Semiconductor Device And Process For Producing Semiconductor Device

A device manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as product reliability decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

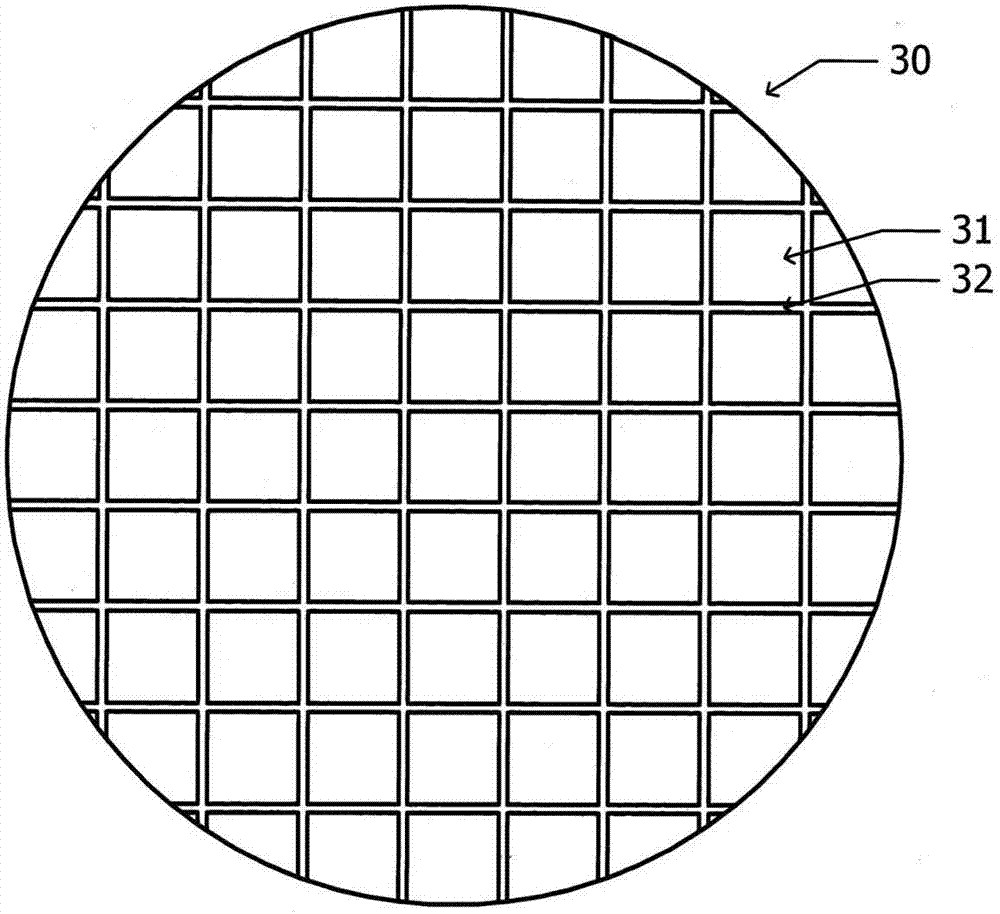

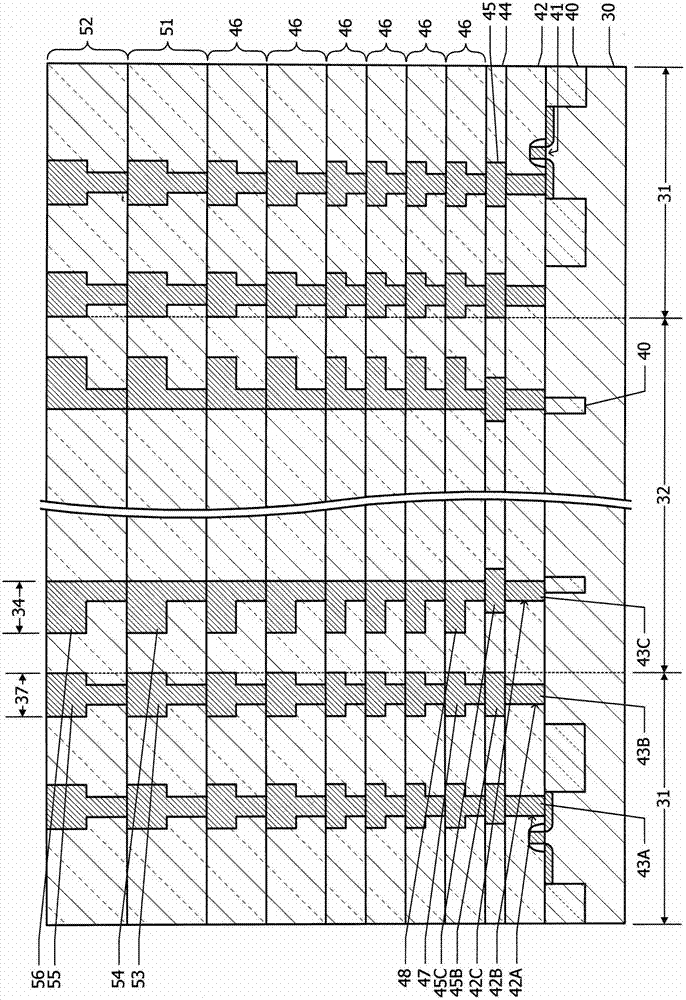

[0014] Figure 1A is a plan view showing a semiconductor wafer (30) used for the semiconductor device of Example 1. For example, a silicon wafer is used as the semiconductor wafer (30). On the surface of a semiconductor wafer (30), a plurality of product areas (chip areas) (31) arranged in a matrix are defined. Between each product area (31), a dicing area (32) is secured. The planar shape of the scribe area is a square dot matrix.

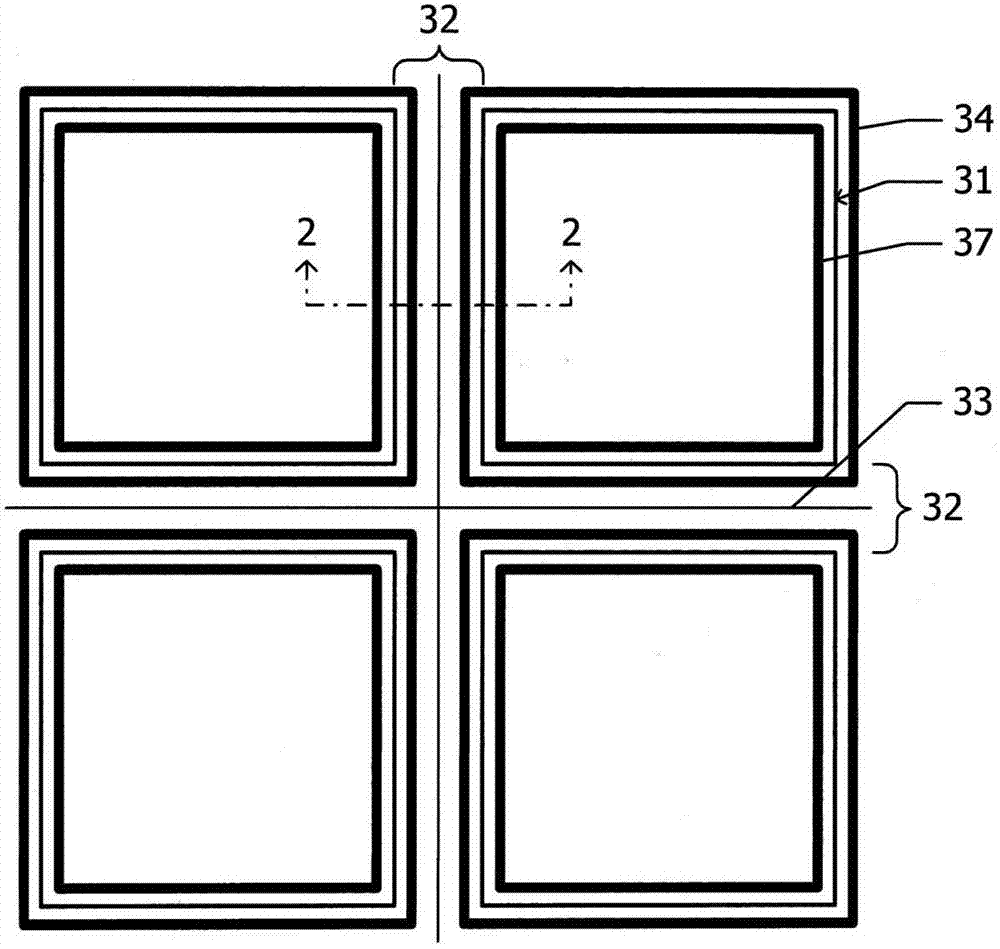

[0015] Figure 1B is a plan view showing some product areas (31 ) and some scribe areas (32). In the product area (31), a moisture-proof ring (37) is formed, and in the scribe area (32), a crack protection ring (34) is formed. Each crack protection ring (34) is arranged for each product zone (31) and surrounds the corresponding product zone (31). The planar shape of each product area (31) is rectangular or square, and the crack protection ring (34) includes a straight line extending parallel to each side of each product area (31). Each moist...

example 2

[0067] Figure 20 is a cross-sectional view showing the semiconductor device of Example 2 during the manufacturing process. Figure 20 The structure shown in Example 1 corresponds to the Figure 5 The structure of the steps shown in . In Example 1, one crack protection ring (34) is formed for each product area (31). In Example 2, outside the crack guard ring (34), a second crack guard ring (110) is formed to surround the crack guard ring (34) in plan view. The layered structure of the crack protection ring (110) is the same as that of the crack protection ring (34) on the inner peripheral side. That is, the crack guard ring (110) includes a metal film (114) in the wiring layer (52). Over the metal film (114), a metal film (113) functioning as an etching mask is arranged.

[0068] Grooves (111) and (112) are formed on the inner peripheral side and the outer peripheral side of the crack protection ring (110), respectively. Grooves ( 111 ) and ( 112 ) are formed in the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com