Copper bar roller alignment device for motor rotor coil edgewise-winding machine

A technology for motor rotors and rollers, which is used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of wasting copper materials, coil appearance and shape, wrinkling and waviness of magnetic pole coils, etc., to improve the surface The effect of waviness, expansion of working range and improvement of profile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

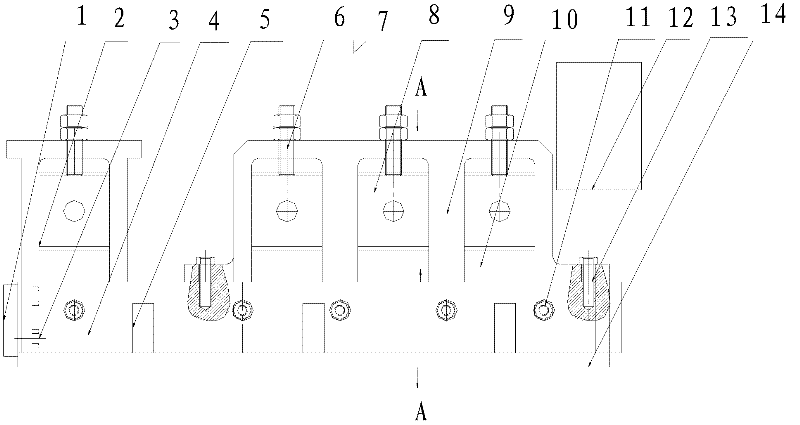

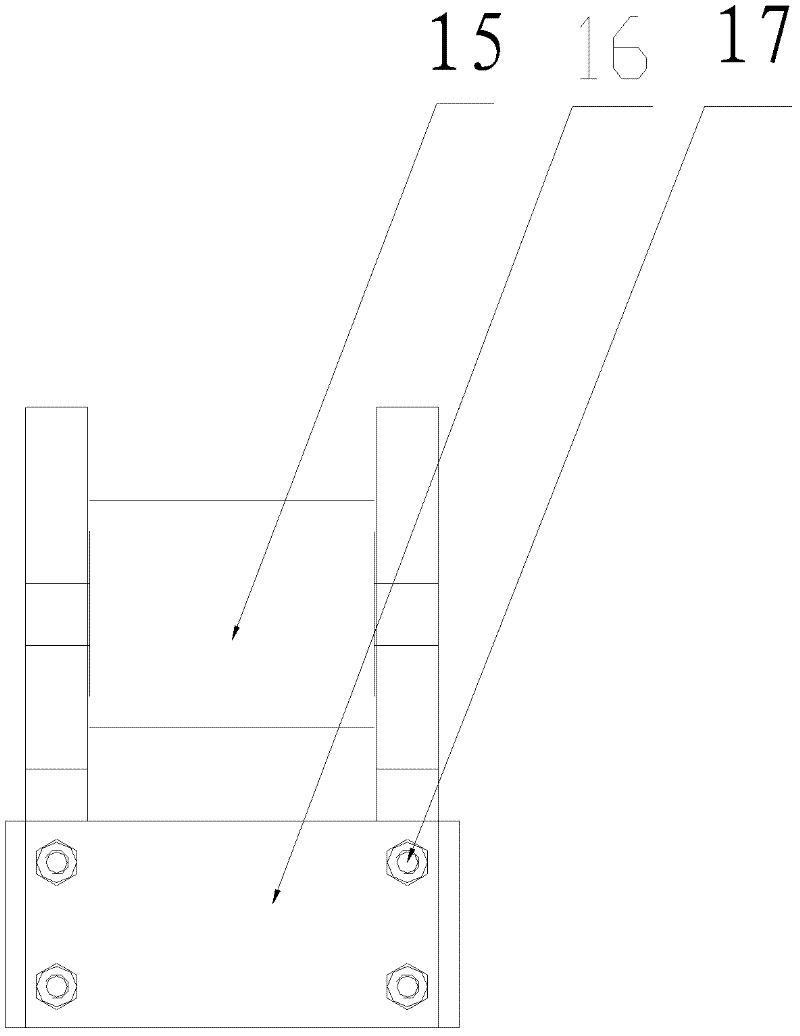

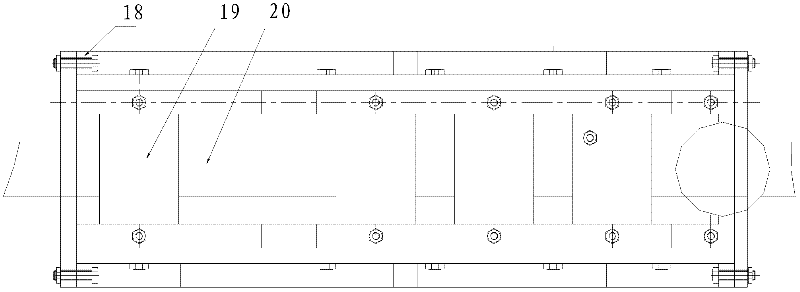

[0021] A copper row roller straightening device for a motor rotor coil flat winding machine, including a bottom plate, a baffle plate, a single support, a combined support, a side pressure plate, a positioning plate, a support plate, a floating pressure block and a roller shaft, and a single support The seat and combined support are equipped with adjustable notches and floating pressure blocks. The floating pressure blocks are equipped with rolling bearings and connected with the roller shaft. The single support and combined support are fastened to the working platform by bolts. Side pressure plates are fastened together with bolts, baffle plates, positioning plates and support plates are arranged at the left and right ends, and the baffle plates, positioning plates and support plates are fastened together with bolts.

[0022] There are threaded holes on the single support and combined support, and there are double-ended screws through the threaded holes to tighten with the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com