Touch screen and manufacturing method thereof

A manufacturing method and touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve problems such as difficult to implement, difficult to implement touch screen, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

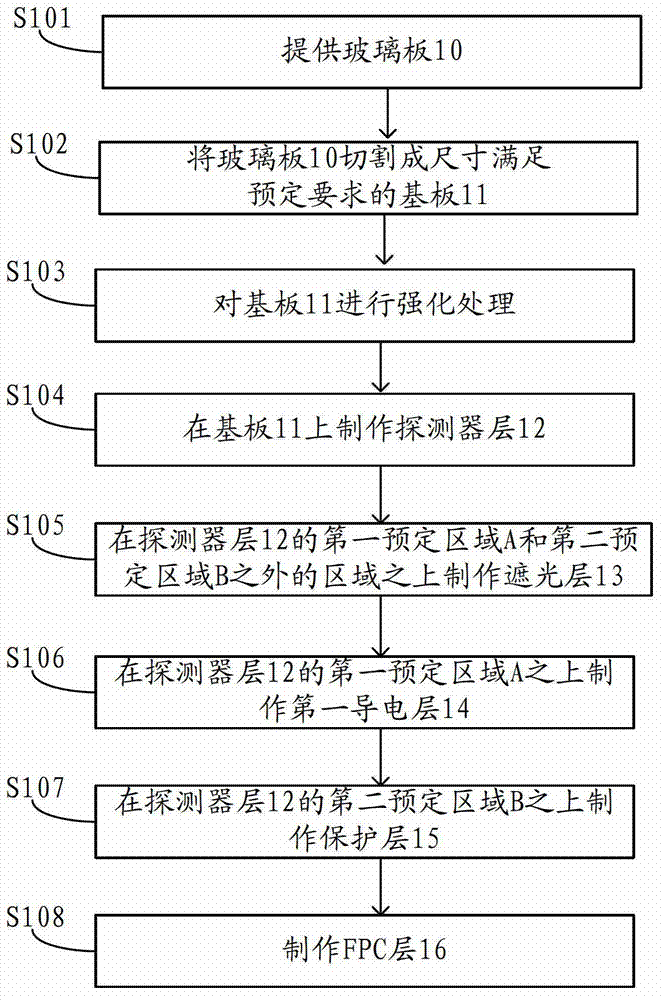

[0065] Embodiment 1 of the present invention provides a method for manufacturing a touch screen, figure 1 A flowchart showing the fabrication method, Figure 2a~2f A schematic structural diagram showing various stages of making a touch screen by using this method, reference together figure 1 and Figure 2a~2f , the production method includes:

[0066] Step S101: providing a glass plate 10, such as Figure 2a shown;

[0067] The glass plate 10 in the embodiment of the present invention generally needs to have higher transparency, lower reflectivity, better thermal stability and corrosion resistance, higher mechanical strength and mechanical processing characteristics.

[0068] The glass plate in the embodiment of the present invention can be glass that can be strengthened, such as borosilicate glass without alkali ions, non-alkali aluminosilicate glass or aluminosilicate glass.

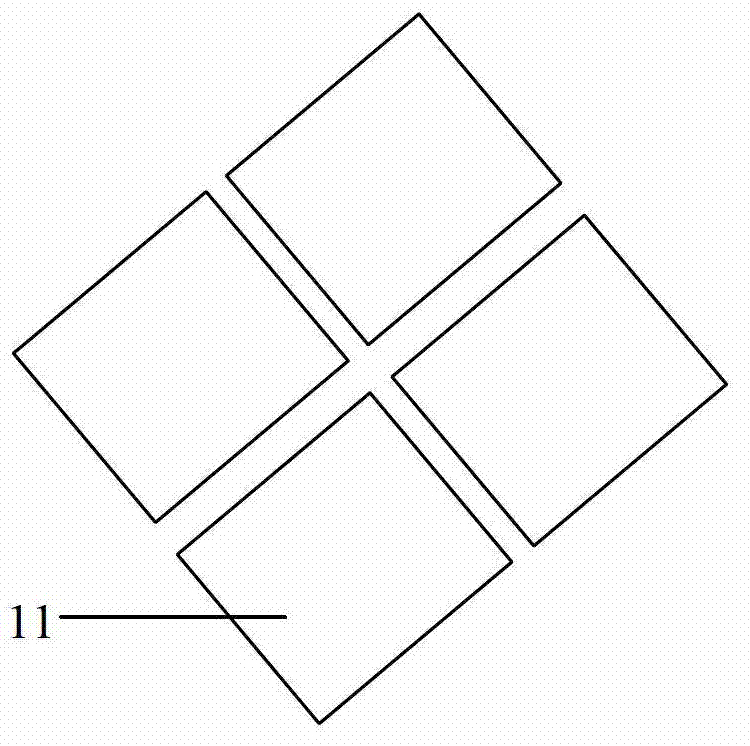

[0069] Step S102: cutting the glass plate 10 into a substrate 11 whose size meets the predeter...

Embodiment 2

[0097] Embodiment 2 of the present invention provides a method for manufacturing a touch screen, Figure 4 A flowchart showing the fabrication method, Figure 5a~5i A schematic structural diagram of various stages of manufacturing a touch screen by using this method is shown. Compared with the first embodiment of the present invention, the detector layer 12 of the touch screen provided by the second embodiment of the present invention has a multi-layer structure. Steps S401 to S403 are the same as Steps S101 to S103 in Embodiment 1. For the structural schematic diagrams of the touch screens at each stage of the manufacturing steps of Steps S403 to S403, see Figure 5a~5c (and Figure 2a~2c Corresponding), for the sake of simplification, the second embodiment of the present invention only introduces the differences from the first embodiment, and the similarities with the first embodiment can be known by referring to the corresponding description in the first embodiment, and wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com