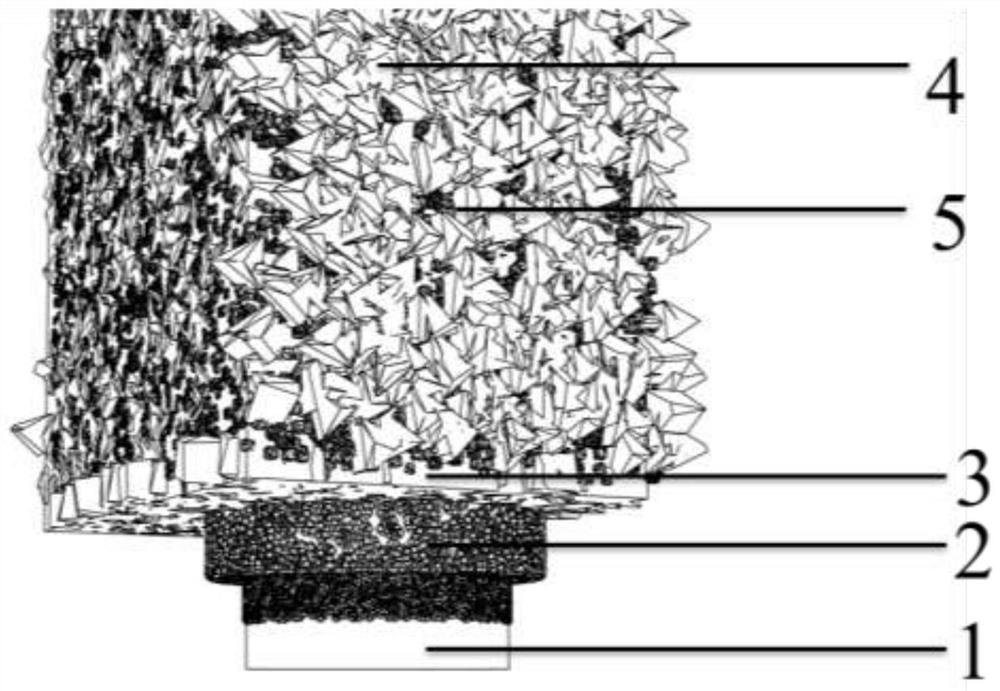

A multi-scale self-lubricating tungsten carbide matrix composite material and its preparation method

A tungsten carbide-based, composite material technology, applied in the field of metal-ceramic composite materials, can solve the problems of fracture failure frequency and poor toughness, and achieve the effect of improving toughness, high-efficiency fiber toughening, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a multi-scale self-lubricating tungsten carbide-based composite material of the present invention comprises the following steps:

[0034] Step 1, weigh the following components respectively: WC particles, Fe powder, Nb powder, graphite powder and MoS 2 powder; wherein, the mass percentage of WC particles is 53-76%, the mass percentage of Fe powder is 3.1-14%, the mass percentage of Nb powder is 9.5-19%, the mass percentage of graphite powder is 0.2-4.5%, MoS 2 The mass percentage of the above components is 4.5-13%, and the sum of the mass percentages of the above components is 100%;

[0035] Step 2: WC particles, Fe powder, Nb powder, graphite powder and MoS 2 The powder is mixed evenly to form a mixed powder;

[0036] Step 3: Add an appropriate amount of paraffin wax powder to the mixed powder in step 2, put it into a mixer for mixing treatment, and form a uniform material; wherein, the particle size of the paraffin wax powder is about 25 μm, a...

Embodiment 1

[0041] The preparation of a multi-scale self-lubricating tungsten carbide matrix composite material comprises the following steps:

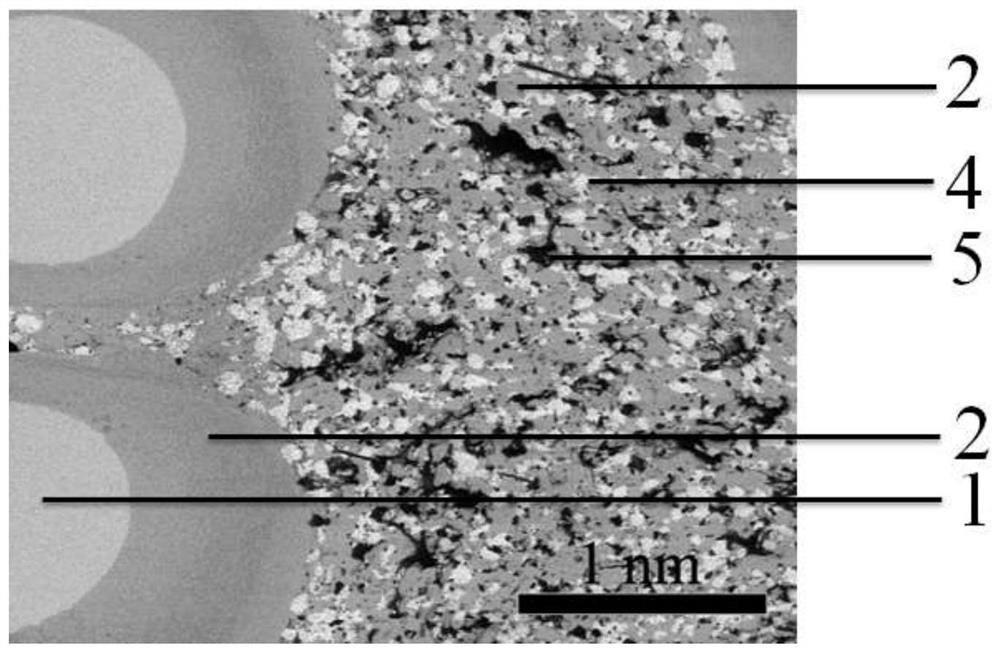

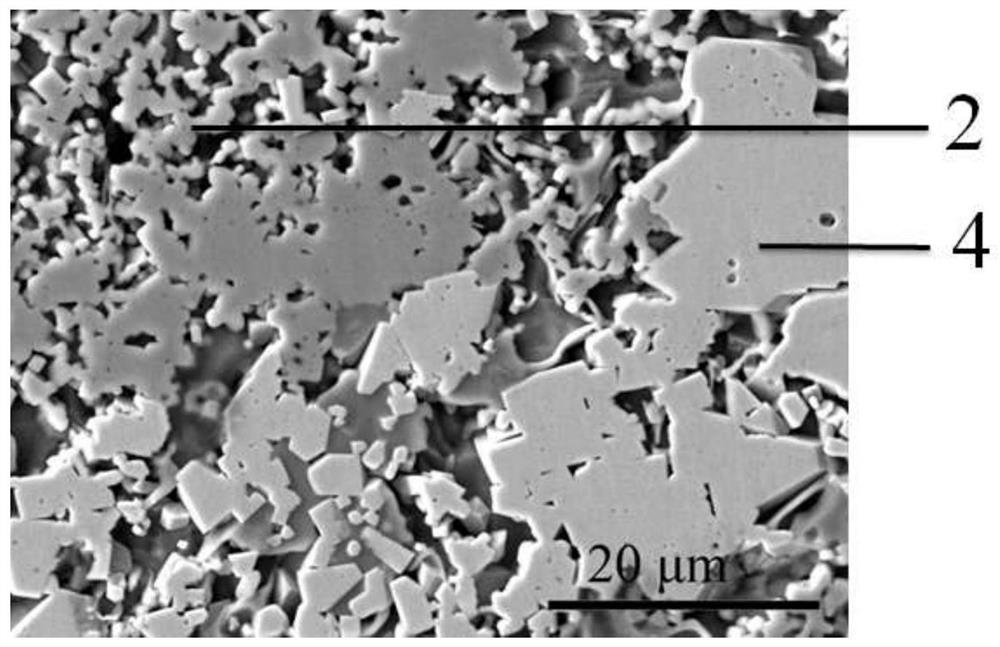

[0042] Step 1, weigh the following components respectively: WC particles, Fe powder, Nb powder, graphite powder and MoS 2Powder; the average particle size of WC particles is 20 μm, the average particle size of Fe powder is 1 μm, the average particle size of Nb powder is 1 μm, and the purity of the above powders is greater than 99.5%; wherein, the mass fraction of WC is 53%, and the mass fraction of Fe powder is Fraction 13%, mass fraction of Nb powder is 19%, mass fraction of graphite powder is 4.5%, MoS 2 The mass fraction of is 10.5%, and the sum of the mass percentages of the above components is 100%;

[0043] Step 2: Use a low-energy mixer to weigh the WC particles, Fe powder, Nb powder, graphite powder and MoS in step 1 2 The powder is mixed evenly to form a mixed powder, so that the graphite can evenly adhere to the surface of the metal p...

Embodiment 2

[0052] The preparation of a multi-scale self-lubricating tungsten carbide matrix composite material comprises the following steps:

[0053] Step 1, weigh the following components respectively: WC particles, Fe powder, Nb powder, graphite powder and MoS 2 powder; the average particle size of WC particles is 30 μm, the average particle size of Fe powder is 1 μm, the average particle size of Nb powder is 5 μm, MoS 2 The average particle size of the powder is 1 μm, and the purity of the above metal powders is greater than 99.5%. Among them, the mass fraction of WC is 76%, the mass fraction of Fe powder is 5%, the mass fraction of Nb powder is 13.9%, and the mass fraction of graphite powder 0.2%, MoS 2 The mass fraction of is 4.9%;

[0054] Step 2: Use a low-energy ball mill to weigh the WC particles, Fe powder, Nb powder, graphite powder and MoS in step 1 2 The powder is mixed evenly to form a mixed powder, so that the graphite can evenly adhere to the surface of the metal part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com