Fluid variable damping shock absorber and washing machine equipped with same

A shock absorber and variable damping technology, which is applied to shock absorbers, other washing machines, liquid shock absorbers, etc., can solve problems such as inability to absorb shocks, damping force not too large, and increased boost vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

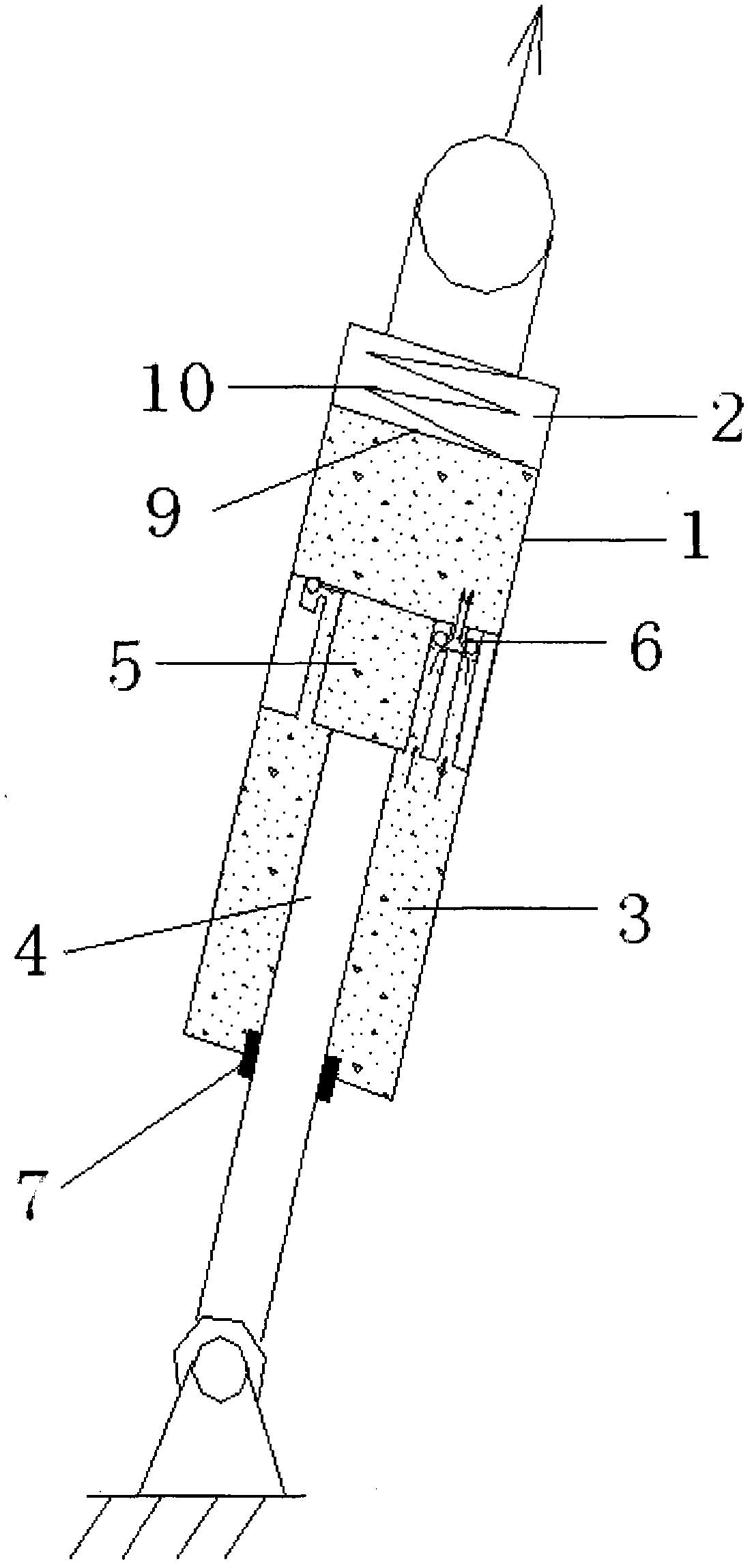

[0052] Such as figure 2 The shown fluid variable damping shock absorber includes: a shock absorber cylinder 1 composed of a damping chamber 3 and a buffer chamber 2; a piston rod 4 inserted into the cylinder 1; a piston rod fixedly arranged in the damping chamber The piston 5 on the 4 is provided with a through hole communicating with the outside world in the buffer chamber 2; the damping chamber 3 is filled with water, and the piston 5 is provided with a fluid channel for water circulation. The shock absorber controls the opening and closing of the fluid channel through the one-way valve 6 arranged on the piston 5, and uses the throttling effect of the one-way valve 6 on the water to realize the change of the damping of the shock absorber.

[0053] The shock absorber cylinder 1 is divided into a damping chamber 3 and a buffer chamber 2 by a slidable partition 9 , and the piston 5 is arranged at the free end of the piston rod 4 . A spring 10 is arranged in the buffer chamber...

Embodiment 2

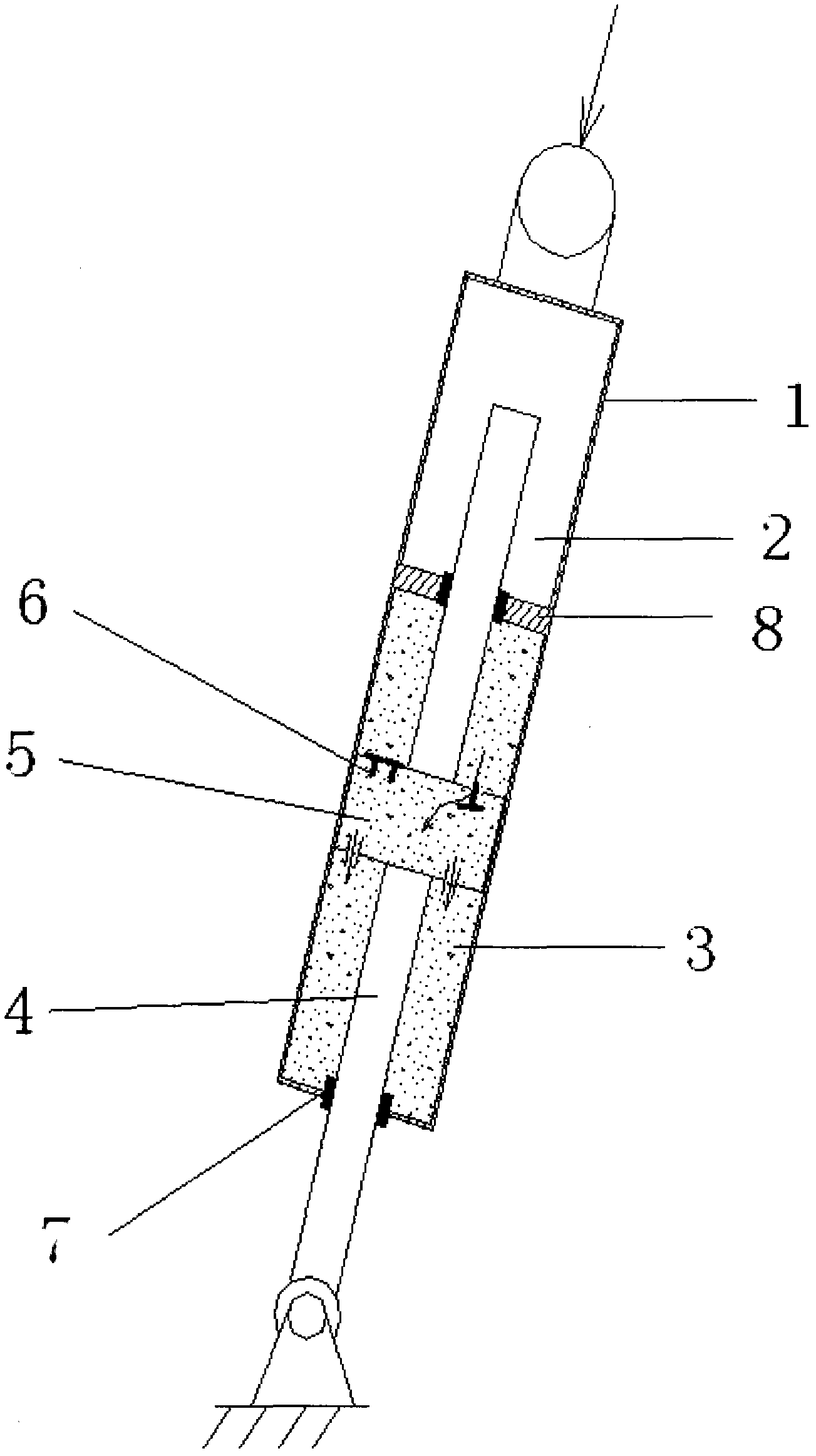

[0056] Such as image 3 The fluid variable damping shock absorber shown includes: a shock absorber cylinder 1 composed of a damping chamber 3 and a buffer chamber 2; a piston rod 4 inserted into the cylinder 1; a piston rod fixedly arranged in the damping chamber The piston 5 on the 4 and the buffer chamber 2 are provided with a through hole communicating with the outside world; the damping chamber 3 is filled with oil, and the piston 5 is provided with a fluid channel for oil circulation. The shock absorber controls the opening and closing of the fluid channel through the one-way valve 6 arranged on the piston 5, and uses the throttling effect of the one-way valve 6 on the oil to realize the change of the damping of the shock absorber.

[0057]The shock absorber cylinder 1 is divided into a damping chamber 3 and a buffer chamber 2 by a partition ring 8 fixed on the side wall of the cylinder 1 and sleeved on the piston rod 4. The free end of the piston rod 4 extends into the b...

Embodiment 3

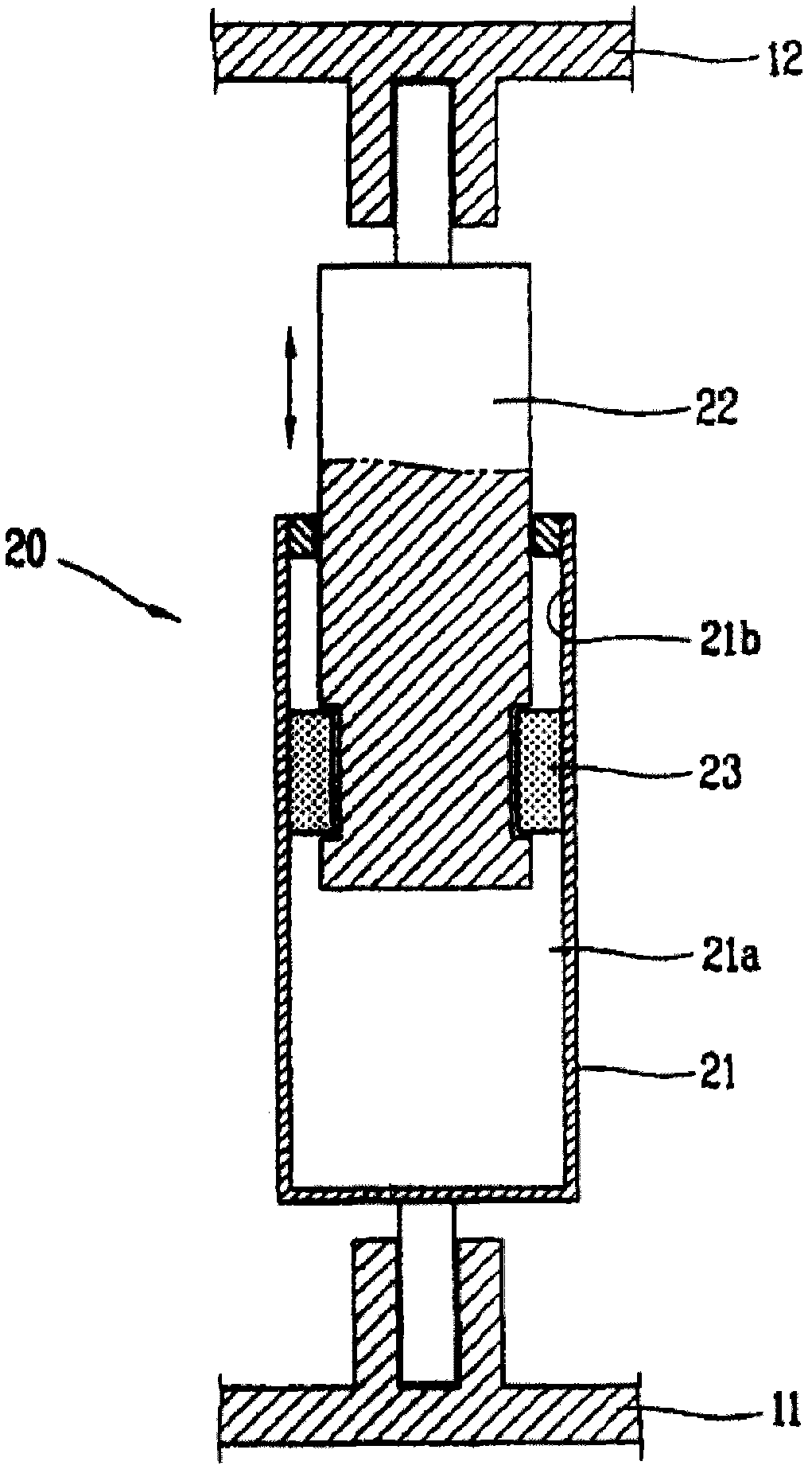

[0060] Such as Figure 4 The shown fluid variable damping shock absorber includes: a shock absorber cylinder 1 composed of a damping chamber 3 and a buffer chamber 2; a piston rod 4 inserted into the cylinder 1; a piston rod fixedly arranged in the damping chamber The piston 5 on the 4 and the buffer chamber 2 are provided with a through hole communicating with the outside world; the damping chamber 3 is provided with a damping medium, and the piston 5 is provided with a fluid passage for the damping medium to circulate. The shock absorber controls the opening and closing of the fluid passage through the one-way valve 6 arranged on the piston 5, and the change of the damping of the shock absorber is realized by the throttling effect of the one-way valve 6 on the damping medium.

[0061] The shock absorber cylinder 1 is composed of a damping cavity shell 12 and a slidable buffer cavity shell 11 sleeved outside the end of the damping cavity shell 12. Buffer chamber 2; a damping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com