Method and device for regulating the vacuum supply of calibration tools

A tool and vacuum technology, which is applied in the field of adjusting the vacuum supply of calibration tools, can solve the problem of high energy consumption and achieve the effect of improving the quality of profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

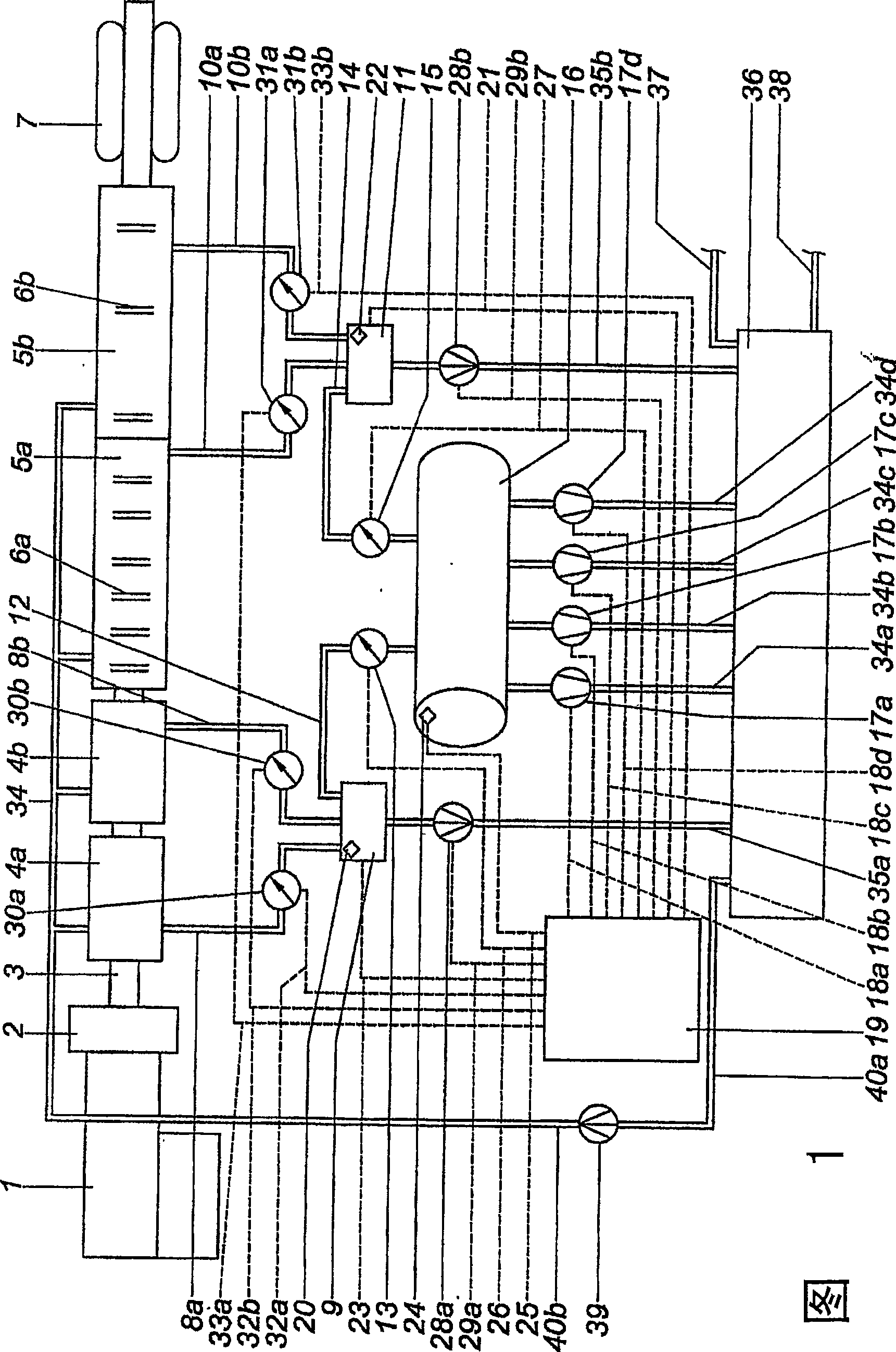

[0015] The extrusion line in the figure comprises an extruder 1 with an extrusion nozzle 2 for producing plastic profiles 3 . The plastic profile 3 is cooled and calibrated in the first dry calibration tool 4a. Downstream of the first dry calibration tool 4a, the next dry calibration tool 4b is arranged, and the calibration tank 5a with a plurality of light shields 6 is connected to the downstream side of the dry calibration tool 4b, and if necessary, flows to other calibration tanks , such as the next calibration slot 5b in the illustrated embodiment. The schematically depicted caterpillar vents 7 are used to provide the necessary tension on the profile 3 .

[0016] The dry calibration tools 4a, 4b are connected to the first condenser 9 via vacuum conduits 8a, 8b. In the same way, the calibration tanks 5a, 5b are connected to the second condenser 11 via vacuum conduits 10a, 10b. In this case, the condensers 9 , 11 are used to separate entrained coolant together with the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com