Concrete surface protection treatment method based on plasma hot-spraying technology

A concrete surface and treatment method technology, which is applied in the direction of fusion spraying, metal material coating process, coating, etc., can solve the problems of poor weather resistance, insufficient service life of organic coating materials, and difficulty in infiltrating crystalline materials. Appropriate degree of chemicalization, overcoming insufficient service life, good hardness and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

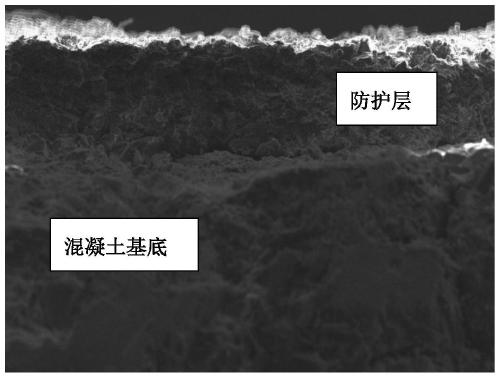

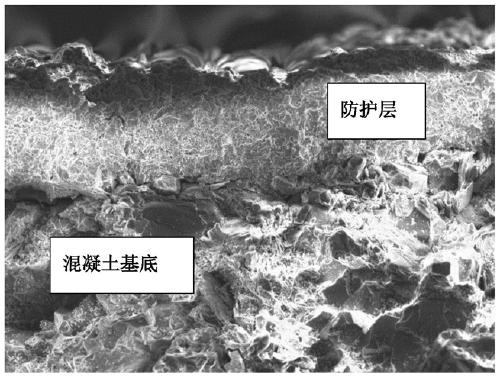

Method used

Image

Examples

Embodiment 1

[0043] Example 1 is aimed at the protection of the exterior wall of a hydropower station at an altitude of 3200m in the Tibet area. It is constructed in winter with a temperature of 5°C and no wind. The concrete strength grade of the exterior wall of the power station building is C35, and the surface is dry and water-free. Adopted the method among the present invention to carry out protective treatment to concrete exterior wall, its treatment process is as follows:

[0044] (1) Use high-pressure air with a temperature of 100°C and a pressure of 0.2 MPa to dry the surface of the concrete exterior wall, control the moving speed of the air nozzle to 0.1m / s, and the distance between the air nozzle and the surface of the concrete exterior wall to 0.15m, until the concrete surface is completely dry;

[0045] (2) After drying, use high-pressure air at room temperature and pressure of 0.35MPa to wrap quartz sand with a particle size of 1.0mm to roughen the surface of the concrete ext...

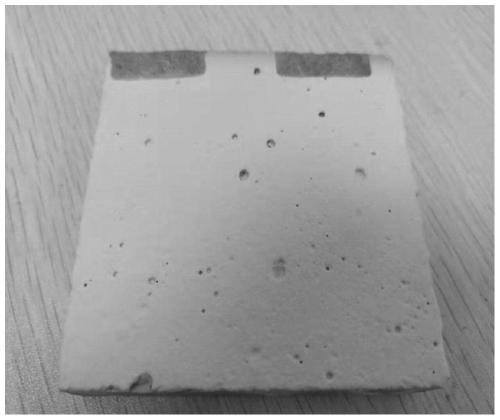

Embodiment 2

[0049] Embodiment 2 is aimed at a certain high-performance concrete slab prefabricated component. The size of the concrete prefabricated component is 600mm×600mm×63mm, the concrete strength grade is C60, and the construction environment is indoor spraying. The specific treatment process is as follows:

[0050] (1) Use high-pressure air with a temperature of 80°C and a pressure of 0.25 MPa to dry the surface of the concrete prefabricated part, control the moving speed of the air nozzle to 0.3m / s, and the distance between the air nozzle and the surface of the concrete prefabricated part is 0.08m, until the concrete surface is completely dry;

[0051] (2) After drying, the surface of the concrete prefabricated part is roughened by using high-pressure air with a normal temperature and a pressure of 0.4 MPa to carry quartz sand with a particle size of 0.5 mm, and the distance between the quartz sand nozzle and the surface of the concrete prefabricated part is kept at 0.6m, control ...

Embodiment 3

[0057] Example 3 is aimed at the protection of the concrete face of a rockfill dam of a water conservancy project at an altitude of 1300m in Xinjiang. It is constructed in summer with a temperature of 35°C and a breeze. The concrete strength grade of the panel is C30, and the surface is dry and anhydrous. The specific process is as follows:

[0058] (1) Use high-pressure air with a temperature of 100°C and a pressure of 0.3MPa to dry the surface of the concrete panel, control the moving speed of the air nozzle to 0.2m / s, and the distance between the air nozzle and the concrete surface to be 0.12m until the concrete surface completely dry;

[0059] (2) After drying, use high-pressure air at room temperature and a pressure of 0.3MPa to carry quartz sand with a particle size of 0.8mm to roughen the surface of the concrete panel, and keep the distance between the quartz sand nozzle and the concrete surface at 0.5m. Control the moving speed of the quartz sand nozzle to 0.15m / s, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com