Forming tool for composite fan blade laying layer units

A technology for forming tooling and fan blades, which is applied in the field of composite material manufacturing, can solve the problems of complex forming process, long lay-up cycle, and high precision requirements for parts with varying thickness from tenon to blade tip, so as to improve surface quality and shorten operation Time, the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

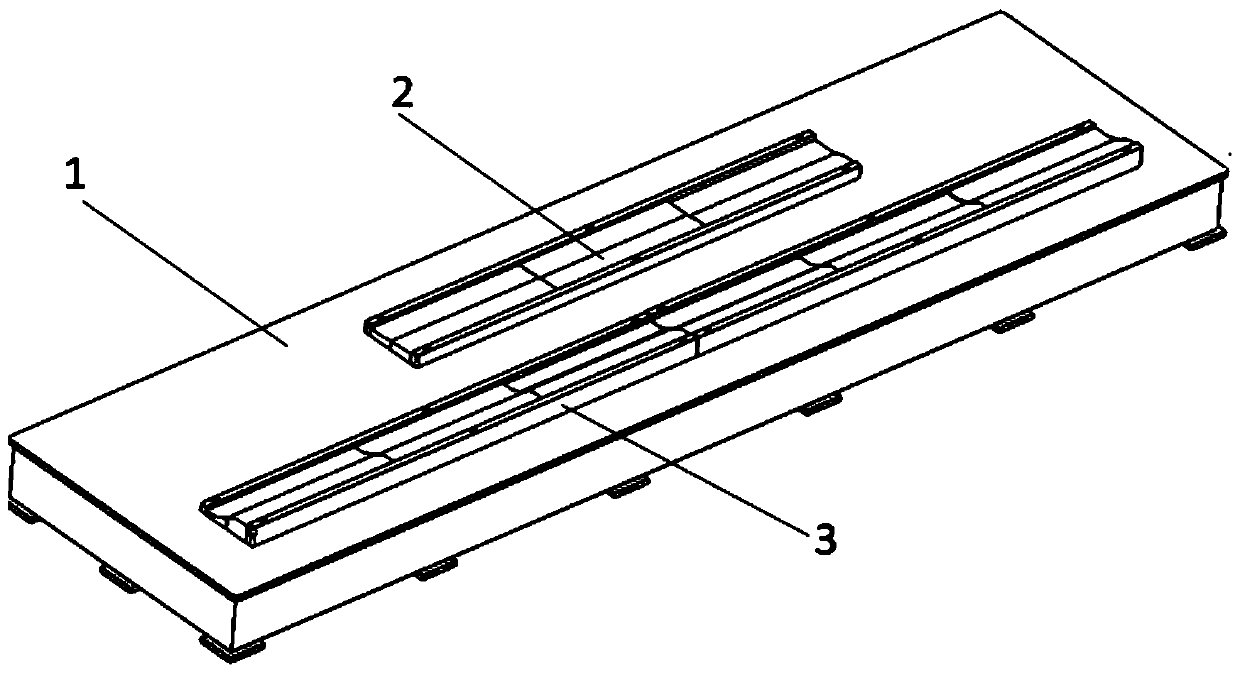

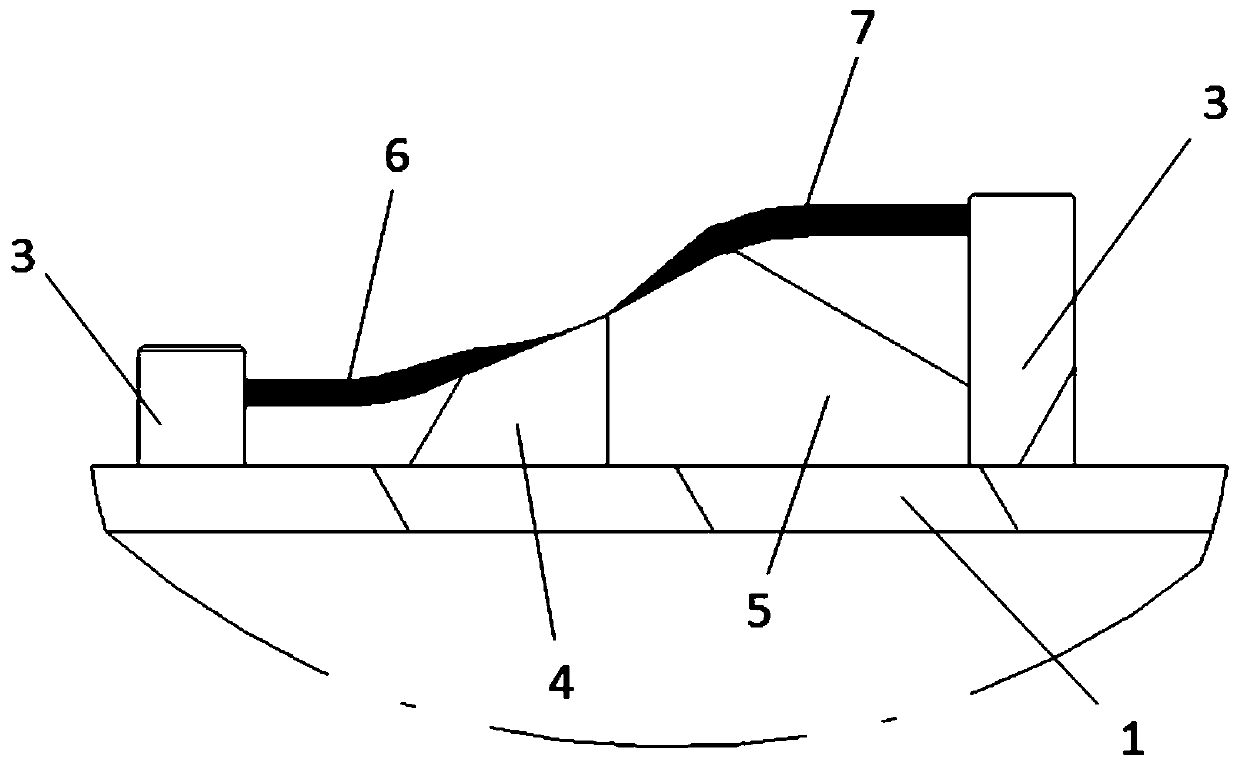

[0024] See attached figure 1 , 2 As shown, the molding tooling of this kind of composite fan blade layup unit includes a layup platform 1 and a layup working surface 2 arranged on the layup platform 1, and layup datums are set on both sides of the layup working surface 2 Block 3 is used as a lay-up reference, and the number of lay-up working surfaces 2 is the same as the number of lay-up units in the tenon of the composite fan blade.

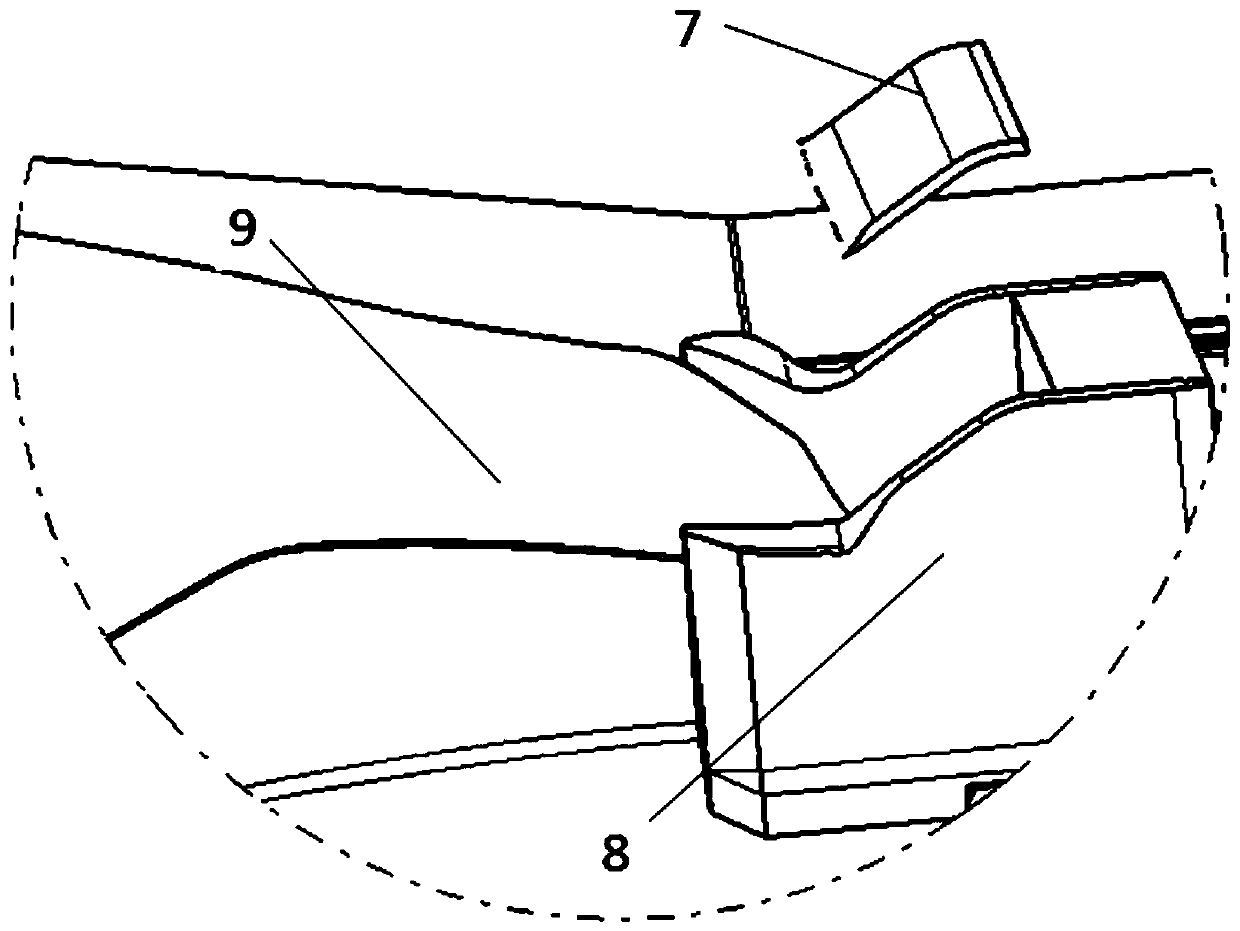

[0025] In this embodiment, the shape of the lay-up working surface 2 is center-symmetrical, and the two sides of the center point are the concave working surface 4 and the convex working surface 5 respectively, and the concave working surface 4 is used for the suction of the tenon of the composite fan blade. The suction surface layer unit body 6 on the surface side, the convex working surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com