Wet type clutch with pressure stabilizing function

A wet clutch and clutch technology, applied in clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of unstable clutch pressure, worn friction plates, and short clutch life, so as to improve reliability and life, and improve service life. Longevity and wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

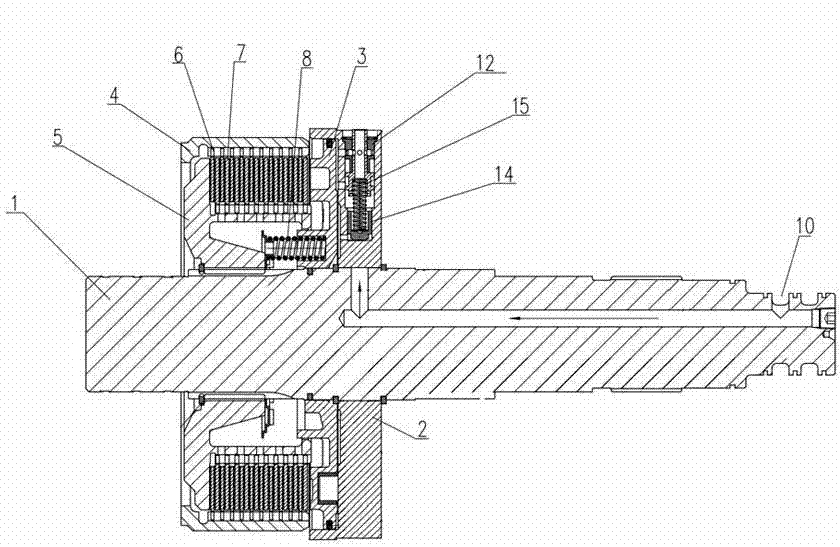

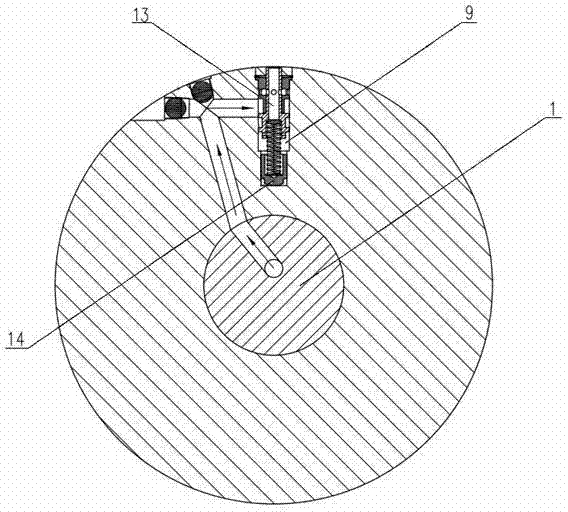

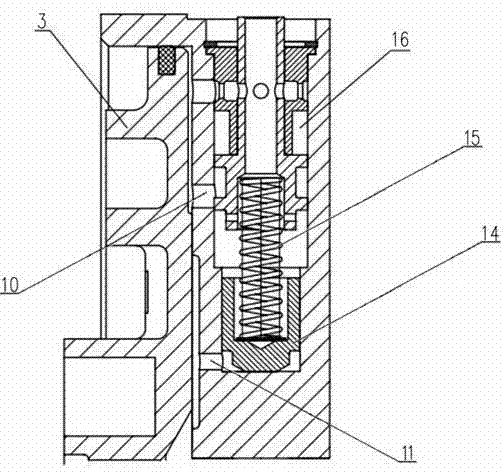

[0018] As shown in the figure, a wet clutch with a voltage stabilizing function includes a main shaft 1, a clutch piston cylinder 2, a clutch piston 3, a clutch outer hub 4, a clutch inner hub 5, a friction plate 6, a dual plate 7 and a spring assembly 8 , the main shaft 1 is in interference fit with the cylinder of the clutch piston cylinder 2, the clutch outer hub 4 is connected with the friction plate 6 through a spline, and the friction plate 6 is a paper-based friction plate. The dual plate 7 is splined to the clutch inner hub 5 . The main shaft 1 is provided with a hydraulic oil inlet 101, and both the main shaft 1 and the clutch piston cylinder 2 have built-in oil passages. The clutch piston cylinder 2 has a valve hole 9, and there is an oil inlet 10 and a feedback oil port 11 between the valve hole 9 and the piston cavity of the clutch piston cylinder 2. The wet clutch also includes an LD valve pressure stabilizing device, The LD valve voltage stabilizing device is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com