Plate composite forming machining equipment based on electromagnetic riveting and friction stir welding

A friction stir and electromagnetic riveting technology, applied in metal processing equipment, metal processing, metal processing machinery parts, etc., can solve the problems of incapable of compound processing according to needs, the plate forming speed and effect are not as good as the electromagnetic riveting forming effect, etc., to improve the stability The effect of improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

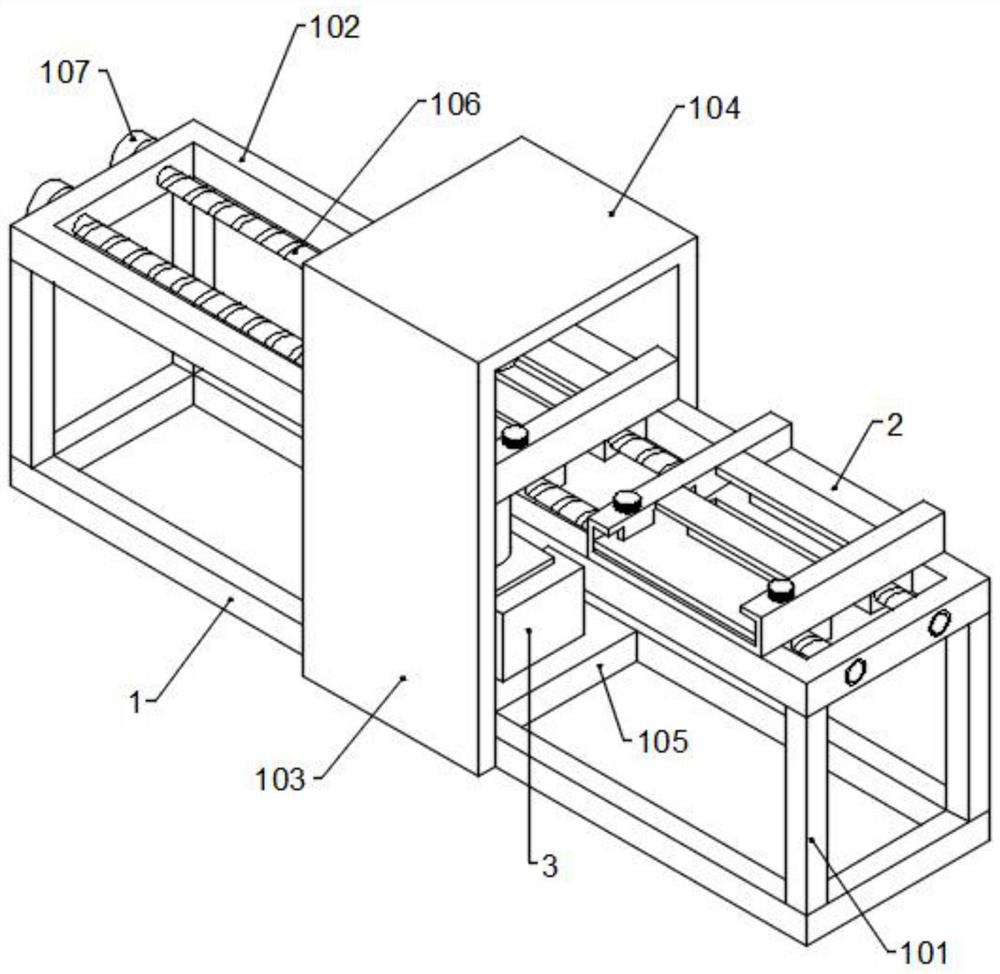

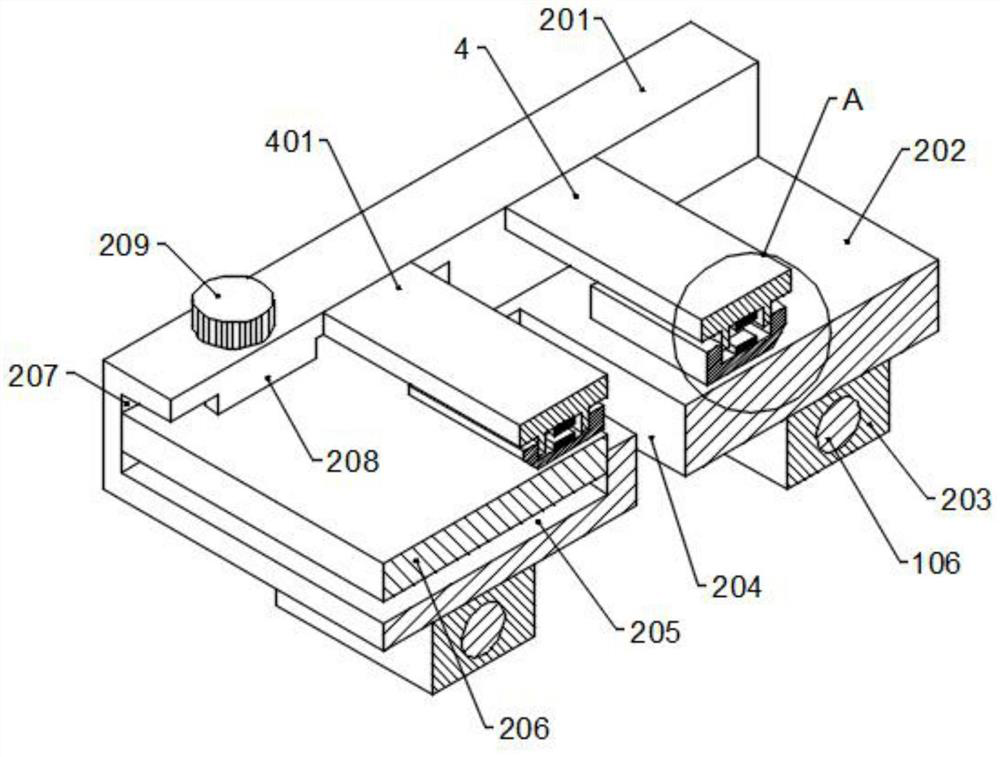

[0050] Please refer to the accompanying drawings, the present invention provides a technical solution: a plate composite forming processing equipment based on electromagnetic riveting and friction stir welding, including a frame and a workbench 102, the frame includes a base 1, and the top surface of the base 1 is evenly fixed There are a plurality of vertical support columns 101, and are fixedly connected to the bottom surface of the workbench 102 through the support columns 101. Two vertical support plates 103 are symmetrically fixed to the middle position of the workbench 102 on both sides of the frame, and the two Mounting seats 105 are fixed between the bottoms of the two support plates 103, and top plates 104 are fixed between the top surfaces. The top faces of the mounting seats 105 are provided with electromagnetic riveting mechanisms 3, and the bottom surfaces of the top plates 104 are provided with stir friction mechanisms, and one of them supports The middle part of ...

Embodiment 2

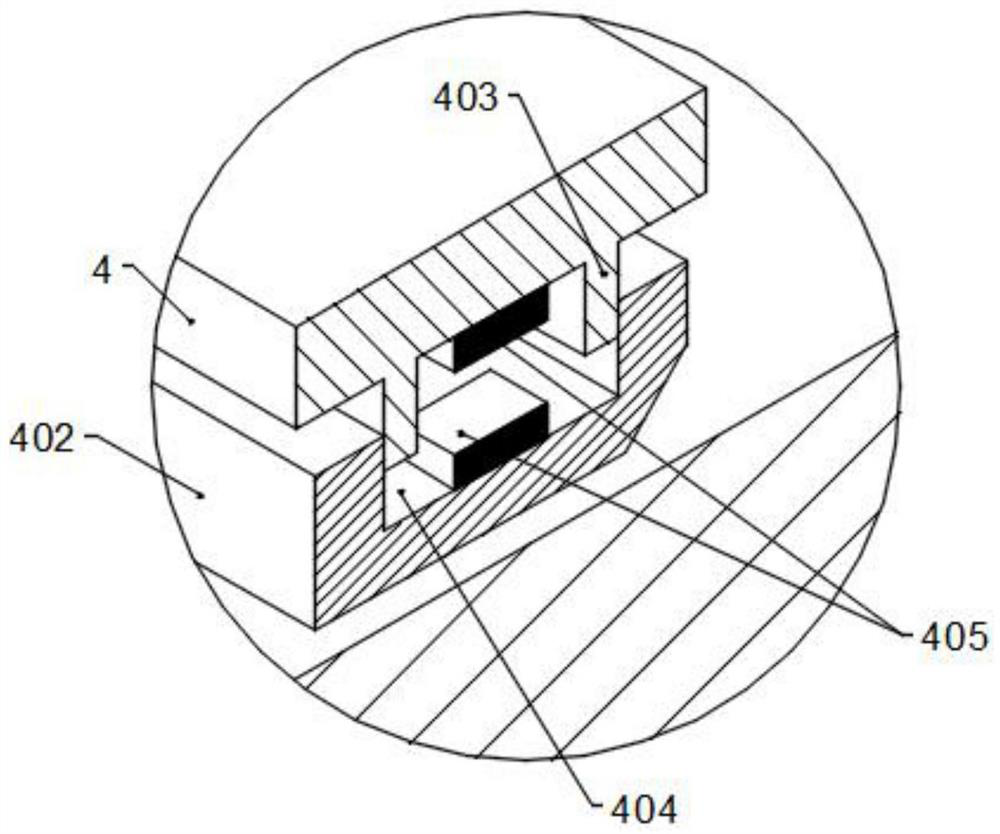

[0076] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the top inner side of the side block 201 is provided with plate grooves corresponding to the two sides of the first positioning plate 4, and the two sides of the first positioning plate 4 are slidably connected to the plate. In the groove, a threaded shaft 407 is respectively fixed in the middle of both sides of the first positioning plate 4, and a horizontal shaft groove is correspondingly provided on the side wall of the plate groove, and the outer end of the threaded shaft 407 protrudes from the shaft groove, and is sleeved with Nut 408.

[0077] The position of the inner side of the plate on the adjustment plate 206 is determined by the inner side of the positioning block 402 below the first positioning plate 4. When the position of the inner side of the plate 206 needs to be adjusted, the nut 408 is loosened and the first position is moved along the direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com