Bone implant and method of securing

a bone implant and bone cement technology, applied in the field of implants and methods of securing implants to bone, can solve the problems of cracking of bone cement slabs, deformation of bone cement, and cracks often initiating at the site of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

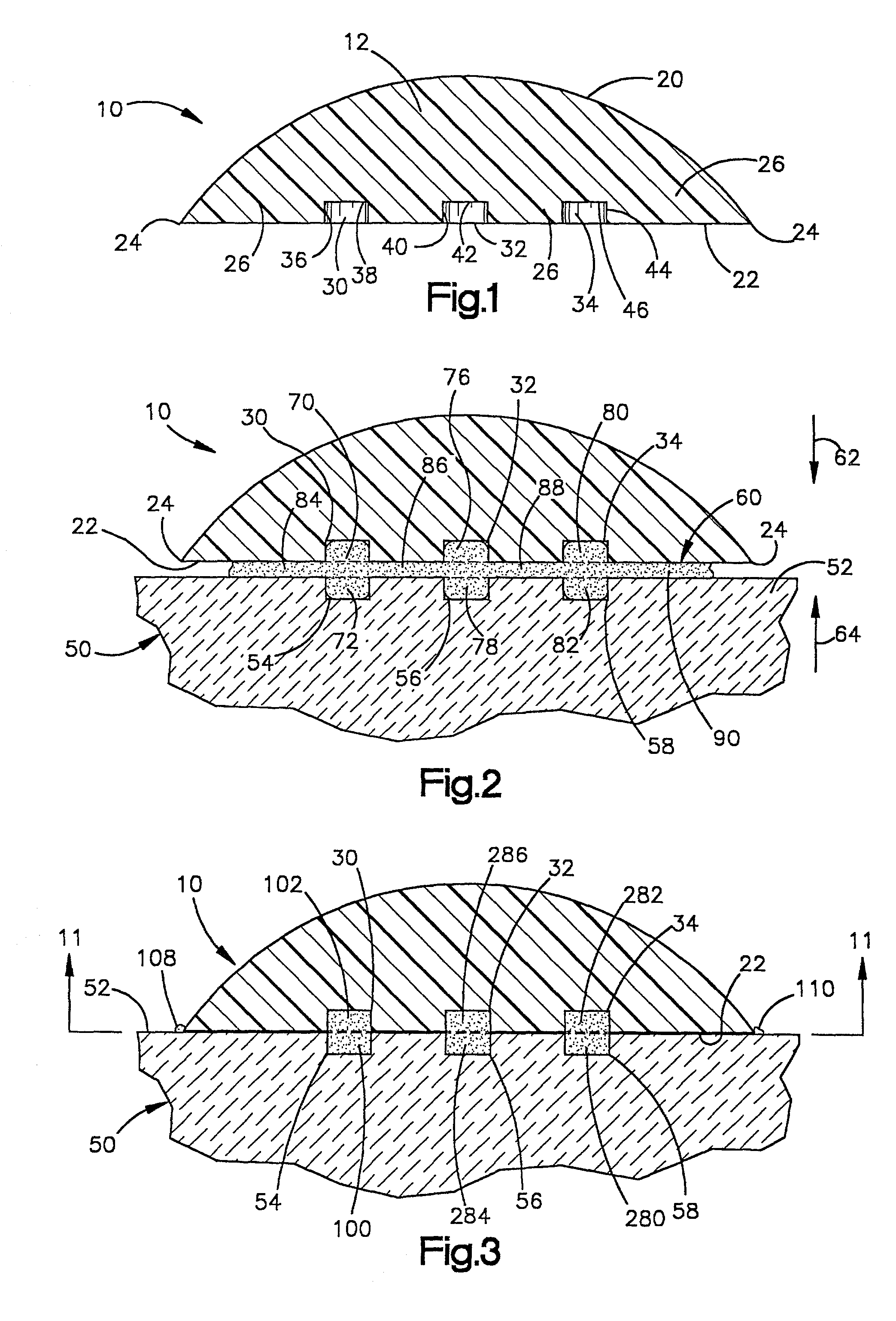

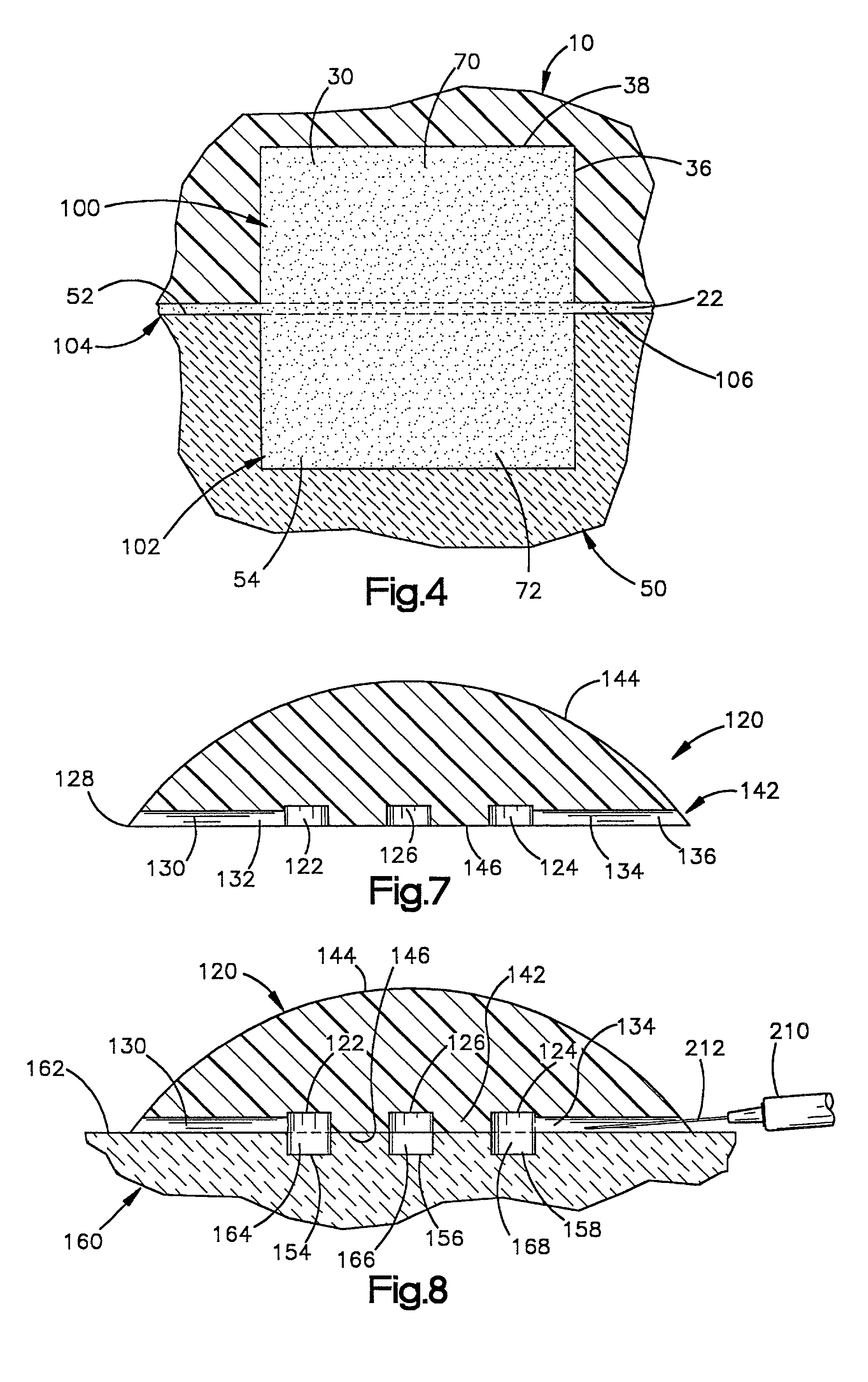

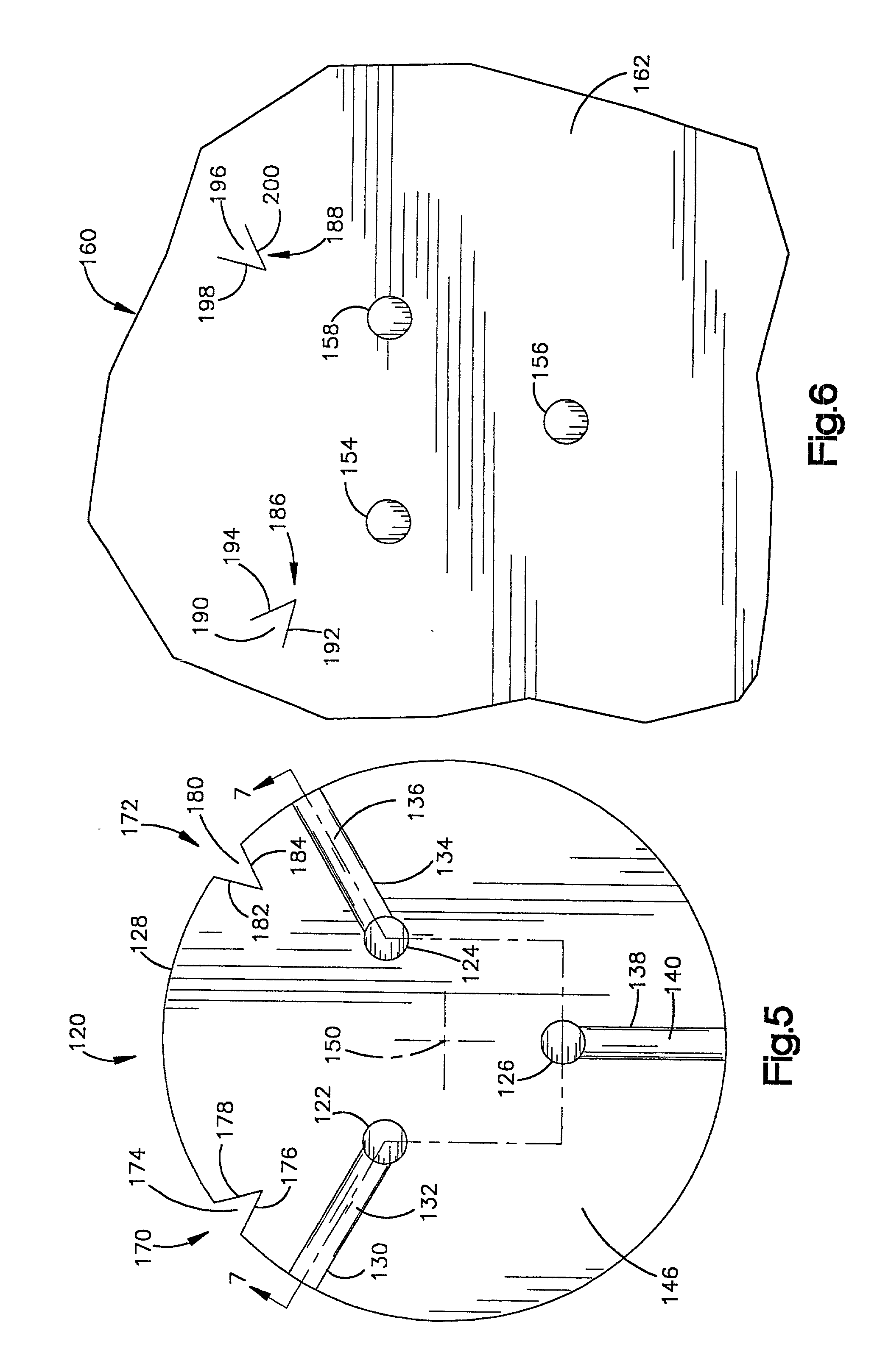

[0030] The present invention relates to an implant and to a method of securing an implant to a bone with bone cement. The present invention is applicable to various implant constructions. As representative of the present invention, FIG. 1 illustrates a patellar implant 10. The implant 10 is made of a body of material 12. The material 12 is preferably a biocompatible plastic material. A preferred material is ultra high molecular weight polyethylene (UHMWPE). Alternatively, the implant 10 can be a metal backed plastic component having a bone engagement portion made of metal and an articulating surface made of plastic.

[0031] The implant 10 has an arcuate articulating surface 20 and a planar bone engagement surface 22. The surfaces 20 and 22 intersect at the outer periphery 24 of the implant 10.

[0032] A bone engagement portion 26 of the implant 10 includes the portion of the implant 10 adjacent to or close to the bone engagement surface 22. The bone engagement portion 26 includes surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com