A kind of preparation method of al-cu-li-x series aluminum-lithium alloy sheet

An al-cu-li-x, aluminum-lithium alloy technology, which is applied in the field of aluminum-lithium alloy sheet preparation technology, can solve the problems of sheet dimensional accuracy, the surface quality of the sheet cannot meet the requirements of use, etc., and achieves forming performance and damage tolerance. The effect of improved performance, high dimensional accuracy, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

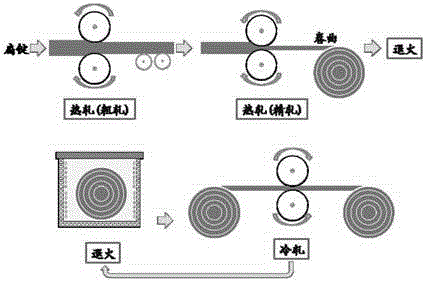

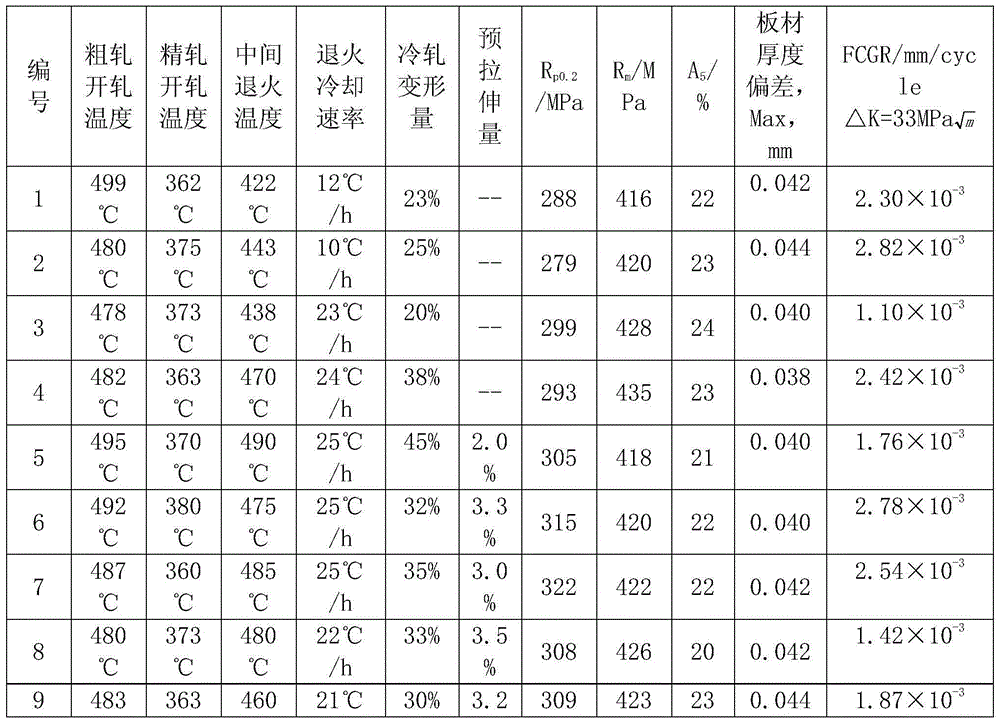

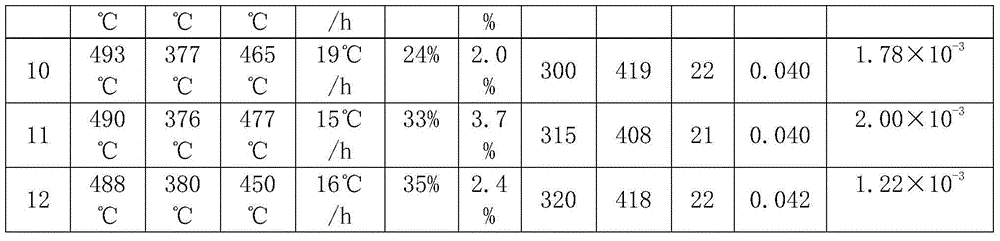

[0026] Produce qualified Al-Cu-Li-X series aluminum-lithium alloy ingots, the chemical composition and weight percentage of the alloy are: Cu2.0-3.0%, Li1.8-2.6%. Zr0.04~0.20%, Mg0.20%~1.20%, Ag0.1~0.9%, Si≤0.10%, Fe≤0.10%, Ti≤0.12%, other impurities individually≤0.05%, total≤0.15%, The balance is Al, see attached figure 1 As shown, the process of using this alloy to process thin plates is as follows:

[0027] ⑴Hot rolling, hot rolling the slab after homogenization treatment, the rolling temperature is 480~500℃;

[0028] (2) Hot finish rolling, hot finish rolling the hot-rolled plate to any specification with a thickness of 4.0mm~8.0mm, the hot finish rolling temperature is 280℃~380℃, and then coiled into coils for preparation before cold rolling;

[0029] (3) Carry out high-temperature annealing treatment on the plate after hot finish rolling. The annealing temperature is 421°C-490°C, the holding time is 0.5-4.0h, and it is cooled to about 200°C with the furnace and taken o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com