Mechanical valve capable of switching air source in self-adaptive mode

An adaptive switching, mechanical technology, applied in the field of valve, to achieve the effect of improving life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

[0037] In order to solve the problem in the prior art that the engine high-pressure air is high-temperature and high-pressure when the engine is in a high state, and the use of external air with low bleed air pressure as the engine bleed air is likely to cause lubricating oil leakage in the bearing cavity, this application proposes a Adaptive switching origin of mechanical valves.

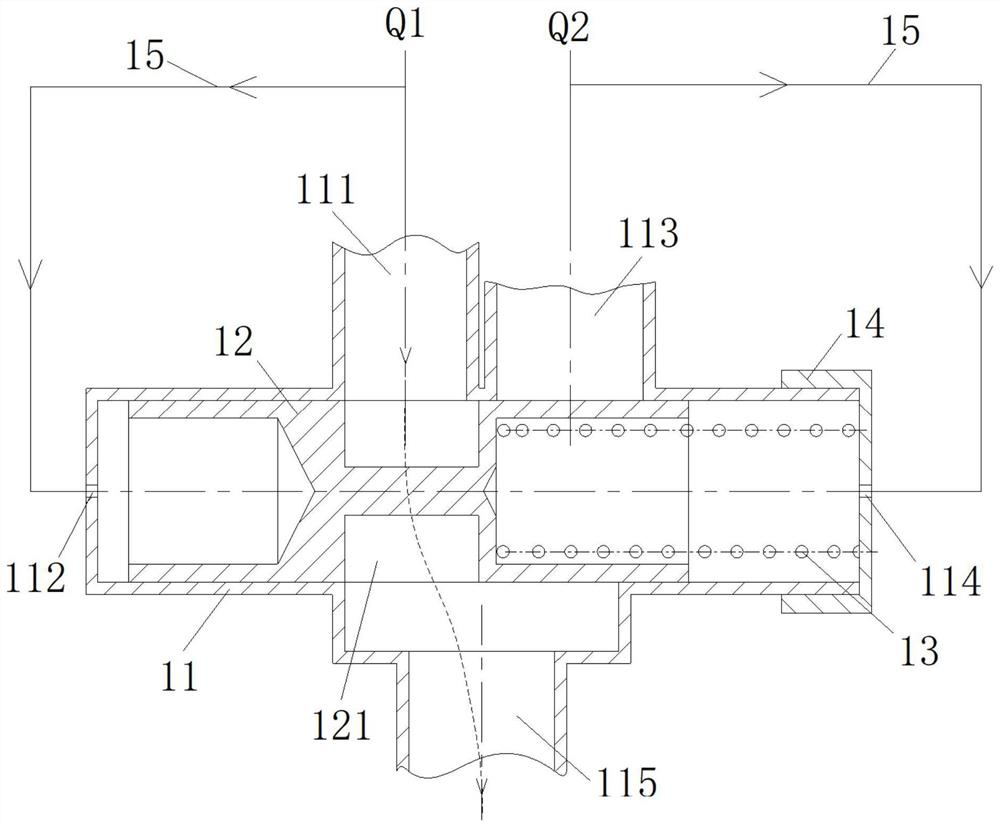

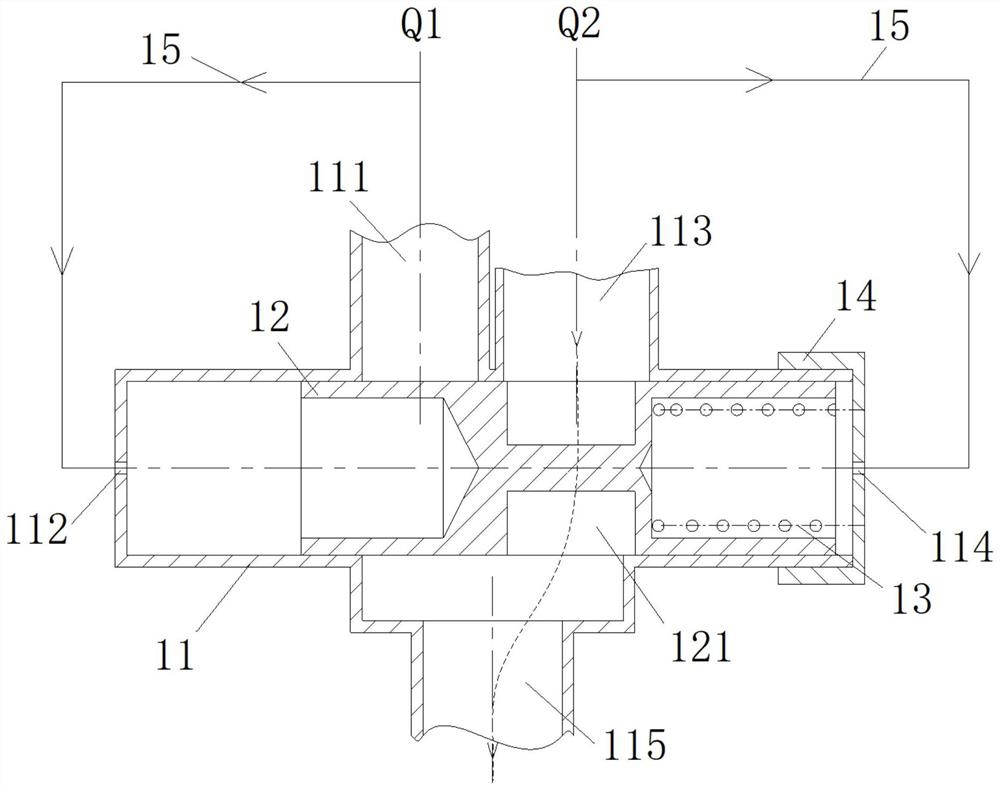

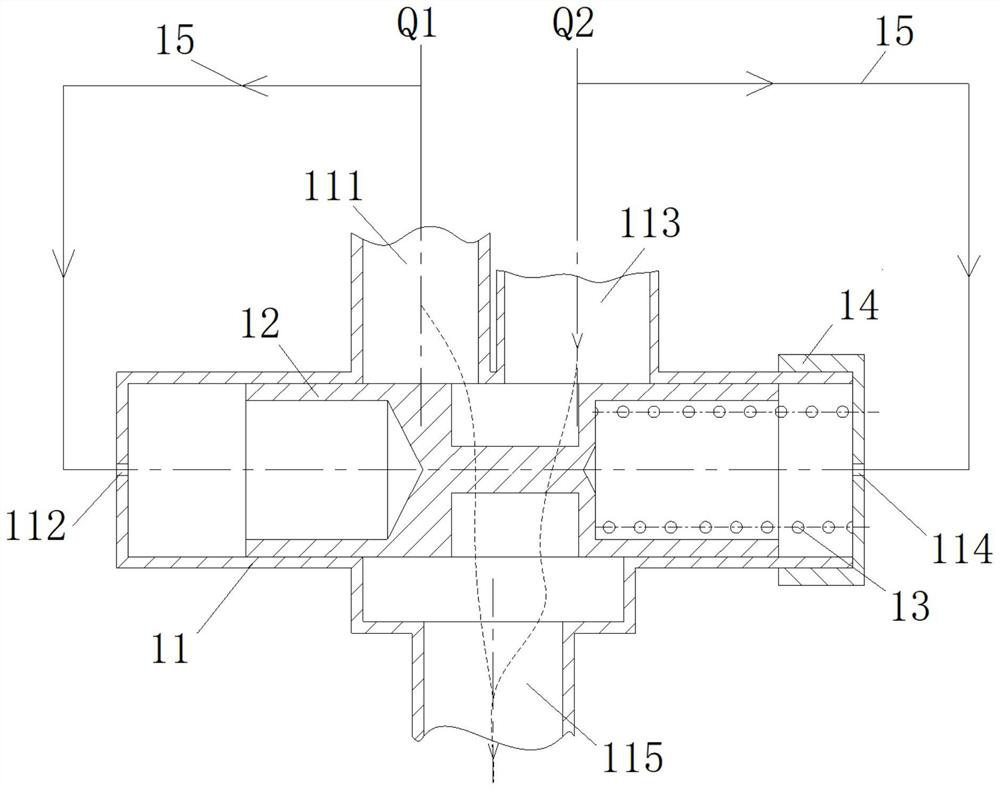

[0038] Such as Figure 1 to Figure 3 As shown, the mechanical valve provided in this application includes a housing 11 , a valve core 12 , a spring 13 and an end cap 14 .

[0039] Wherein, the casing 11 has a cavity, and the high-pressure air inlet 111 and the low-pressure air inlet 113 are adjacently connected to the cavity on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com