Hot drawing-air bulking composite forming method for high-temperature titanium alloy skin

A high-temperature titanium alloy, composite forming technology, used in forming tools, metal processing equipment, transportation and packaging, etc., can solve problems such as poor forming quality, and achieve improved part profile quality, low loss, and avoidance of wrinkling and cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A specific embodiment of the present invention discloses a high-temperature titanium alloy skin hot-drawing air-expansion composite forming method, such as Figure 4 As shown, it is the formed high-temperature titanium alloy skin part 8, the material is Ti60, and it is the skin of the air intake of the aircraft. Large, the two ends of the conventional skin thermoforming are prone to wrinkles, and the wrinkles are usually cut off to repair the patch.

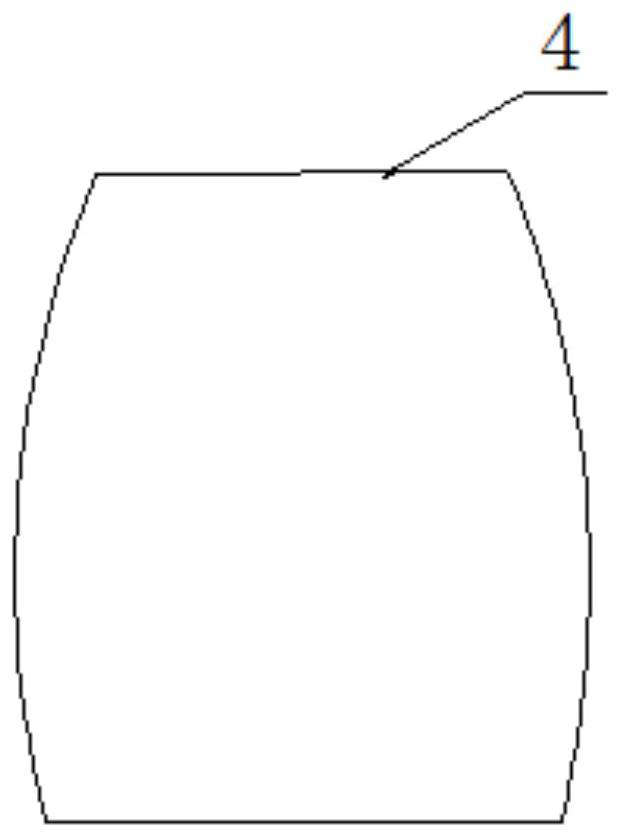

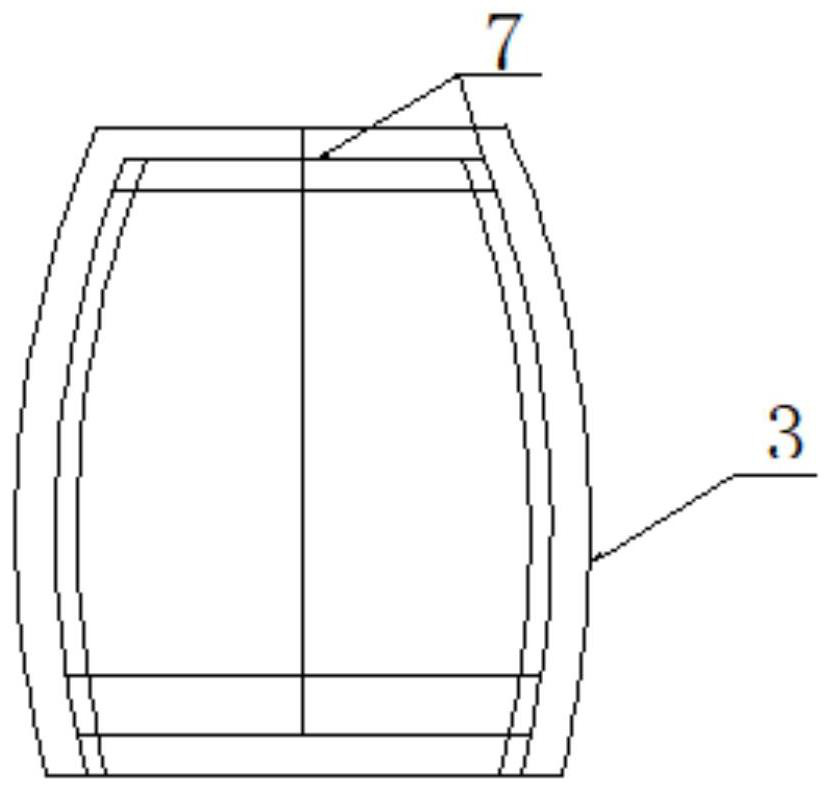

[0072] Such as Figure 2-Figure 3 As shown, it is the formed part blank 4 and the process plate 3, and the process plate 3 has an air passage 7.

[0073] Specific steps include:

[0074] Step S1: Convex-concave mold structure design.

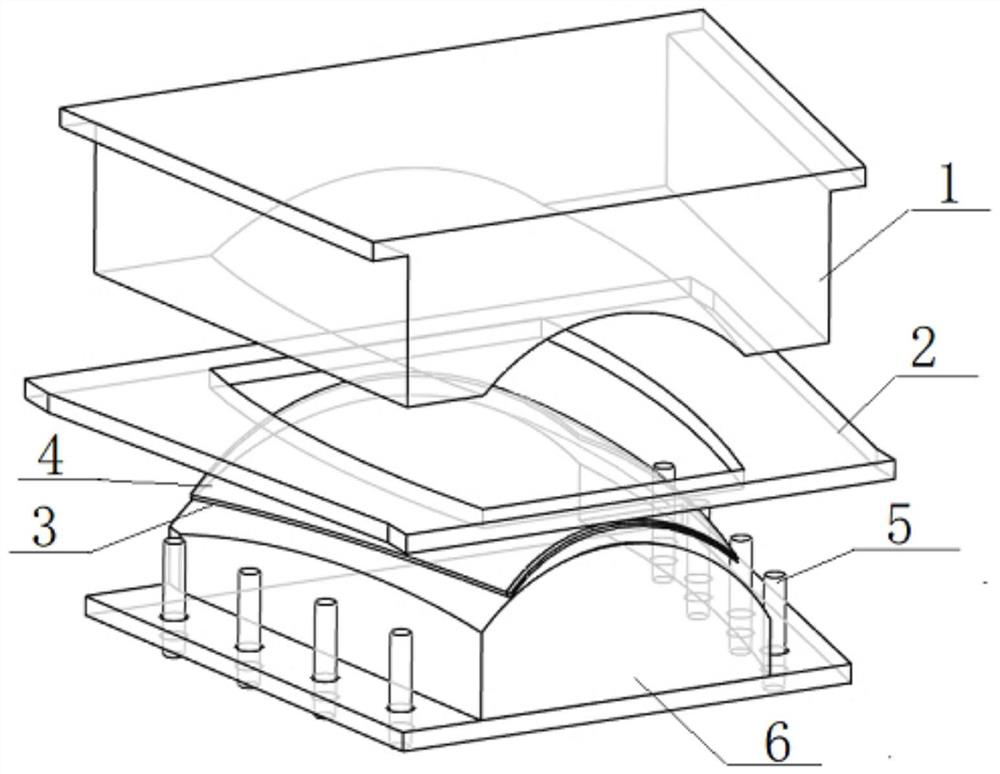

[0075] Convex mold structure such as figure 1 shown. It specifically includes die 1, blank holder 2, process plate 3 and punch 6, binder ring 2 is set between die 1 and punch 6, process plate 3 is set between punch 6 and press ring 2 , the die 1 is located above the punch 6 . The mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com