Low-abrasion hydraulic machine

A hydraulic machinery, low-wear technology, applied in mechanical equipment, liquid fuel engines, rotary piston machinery, etc., can solve the problems of easy wear and failure of the inner surface of the stator, affecting product performance and life, and improve reliability and life. The effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

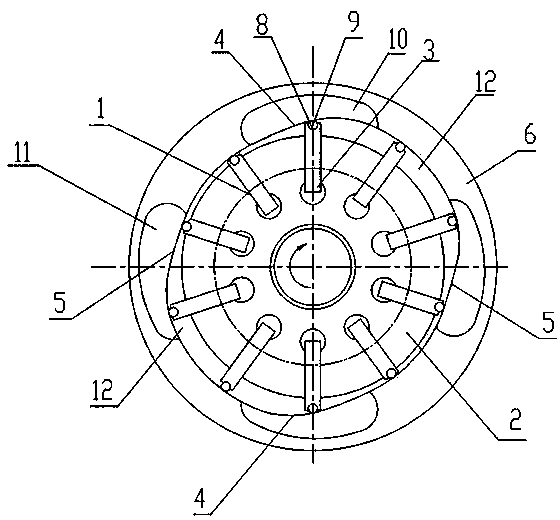

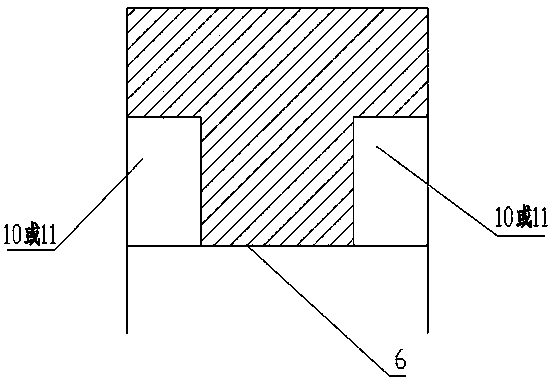

[0035] exist figure 1 In the shown embodiment, a low-wear hydraulic machine comprising a rotor 2 having several radial slots 1, several vanes 3 slidingly arranged in each radial slot 1, arranged outside the rotor 2 and having an inner surface along the circumferential direction A stator 6 with at least one ascending section 4 and at least one descending section 5, side plates 7 arranged at both ends of the stator 6 and the rotor 2, a raceway 8 is provided on the end surface where the outer end of the blade 3 is in contact with the inner surface of the stator 6 , the rolling body 9 is movable in the raceway 8, there is a fluid lubricating film between the rolling body 9 and the raceway 8, the rolling body surface protrudes from the front end of the blade, when the blade slides out, the rolling body surface is in rolling friction contact with the inner surface of the stator, and the stator The ascending section 4 of the inner surface is provided with an inflow window 10, the des...

Embodiment 2

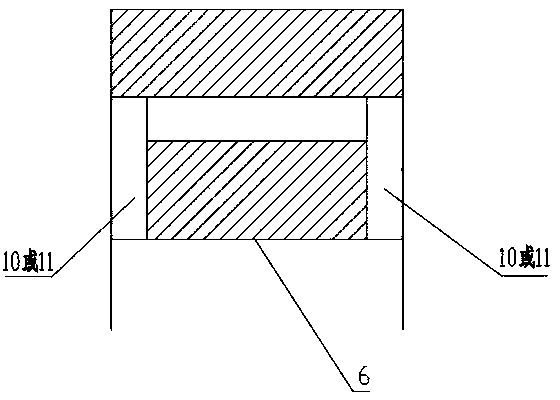

[0039] exist Figure 4 In the shown embodiment, a low-wear hydraulic machine comprising a rotor 2 having several radial slots 1, several vanes 3 slidingly arranged in each radial slot 1, arranged outside the rotor 2 and having an inner surface along the circumferential direction A stator 6 with at least one ascending section 4 and at least one descending section 5, side plates 7 arranged at both ends of the stator 6 and the rotor 2, a raceway 8 is provided on the end surface where the outer end of the blade 3 is in contact with the inner surface of the stator 6 , the rolling body 9 is movable in the raceway 8, there is a fluid lubricating film between the rolling body 9 and the raceway 8, the rolling body surface protrudes from the front end of the blade, when the blade slides out, the rolling body surface is in rolling friction contact with the inner surface of the stator, and the stator The ascending section 4 of the inner surface is provided with an inflow window 10, the de...

Embodiment 3

[0043] exist Figure 5 In the shown embodiment, its technical scheme is basically the same as that of Embodiment 1, the difference is that: the inlet window 10 or the outlet window 11 are provided with three independent ones, and this embodiment is suitable for lower pressure fluid windows. hydraulic machinery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com