Process for strengthening milling rigidity of aluminum-alloy ultrathin-blade integral impeller

A technology of integral impeller and process method, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems affecting the quality and performance stability of impeller and impeller components, undercut and overcut of blade surface contour, and missing blade. , to achieve the effect of improving profile quality, reducing vibration and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

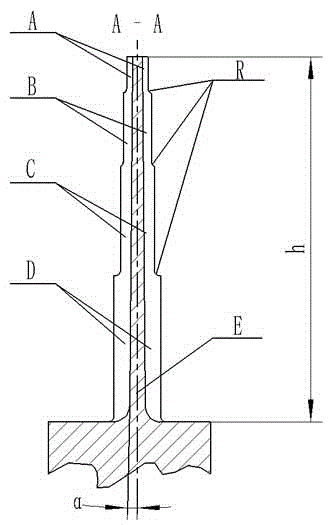

[0023] The present invention will be further described below based on the drawings.

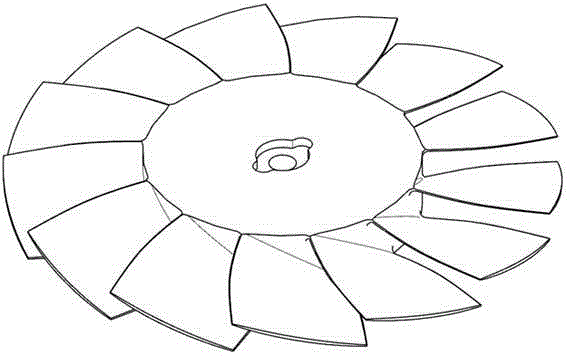

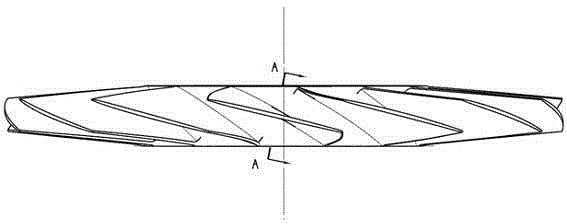

[0024] A process method for enhancing the milling rigidity of an aluminum alloy material ultra-thin blade integral impeller includes the following steps:

[0025] Step 1: Layer the leaves.

[0026] The layering scheme is shown in Table 1.

[0027] Table 1: Leaf layering scheme. Where h is the height of the leaf, a is the average thickness of the thickest part of the leaf crown and root, and ε is the ratio of the leaf height to the average thickness.

[0028]

[0029] Step 2: Reserve the rough machining allowance.

[0030] The rough machining allowances are reserved for each layer respectively, and the reserved plan is shown in Table 2.

[0031] Table 2: The reserve plan for each layer of rough machining blade

[0032]

[0033] Step 3: Five-axis linkage finishing.

[0034] Use ball-end milling cutter to perform 5-axis linkage finishing of ultra-thin blade integral impeller. For the different margins reser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com