Devices for maintaining food products at low temperature

a technology for maintaining food products and food products, applied in the field of devices, can solve the problems that the full value and performance of the system will not be fully understood, and achieve the effects of low thermal conductivity, high reliability, and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

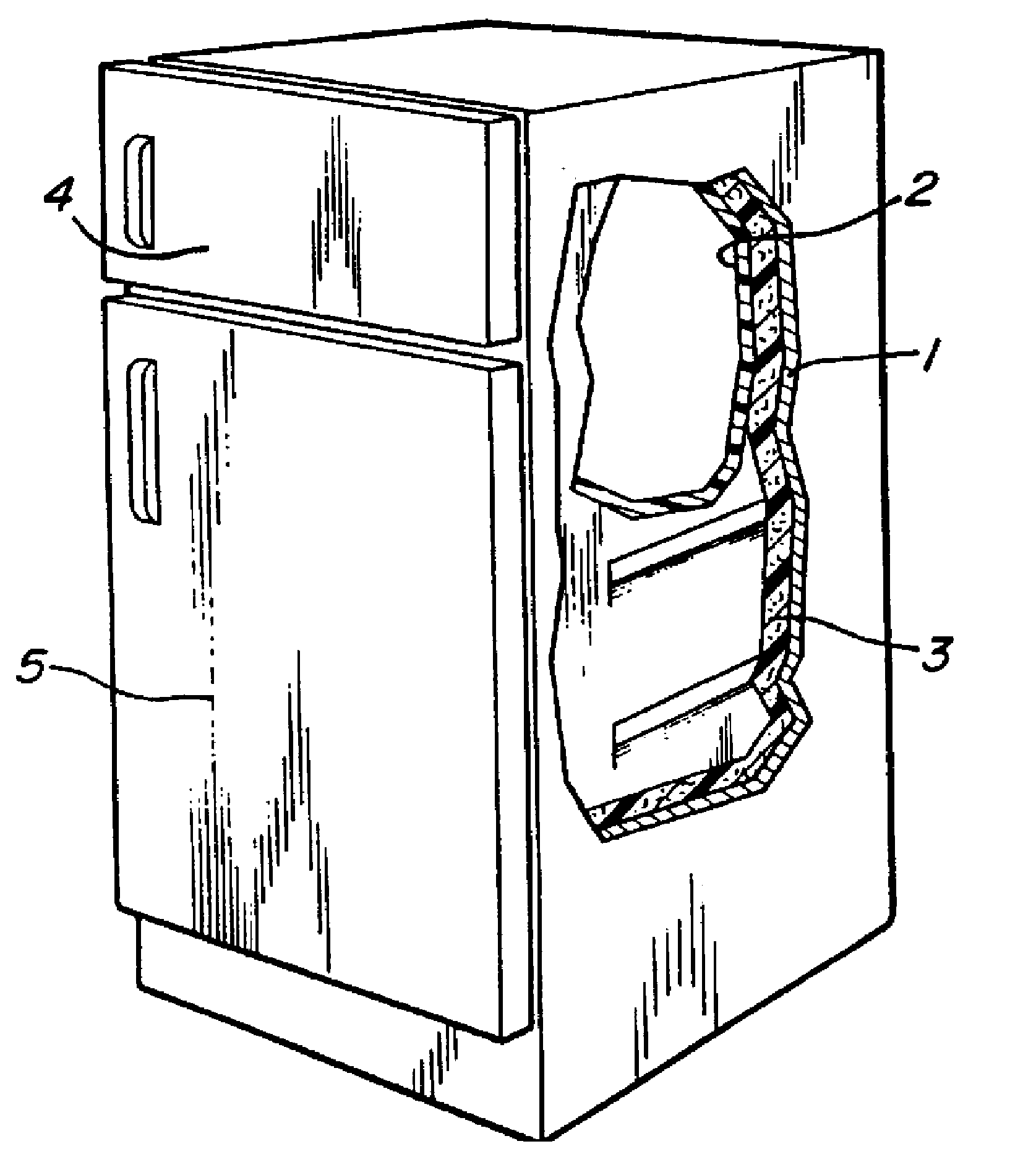

Image

Examples

example 1a

Trans1233ZD / HIPS Liner—10 mm Thickness

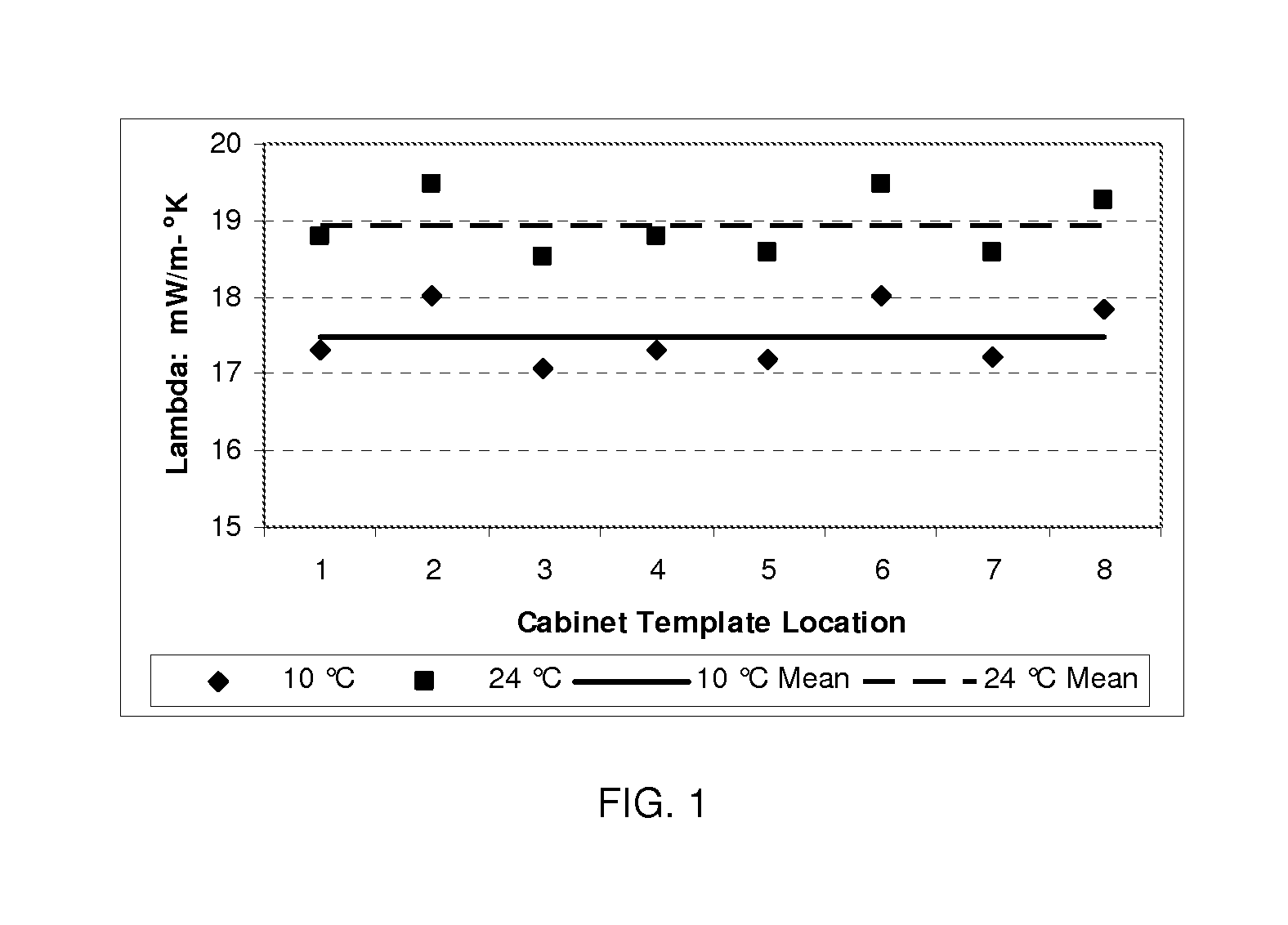

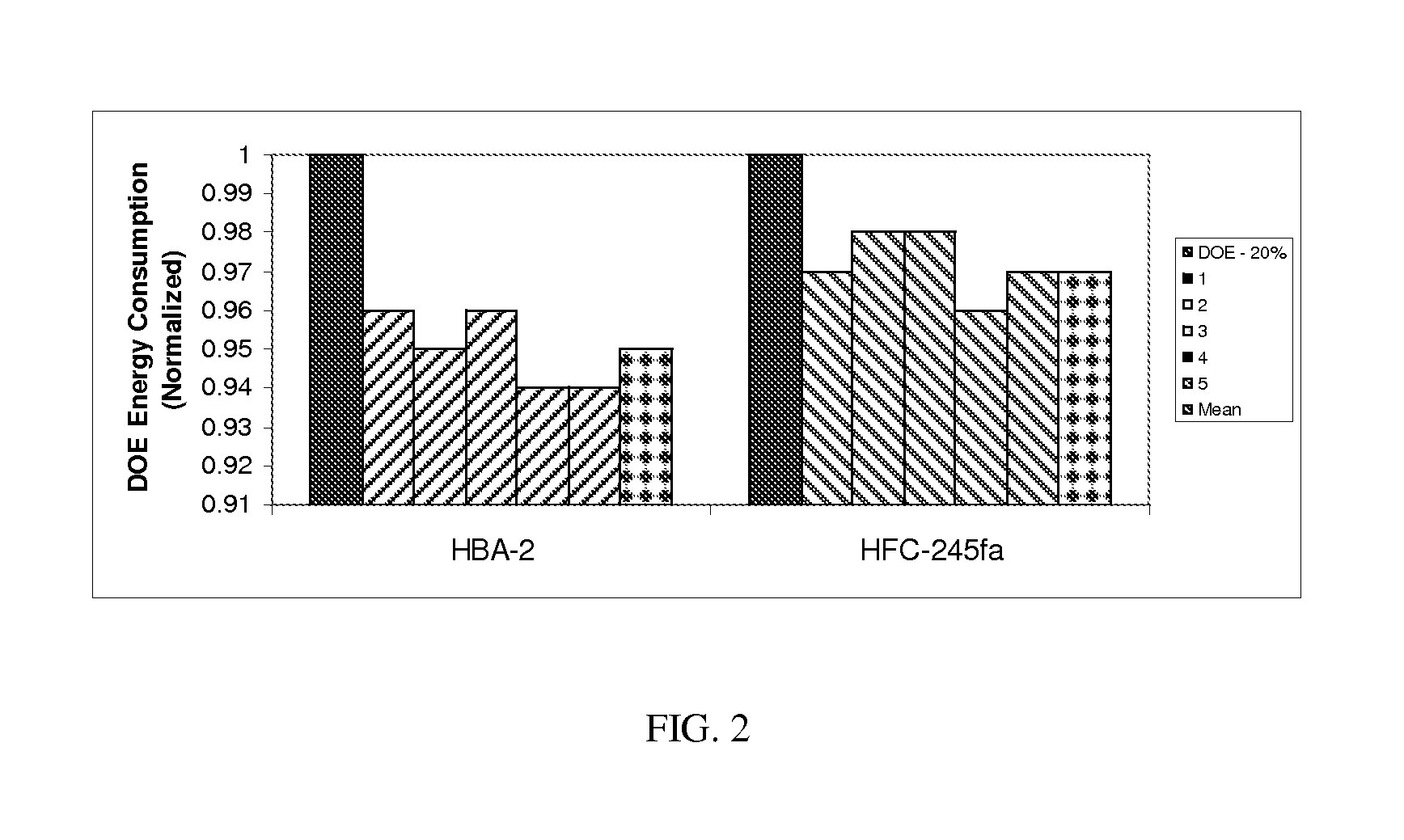

[0061]A scale trial, utilizing 1233zd blowing agent, in a commercially available polyurethane system, in a commercially in available 710 liter (25 ft3) household refrigerator freezer with a food grade and Extrusion and Thermoforming grade HIPS liner having a thickness of 10 mm was undertaken. These thirty two refrigerator cabinets, with associated door sets, were foamed to investigate:[0062]Lambda (k-factor) performance in various locations of the refrigerator;[0063]Liner compatibility;[0064]Dimensional stability;[0065]Freeze stability at target density;[0066]Compressive strength;[0067]Adhesion (plastic liner material and metal case);[0068]Foam closed cell content;[0069]DOE (Department of Energy) Energy Performance;[0070]Energy consumption with 134a refrigerant working fluid; and[0071]Energy consumption with 1234yf refrigerant working fluid.

[0072]The baseline comparison for these low climate change impact refrigerators is the same commercial hou...

example 1b

Trans1233ZD / HIPS Liner—5 mm Thickness

[0099]Example 1A is repeated except that the liner used has a thickness of 5 mm. All results are equivalent, including liner compatibility after the five-day thermal cycling program.

example 1c

Trans1233ZD / HIPS Liner—4 mm Thickness

[0100]Example 1A is repeated except that the liner used has a thickness of 4 mm. All results are equivalent, including liner compatibility after the five-day thermal cycling program.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com