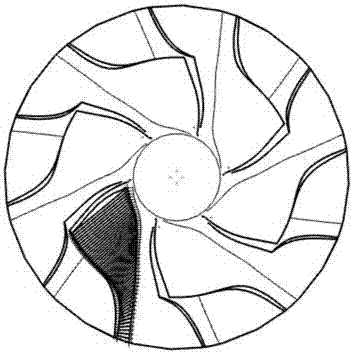

Process method for reducing impeller blade side milling machining deformation errors

An impeller blade, processing deformation technology, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems affecting the quality, efficiency, precision and surface quality of impeller blade processing, blade deformation, error increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

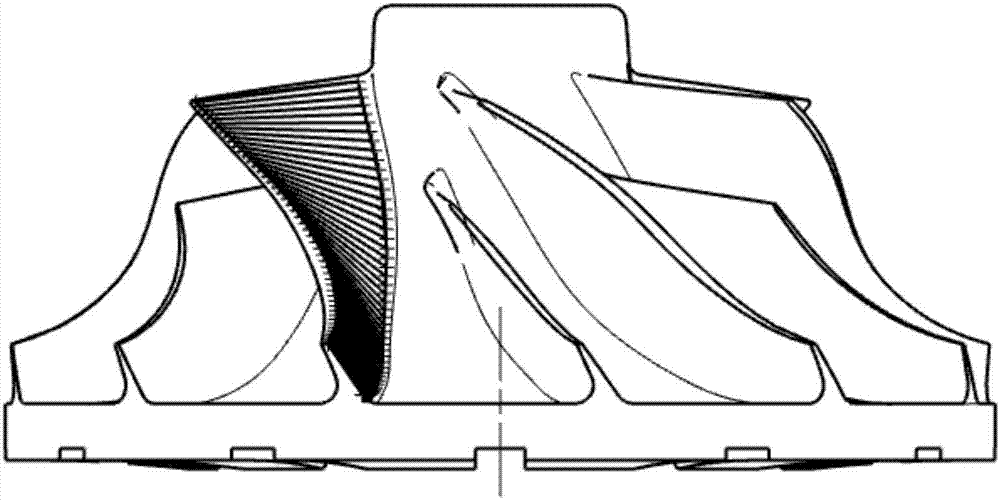

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] A process method for reducing the deformation error of impeller blade side milling, the specific steps are:

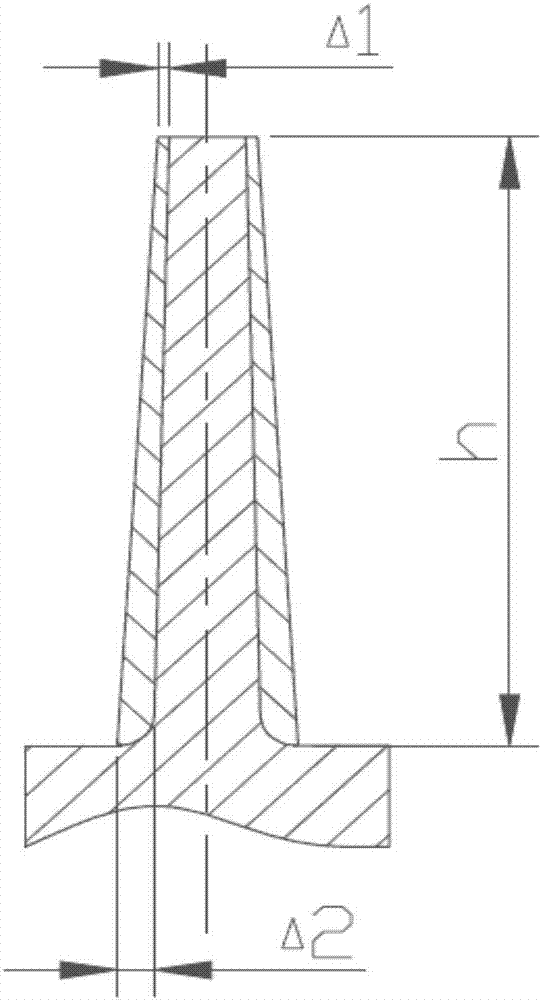

[0019] Step 1: Reserve a rough machining allowance

[0020] According to the roughly linear relationship between the deformation of each point on each impeller blade during the machining process, the cutting force and the cutting depth, it is determined that the rough machining allowance reserved for the impeller blade is the thickest at the blade root and the thinnest at the blade crown. And reserve Δ for the rough machining allowance of the blade according to S;

[0021] S(h / a) Leaf crown margin reserve Δ 1

Leaf root allowance reserved Δ 2

15≤S<20

0.05mm 0.15~0.40mm 20≤S<25

0.05mm 0.35~0.90mm 25≤S<30

0.05mm 0.84~1.25mm 30≤S<35

0.05mm 0.67~1.78mm

[0022] Where h is the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com