A kind of clamping method of compressor blade and used clamp

A compressor and clamping technology, which is applied in clamping, manufacturing tools, positioning devices, etc., can solve the problems of increasing friction coefficient, leaving blank traces, and large processing deformation, so as to reduce waste loss and improve surface quality , Reduce the effect of processing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

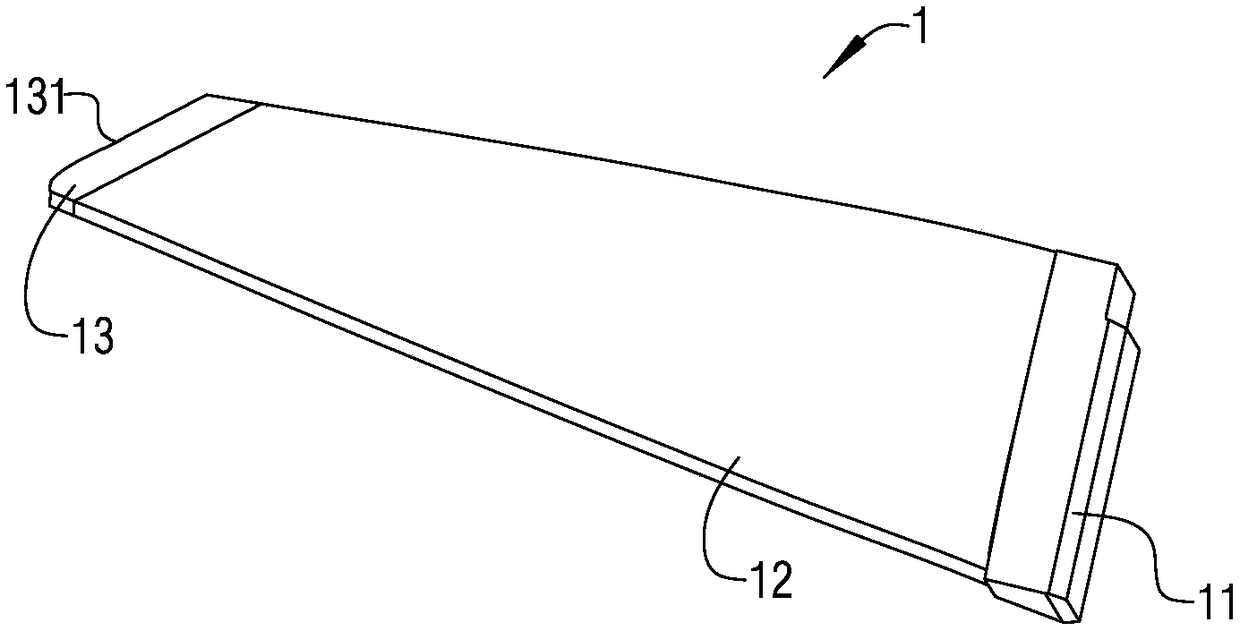

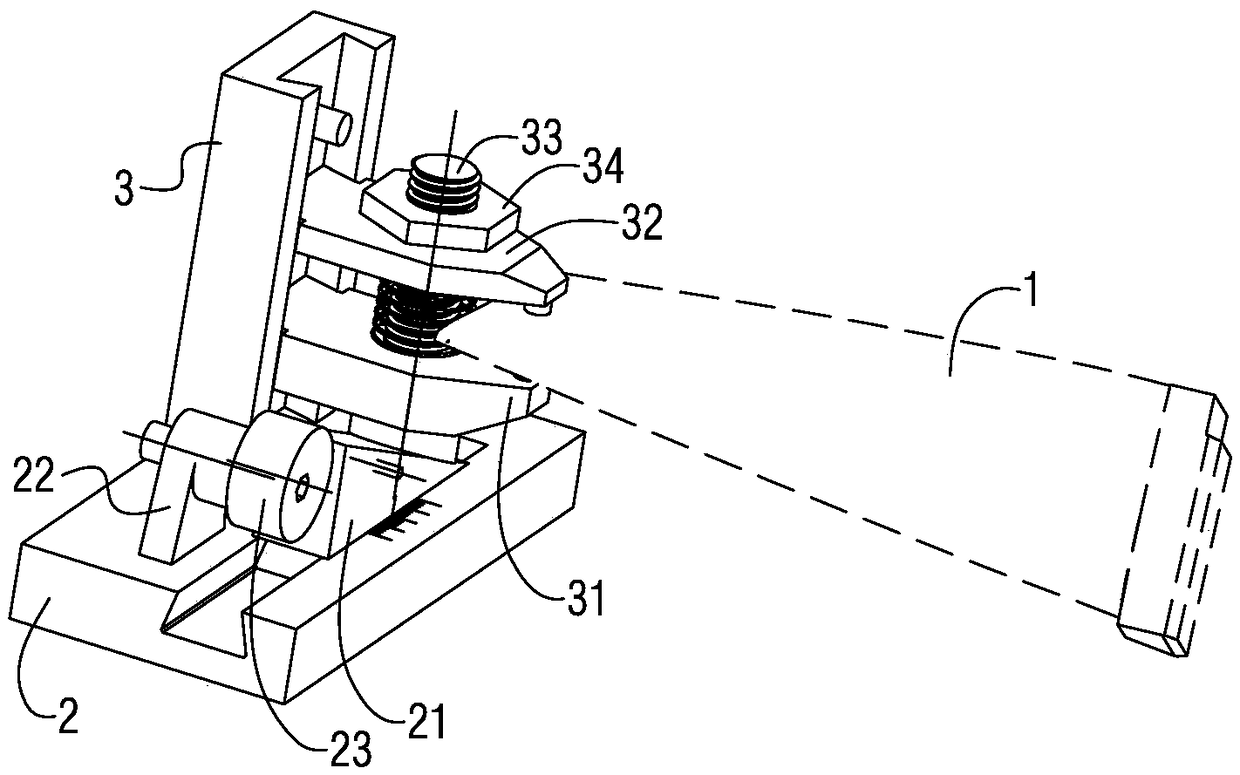

[0020] figure 1 It is a structural schematic diagram of a blank of a compressor blade; figure 2 It is a schematic structural principle diagram of a clamp used in a compressor blade clamping method according to a specific embodiment of the present invention. see figure 1 , figure 2 As shown, the present invention provides a method for clamping a compressor blade, which is used for clamping a blank 1 of a compressor blade. The blank 1 is a forging, including a tenon portion 11 and an airfoil portion 12 and the tip portion 13, which comprises the steps of,

[0021] Step A, during the forging forming process, ensure that the length of the blade tip 13 is 6-8mm;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com