Online coating mechanism of RFID tag bonding machine and using method of online coating mechanism

A technology of RFID tags and lamination mechanisms, applied in the field of RFID tags, can solve the problems of chip and antenna connection disconnection, internal circuit breakage, chip breakage, etc., to achieve the effect of improving life and reliability, controlling costs, and improving impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

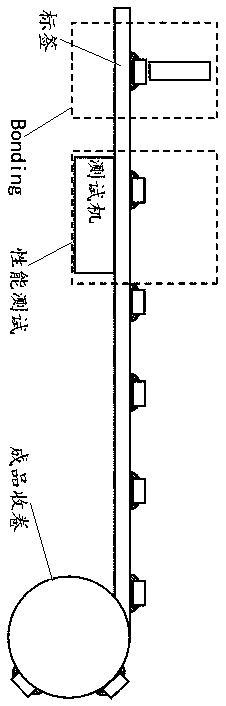

[0029] An RFID label bonding machine online lamination mechanism, including a frame 1 and a discharge shaft 2 connected to the frame, a waste collection shaft 3, a number of guide wheels, a pair of lamination pressing rollers 4, and the discharge shaft is placed in a Above the lamination pressing rollers, the waste collection shaft is placed on one side of the discharge shaft, and among a pair of lamination pressing rollers, the upper roller is connected with a cylinder 13, which can control the pressing and separation of the two rollers. A protective film 5 is wound on the discharge shaft. After the initial end of the protective film is guided by a number of guide wheels, the film body 6 at the initial end of the protective film is separated from the bottom paper 7. The separated bottom paper is wound on the waste collection shaft and separated. The final film body and the RFID tag are placed between a pair of laminating rollers for lamination to complete the lamination on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com