIC (MPa*m 1 / 2 )=34, da / dN≤6×10 -3 mm / cycle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate tensile strength | aaaaa | aaaaa |

| Fatigue limit | aaaaa | aaaaa |

| Fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com