Absorbable bone plate profiling shaping structure and method thereof

A bone plate and mounting plate technology, applied in the direction of outer plate, fixer, internal bone synthesis, etc., can solve the problems affecting the strength and life of absorbable bone plates, affecting the quality of life of patients with normal rehabilitation of fracture sites, etc., to improve profiling and stereotypes Effect of quality, improving strength and life, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

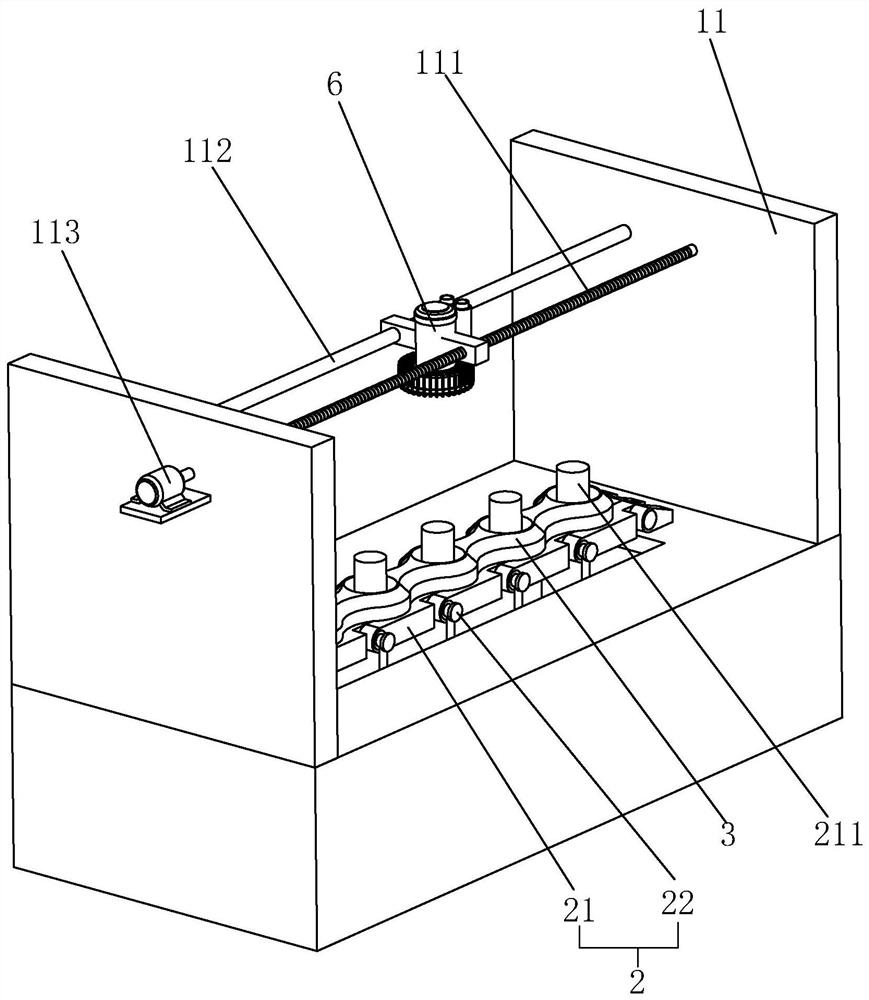

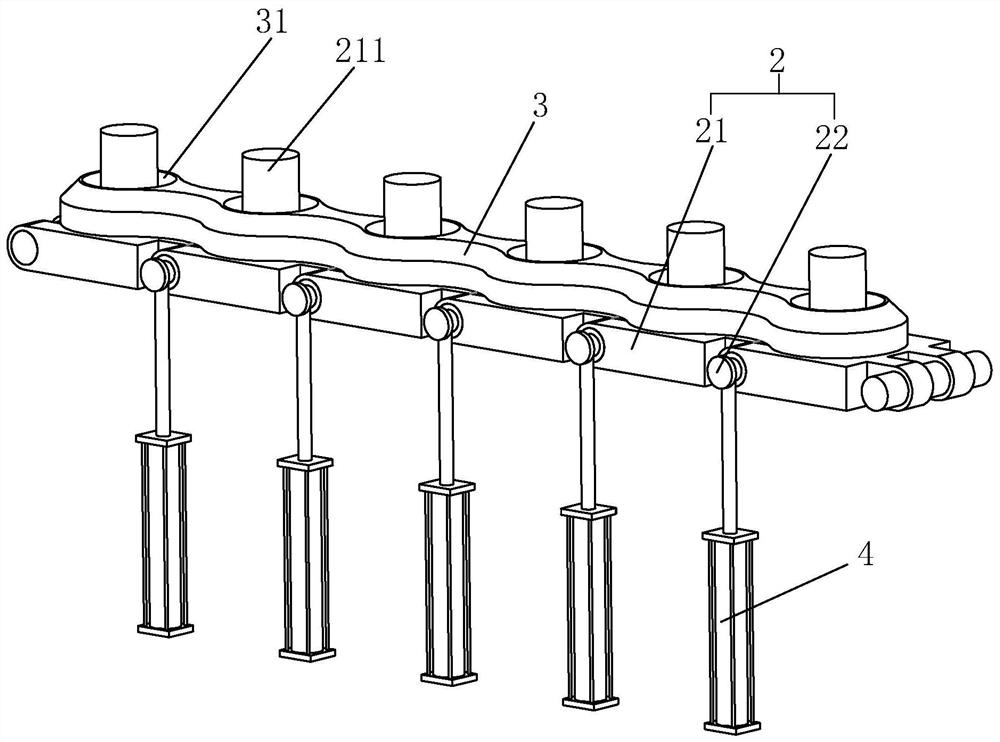

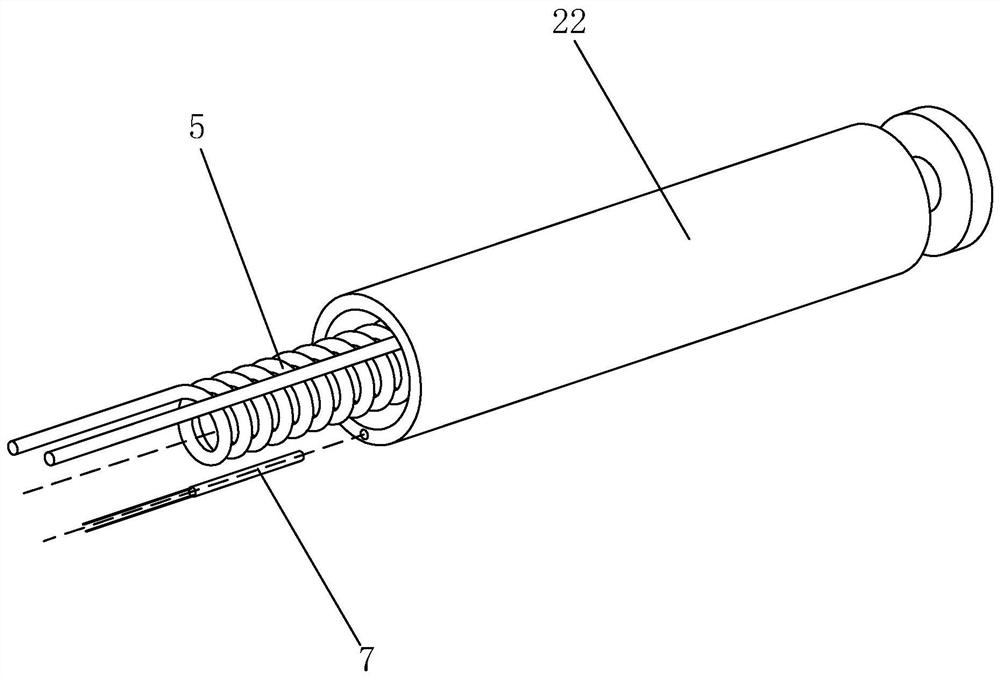

[0044] An absorbable bone plate profiling structure, such as figure 1 As shown, it includes a frame 1, the upper surface of the frame 1 is provided with a bone plate fixing jig 2, the bone plate fixing jig 2 includes a connecting shaft 22 and a plurality of clamp joint units 21, every two adjacent clamp joint units 21 pass through The connecting shaft 22 is hingedly connected, and the two clamp joint units 21 at both ends of the bone plate fixing clamp 2 are hingedly connected to the upper surface of the frame 1, and a plurality of driving parts 4 are fixedly arranged inside the frame 1, and the plurality of driving parts 4 are connected with the connecting shaft. 22 are in one-to-one correspondence and are used to drive the connecting shaft 22 to rise, thereby driving the adjacent two clamp joint units 21 to be arched upward to form a bent shape, and the upper surface of the bone plate fixing clamp 2 is relatively fixed with an absorbable bone plate body 3 , a heating device ...

Embodiment 2

[0052] A method for profiling and shaping an absorbable bone plate, comprising the following steps:

[0053] S1. Align the clamping hole 31 of the absorbable bone plate body 3 with the clamping shaft 211, and place the absorbable bone plate body 3 on the bone plate fixing fixture 2 horizontally;

[0054] S2. Make the designated driver 4 drive the connecting shaft 22 to move upward, thereby driving the two clamp joint units 21 correspondingly connected to the connecting shaft 22 to form a certain angle, and the angle measuring sensor 8 detects the included angle between the two clamp joint units 21, and When the included angle reaches the specified angle, the driving member 4 stops moving;

[0055] S3, the infrared heating device corresponding to the connecting shaft 22 that moves upward is activated to provide heat for the profiling deformation position of the absorbable bone plate body 3, and the temperature is kept at 80-160 degrees Celsius, and the heating time is 10 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com