Vacuum heat insulation material and cold reserving apparatus with the same

A technology of vacuum insulation materials and equipment, which can be used in heat exchange equipment, mechanical equipment, and pipelines through thermal insulation protection, etc., and can solve the problems of reduced thermal insulation performance and insufficient gas barrier properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

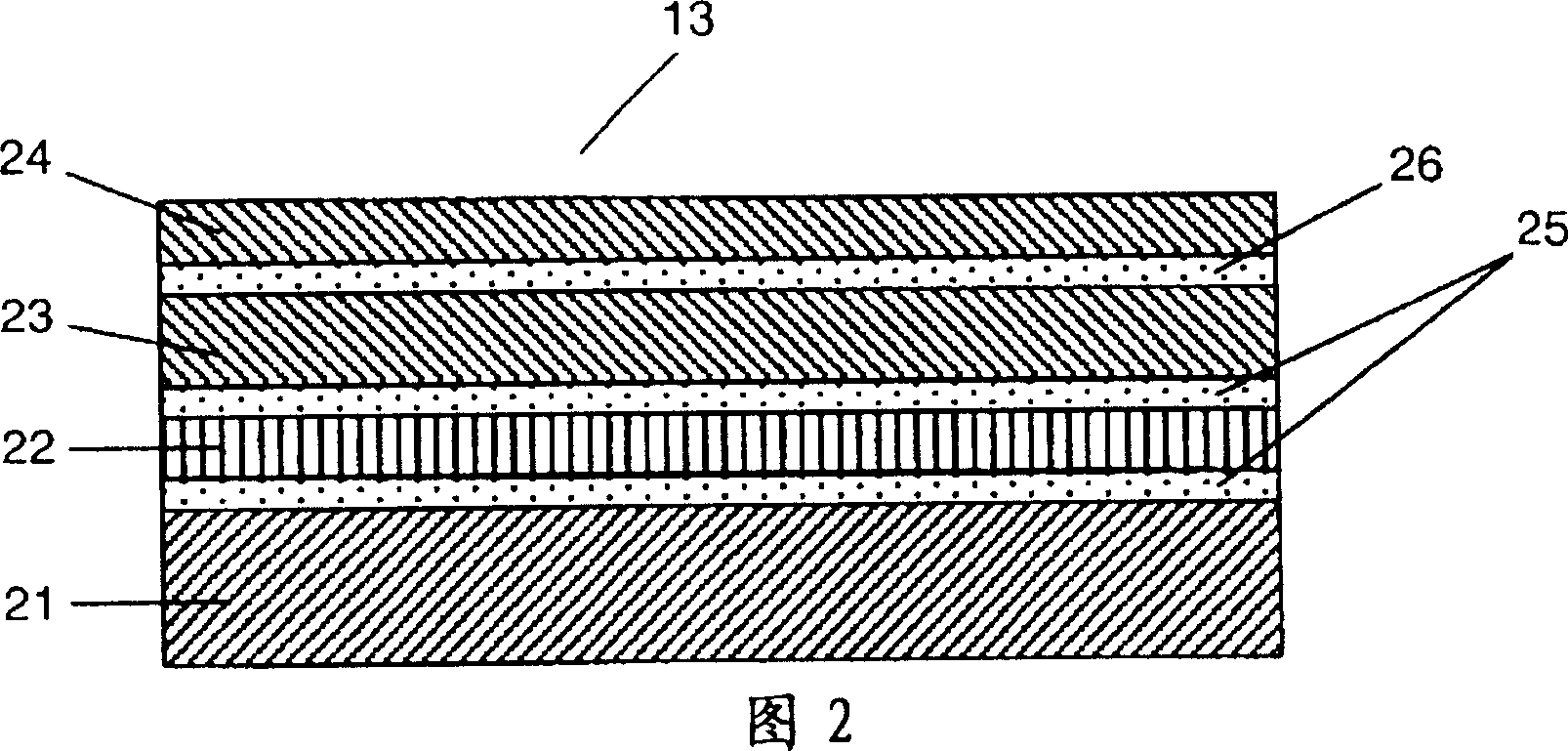

[0248] The polyurethane resin constituting the adhesive layer 26 shown in FIG. 10 is a polyurethane resin containing a modified product of aliphatic polyester polyol and hexamethylene diisocyanate (HDI) which is an aliphatic polyisocyanate.

[0249] At this time, the elastic modulus of the polyurethane resin of the adhesive layer 26 is smaller than the elastic modulus of each film constituting the outer cover material 13 . In addition, the surface hardness of the polyurethane resin was lower at 20°C, 40, and there was no difference in surface hardness at 20°C and 0°C.

[0250] The vacuum heat insulating material having the above structure has no problems such as occurrence of pinholes and peeling of the outer covering material.

[0251] In addition, known aliphatic polyisocyanates can be used as the aliphatic polyisocyanate, but preferably hexamethylene diisocyanate (HDI), trimethylhexamethylene diisocyanate (TMDI), lysine diisocyanate (LDI), etc., are more preferably modifie...

Embodiment 2

[0254] The adhesive layer 26 in FIG. 10 is made of a polyurethane resin containing a modified form of isophorone diisocyanate (IPDI) which is an aliphatic polyester polyol and an alicyclic isocyanate. The compounding ratio is that the equivalent ratio of polyisocyanate to polyol is 2, and the polyisocyanate is excessive.

[0255] At this time, the elastic modulus of the urethane resin of the adhesive layer 26 is smaller than the elastic modulus of each film constituting the outer cover material 13 . In addition, the surface hardness of the polyurethane resin was as low as 40 at 20°C, and there was no difference in the surface hardness at 20°C and 0°C.

[0256] The vacuum heat insulating material having the above structure has no problems such as occurrence of pinholes and peeling of the outer covering material.

[0257] In addition, when an aliphatic isocyanate cannot be used, it is effective to use an alicyclic isocyanate appropriately. In this case, it is preferable that th...

Embodiment 3

[0261] The adhesive layer 26 is made of a polyurethane resin containing a modified form of aliphatic polyester polyol and dicyclohexylmethane diisocyanate (HMDI), which is an alicyclic isocyanate. The compounding ratio is that the equivalent ratio of polyisocyanate to polyol is 2, and the polyisocyanate is excessive.

[0262] At this time, the elastic modulus of the urethane resin of the adhesive layer 26 is smaller than the elastic modulus of each film constituting the outer cover material 13 . In addition, the surface hardness of the polyurethane resin was 45 (20° C.) and 46 (0° C.).

[0263] The vacuum heat insulating material having the above-mentioned structure does not have problems such as generation of pinholes and peeling of the outer covering material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com