Large-channel semiconductor laser liquid refrigeration sheet and laser thereof

A refrigeration chip and semiconductor technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve problems such as blockage of microchannels, and achieve the effects of improving reliability and life, improving heat dissipation efficiency, and shortening heat conduction paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

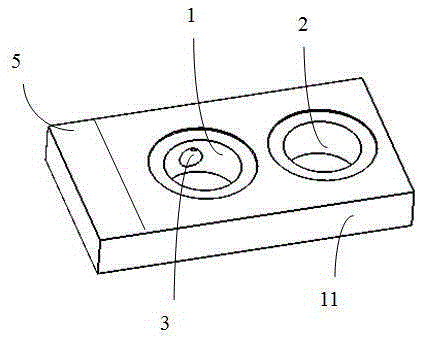

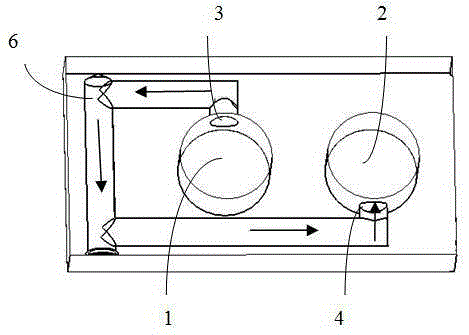

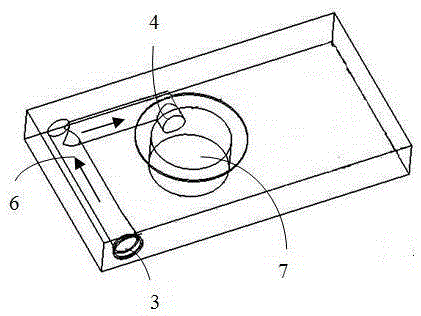

[0022] Such as figure 1 It is the liquid cooling sheet of the large-channel semiconductor laser of the present invention, including a sheet-shaped cooling sheet main body 11; the liquid inlet hole 1 and the liquid outlet hole 2 are arranged on the cooling sheet main body 11, and the liquid inlet hole 1 and the liquid outlet hole The holes 2 all pass through the upper surface and the lower surface of the main body 11 of the refrigerating sheet; a chip mounting area 5 is arranged on the end of the main body 11 of the refrigerating sheet near the liquid inlet hole 1 for installing a laser chip; There is a water inlet 3, a water outlet 4 is provided on the inner wall of the liquid outlet hole 2, and a tubular liquid cooling channel 6 is provided in the main body 11 of the cooling plate for connecting the water inlet 3 and the water outlet 4, and the liquid cooling channel 6 Starting from the water inlet 3, the path passes through the area between the chip mounting area 5 and the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com