Double curvature plate cold press forming method and equipment thereof

A cold-press forming, double-curvature technology, used in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of sheet thickness, large radius of curvature, high strength, and achieve smooth curve forming and high-quality pressing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

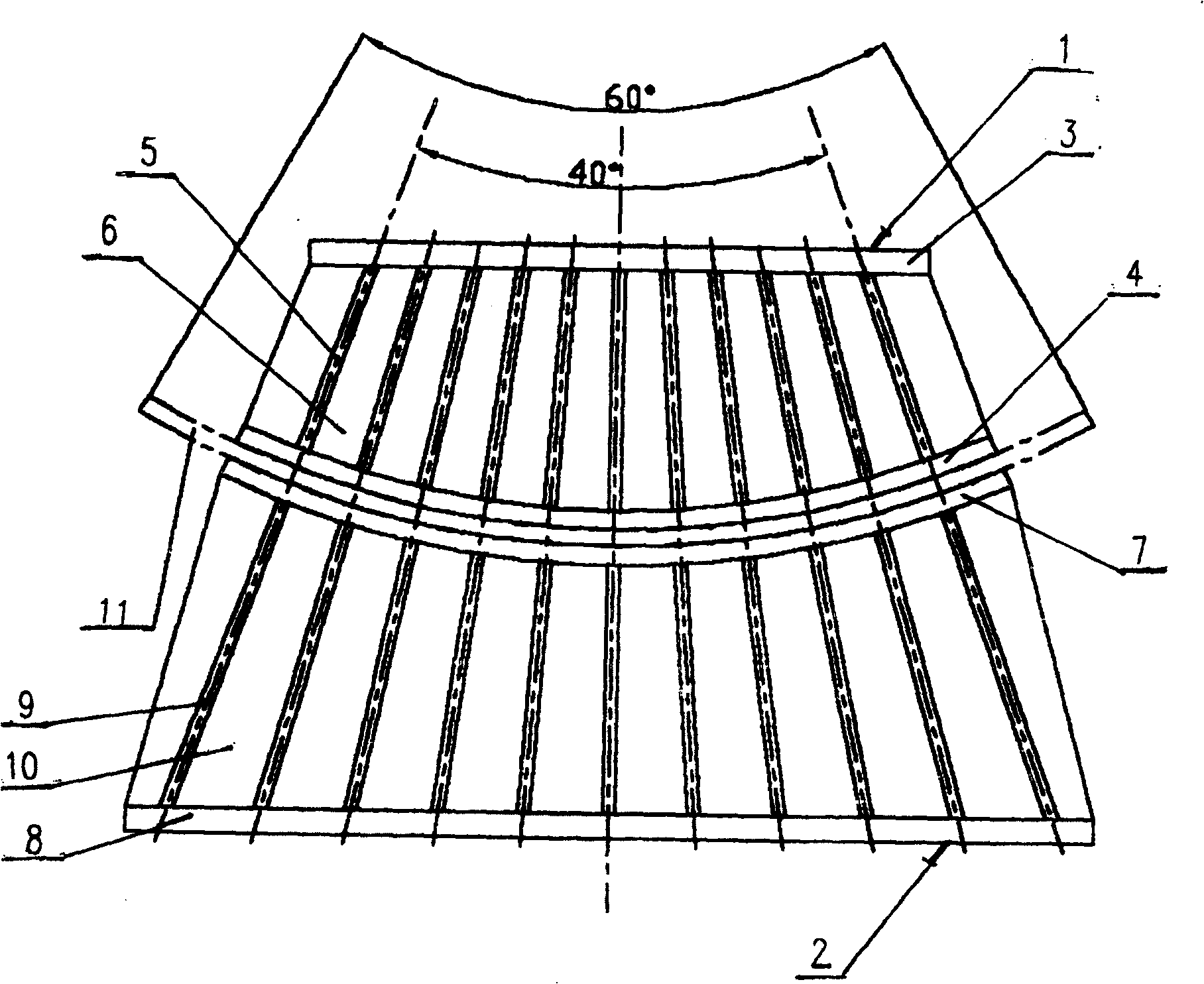

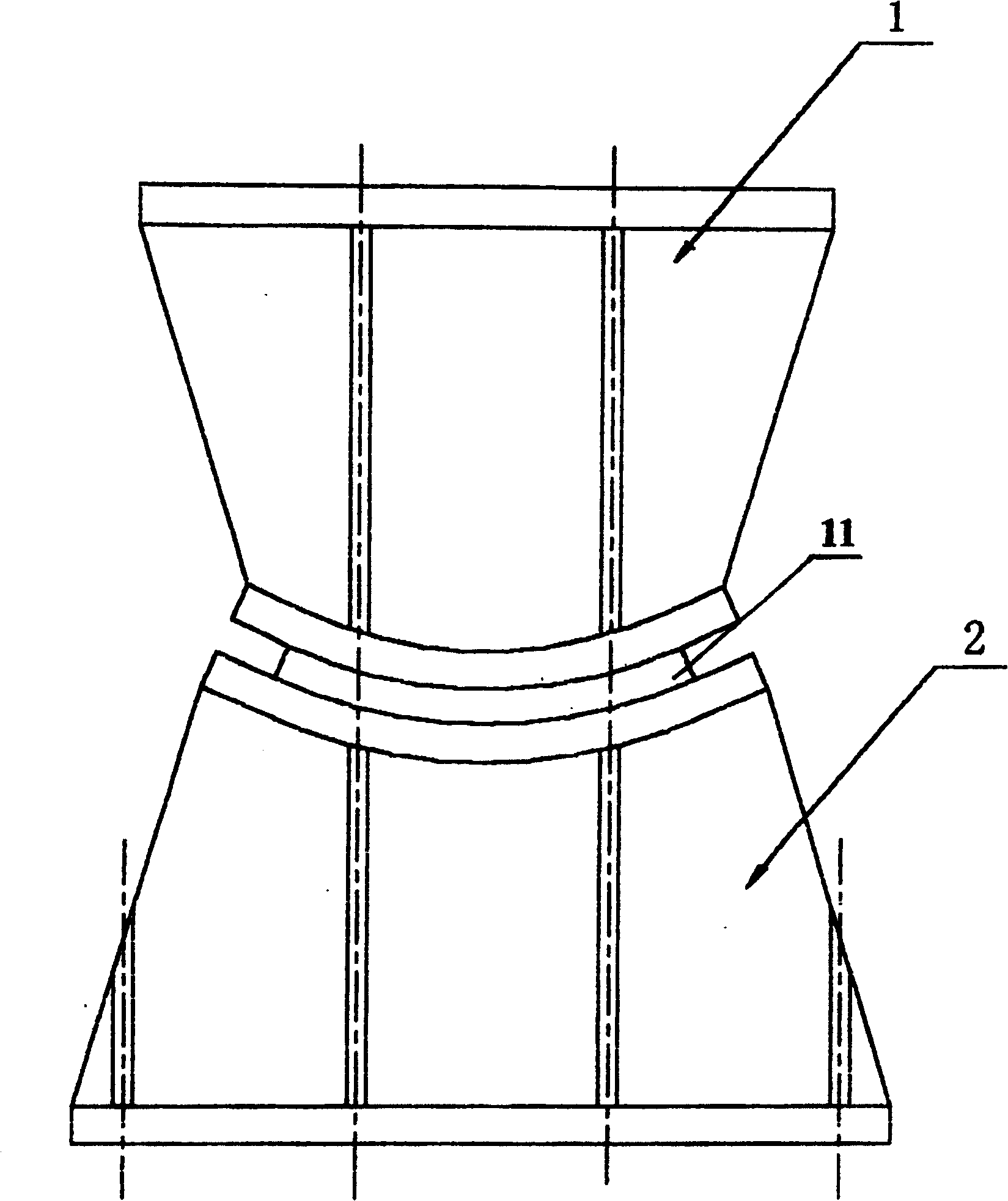

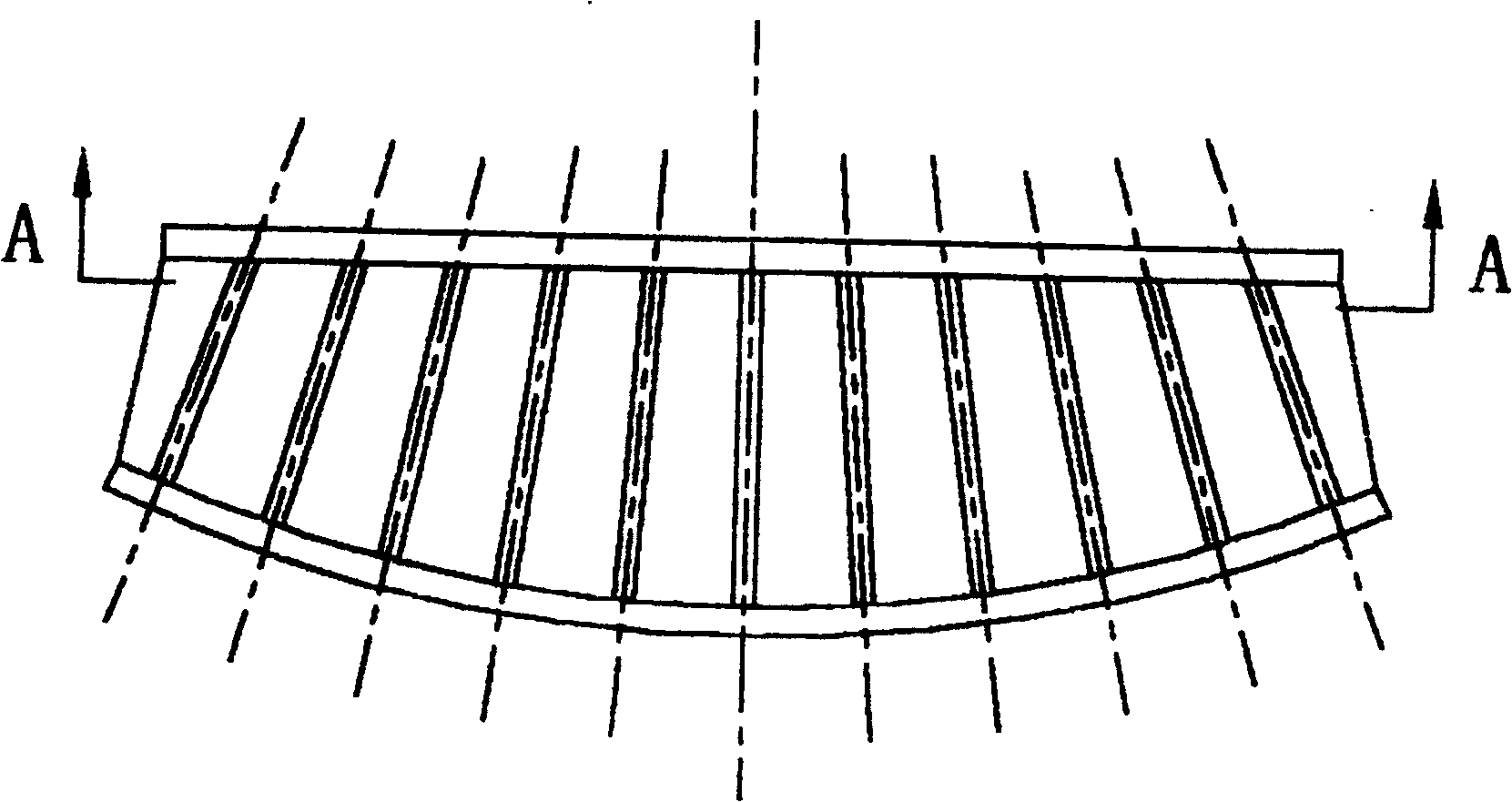

[0033] A 300-ton converter shell is fabricated by using double-curvature plate cold-press forming method and device. The structure of the double-curvature part on the furnace shell is shown in Figure 7 , Figure 8 . All dimensions referred to are in millimeters. The radius of curvature of the upper mouth of the converter shell is 4050, the radius of curvature of the lower mouth is 4250, the radius of curvature of the middle part is 1500, the height is 793, and the plate thickness is 85. The circumference of the whole circle is 25434 and pressed according to the six equal parts of the whole circle. The arc length of each workpiece is 4240 and the included angle is 60°.

[0034] According to the process, first take 1 / 12 of the double-curvature plate of the same material as the converter shell as the test plate. The test plate is 2120 long, 800 wide, and 85 thick. Take a test plate of good size and use the tire with the same curvature as the furnace shell. The tool is pressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com