Multi-degree-of-freedom mechanical arm capable of being equipped on small and medium-sized mobile platforms

A mobile platform, small and medium-sized technology, applied in the field of robotic arms, can solve problems such as the inability of small and medium-sized robotic arms to grasp objects accurately, increase the applicability of robotic arms, etc., to improve reliability and life, and reduce jitter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

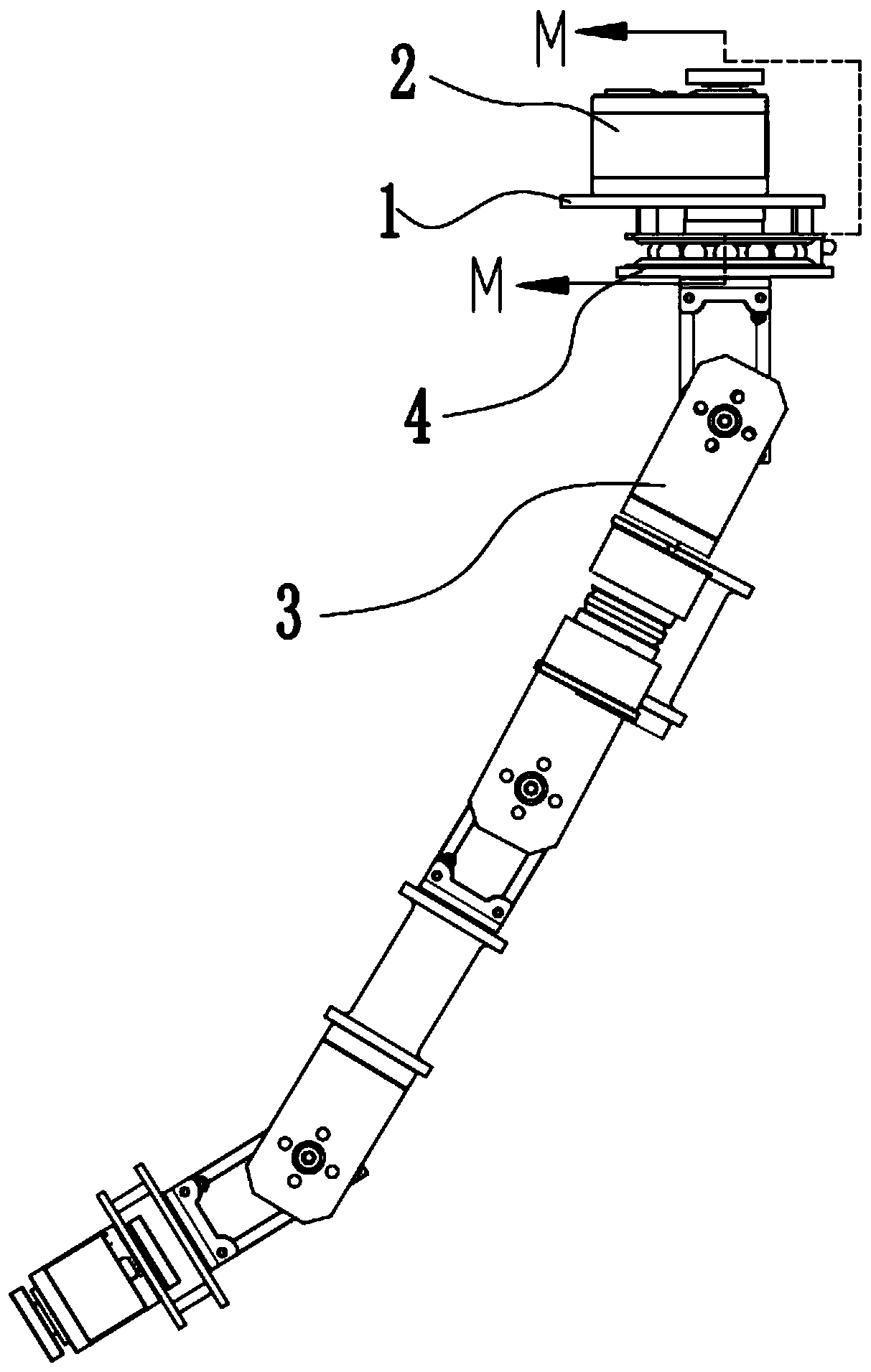

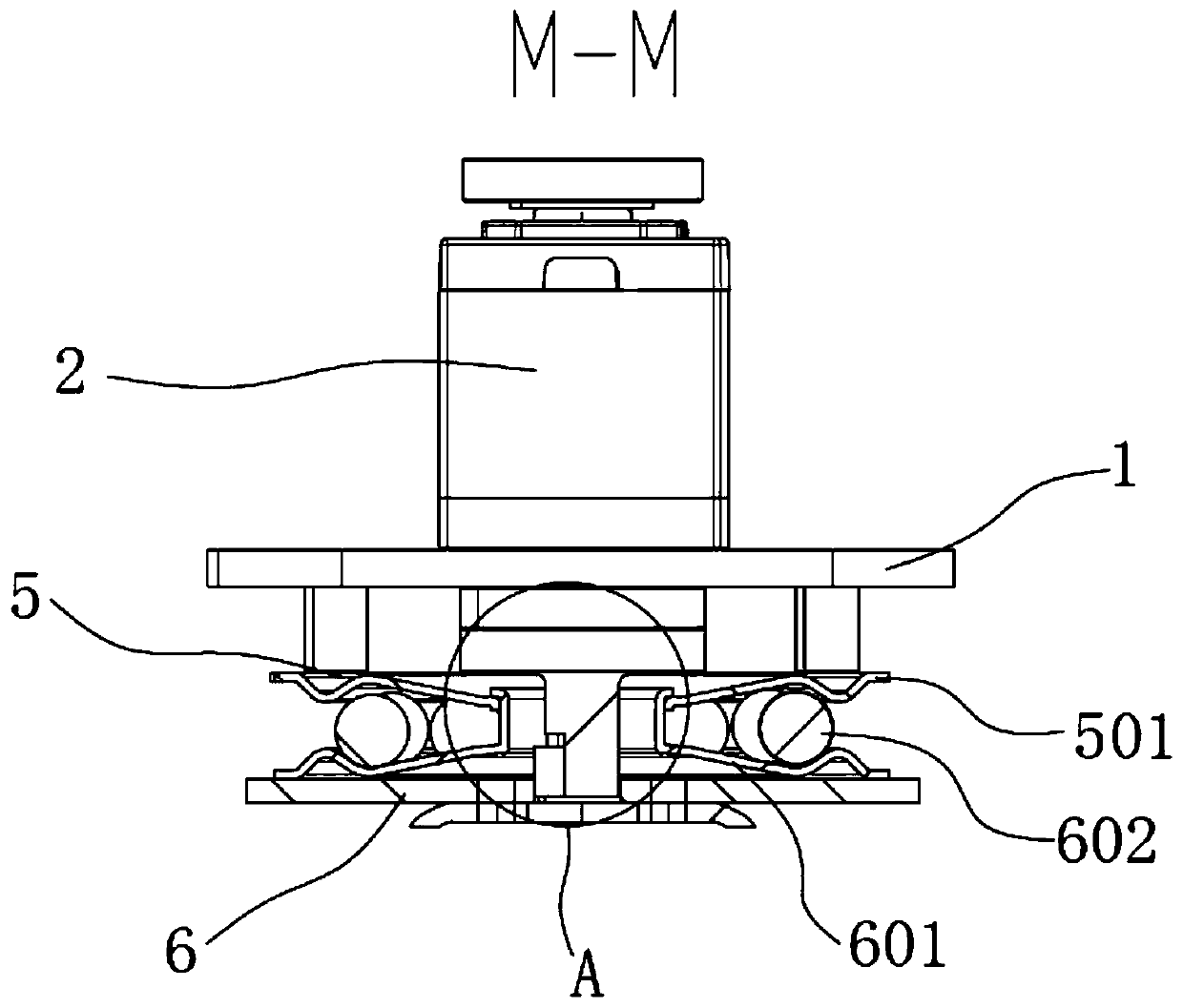

[0030] Such as Figure 1-3 Shown is an embodiment of a multi-degree-of-freedom robot arm that can be equipped on a small and medium-sized mobile platform, including a base 1, a first steering gear 2 installed on the base 1, connecting the first steering gear 2 and several stages of connecting arms 3 The turntable 4 includes a fixed disk 5 fixedly connected to the base 1 , and a rotating disk 6 rotatably connected to the fixed disk 5 , and the rotating disk 6 is connected to the output shaft 201 of the first steering gear 2 .

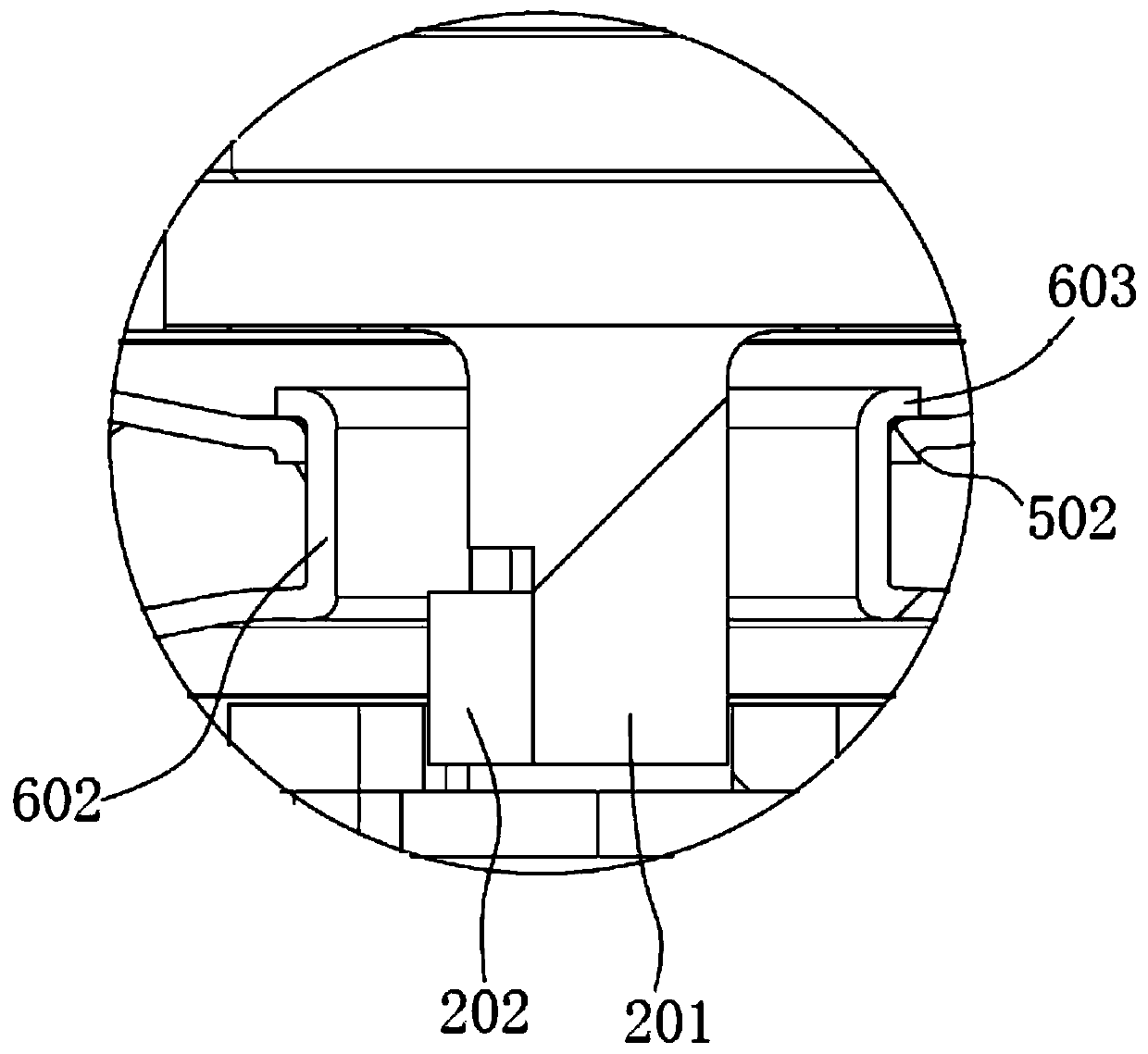

[0031]Wherein, the rotating disk 6 is provided with a rotating metal sheet 601, and the fixed disk 5 is provided with a fixed metal sheet 501; the fixed metal sheet 501 is provided with a central hole 502, and the rotating metal sheet 601 is provided with a hollow portion 602 sleeved in the central hole 502, and the hollow portion One end of 602 close to the fixing metal piece 501 is provided with an extension portion 603 that is engaged with the fixing ...

Embodiment 2

[0037] Figure 4 Shown is another embodiment of a multi-degree-of-freedom robot arm that can be equipped on a small and medium-sized mobile platform. Two connecting arm 9 and the third connecting arm 10; The link part A701 of the U-shaped arm 802 and the second U-shaped arm 803; the second connecting arm 9 includes a third steering gear 901 connected with the second U-shaped arm 803, and a connecting rod part B702 connected with the third steering gear 901 And the third U-shaped arm 902 connected with the link part B702; the third connecting arm 10 includes the fourth steering gear 1001 connected with the third U-shaped arm 902, the fifth steering gear 1001 connected with the fourth steering gear 1001 through the connecting plate 1002 Machine 1003. Both the link part A701 and the link part B702 have the same structure, and are actually link parts 7 installed at different positions. The second steering gear, the third steering gear and the fourth steering gear swing in the v...

Embodiment 3

[0045] Figure 7 Shown is another embodiment of the connecting rod part. On the basis of embodiment 2, the structure of the connecting rod part is further defined. The difference from embodiment 2 is that the end surface of the base 701 close to the shaft sleeve 7021 is provided with a block 7012, the shaft sleeve 7021 is provided with a slot 7025 for matching with the block 7012. During installation, the block 7012 is inserted into the slot 7025, and the base 701 and the sleeve 7021 are placed to move relative to each other.

[0046] The remaining features and working principle of this embodiment are consistent with Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com