An improved automobile laminated glass furnace outer pressing mold

A laminated glass and press molding technology, which is applied in glass molding, glass reshaping, glass manufacturing equipment, etc., can solve the deviation and fluctuation of optical performance and matching degree, the large change of curvature of side profile, and the side refraction of products And other problems, to achieve the effect of long molding time, improve the quality of the surface, and improve the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

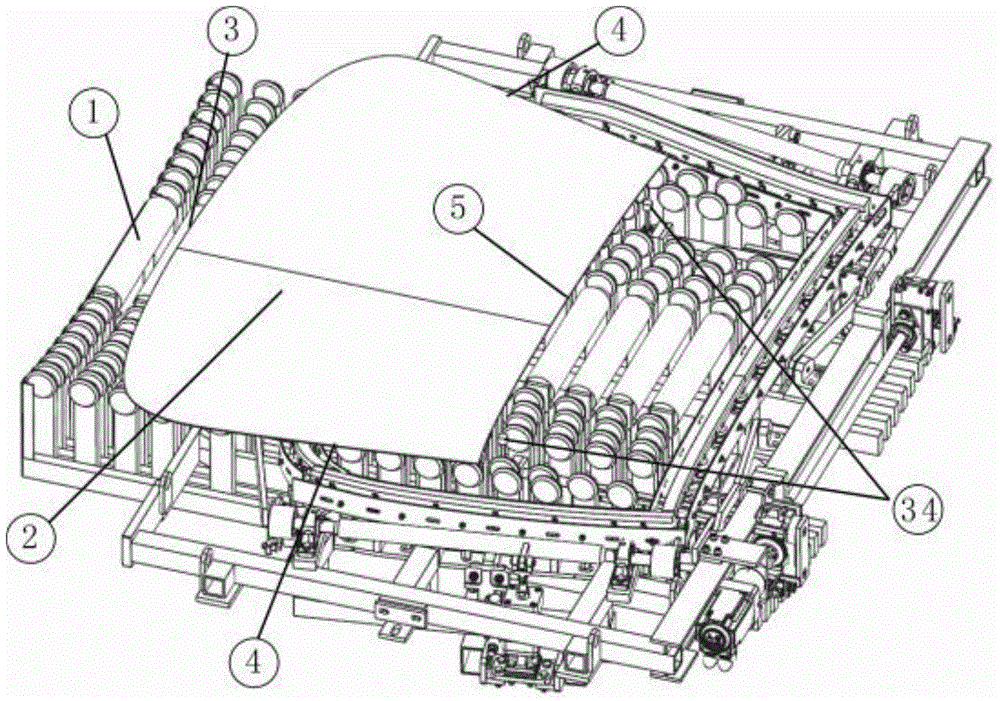

[0020] An improved automobile laminated glass furnace external press molding mold, including:

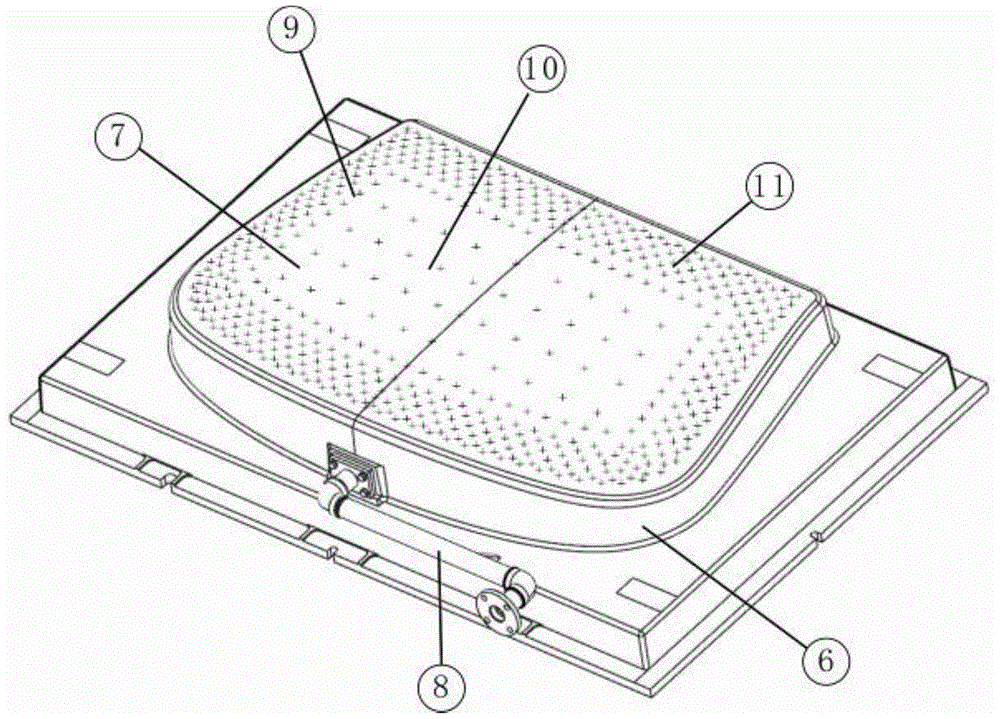

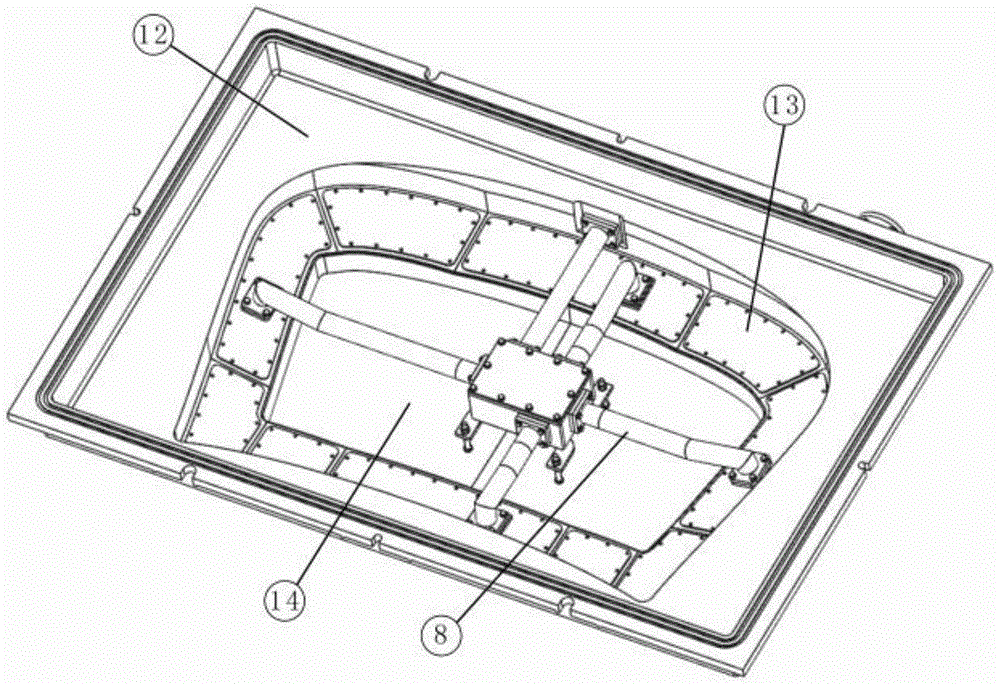

[0021] Punch 6, its structure is as Figure 2-3 As shown, the convex mold 6 includes a convex mold frame, and a convex block that protrudes upward on the convex frame to match the shape of the glass. The surface of the convex block is a convex mold surface 7, and the convex mold surface 7 It includes the inner cavity profile 10 of the punch at the center, and the outer cavity profile 11 of the punch set on its periphery, and the air holes 9 for vacuuming are provided on the convex mold surface 7, wherein the inner cavity profile of the punch 10 The lower cavity is the punch forming inner cavity 13, the outer cavity surface of the punch 11 is the punch forming outer cavity 14, and the rest of the lower cavity of the punch frame is the punch heating cavity mold 12, which is formed in the punch The inner cavity 13 and the male molded outer cavity 14 are provided with a convex mold sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com