Camera lens module with optical anti-vibration function

A lens module, optical anti-shake technology, applied in cameras, optics, optical components, etc., can solve the problems of low productivity, increased frequency characteristic deviation, difficult operation, etc., to improve assembly and reduce assembly defect rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the optical image stabilization camera lens module according to the embodiment of the present invention will be described in detail with reference to the attached figures. The terms used in this specification are used to accurately represent the embodiments of the present invention, and may vary with the understanding of users or operators, and may be different from the common practice in the field to which the present invention belongs. Therefore, half of the content of this specification is used for the definition of the term.

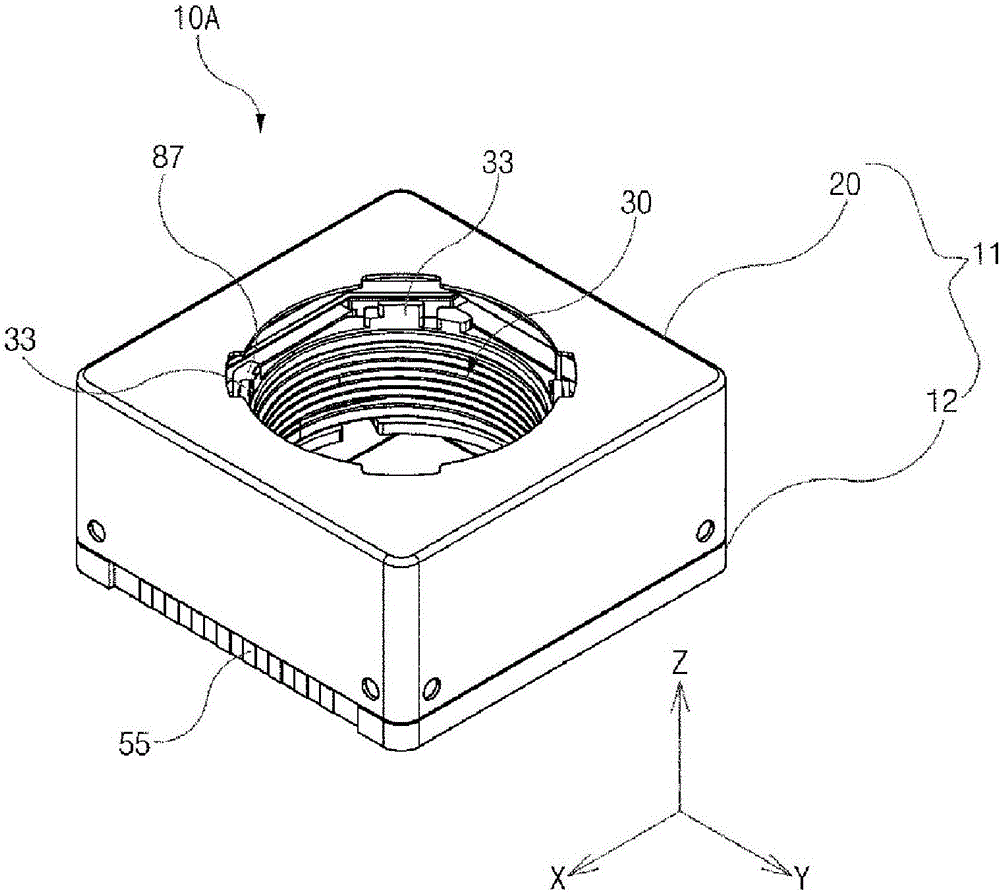

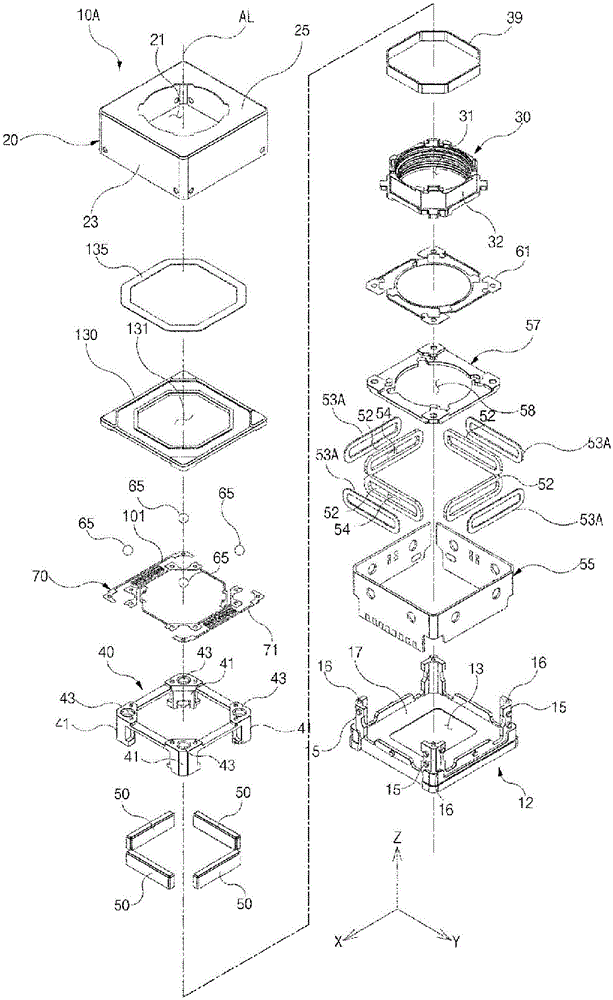

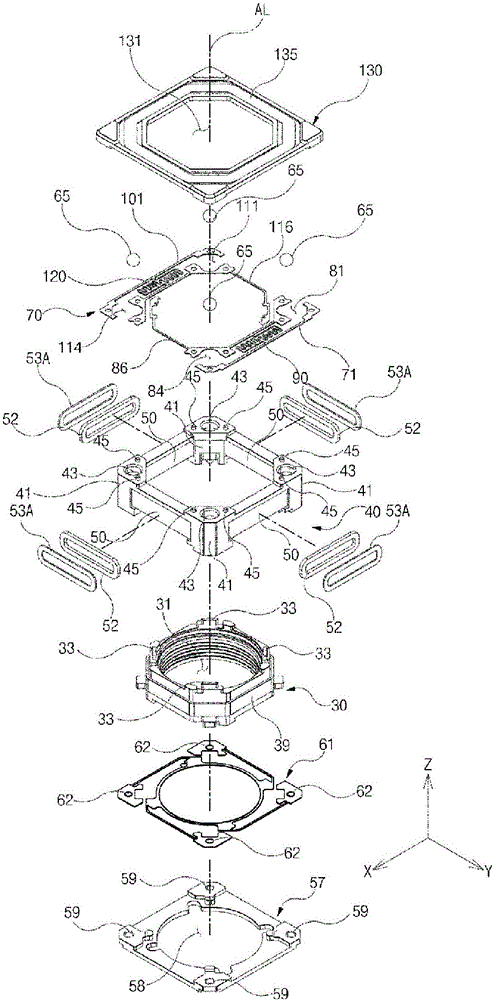

[0032] figure 1 It is a perspective view illustrating a camera lens module in an embodiment of the present invention. figure 2 It is an exploded perspective view illustrating a camera lens module in an embodiment of the present invention. image 3 and Figure 4 yes figure 2 Partially enlarged exploded perspective view, image 3 An illustration of the scene viewed from above, Figure 4 It is an illustration drawing of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com