Front-mounted broadened aluminum profile extruding die

A technology for extrusion dies and aluminum profiles, applied in the direction of metal extrusion dies, etc., can solve problems such as troublesome installation and user inconvenience, and achieve the effects of reducing extrusion force, prolonging service life, and improving profile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

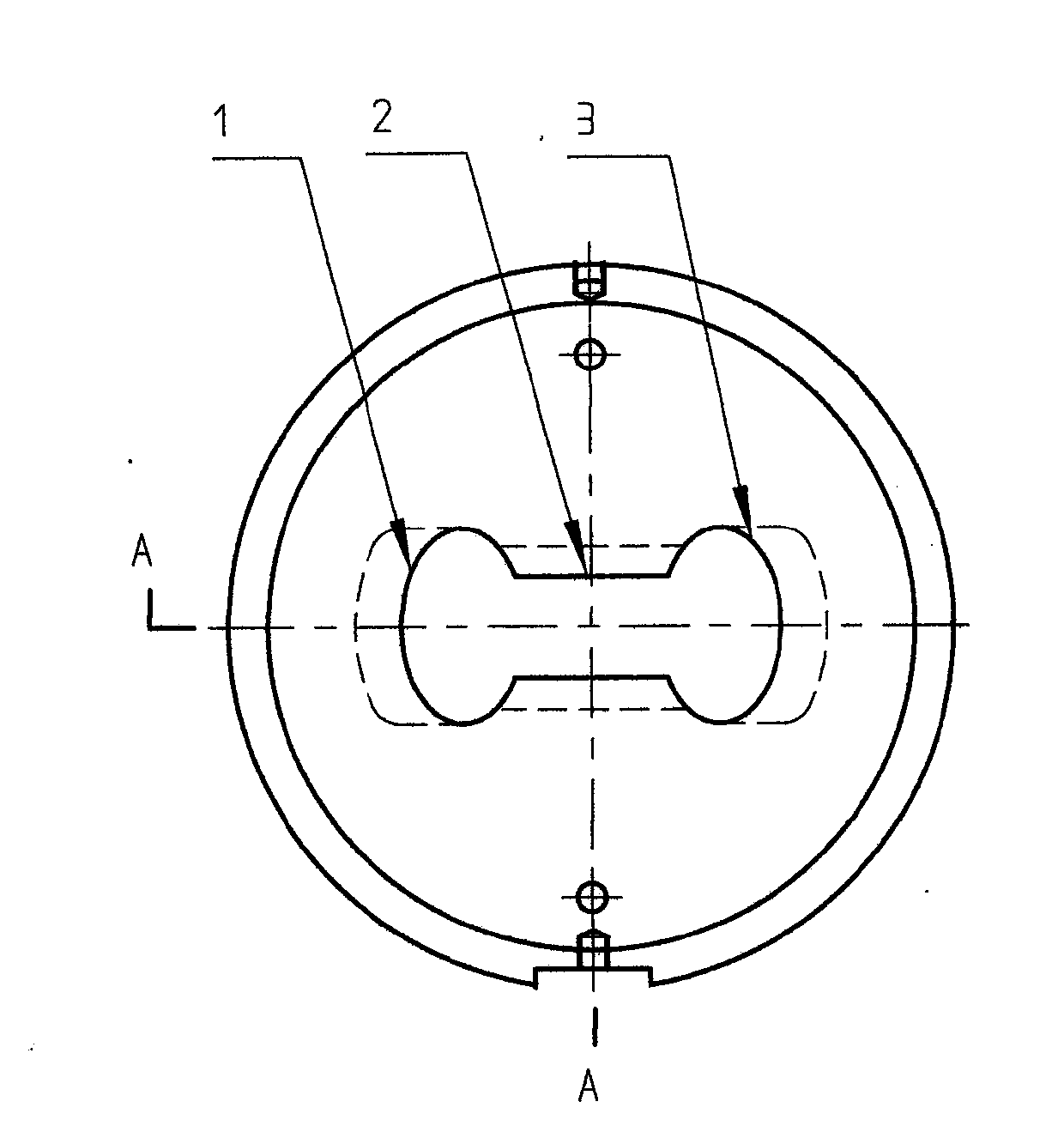

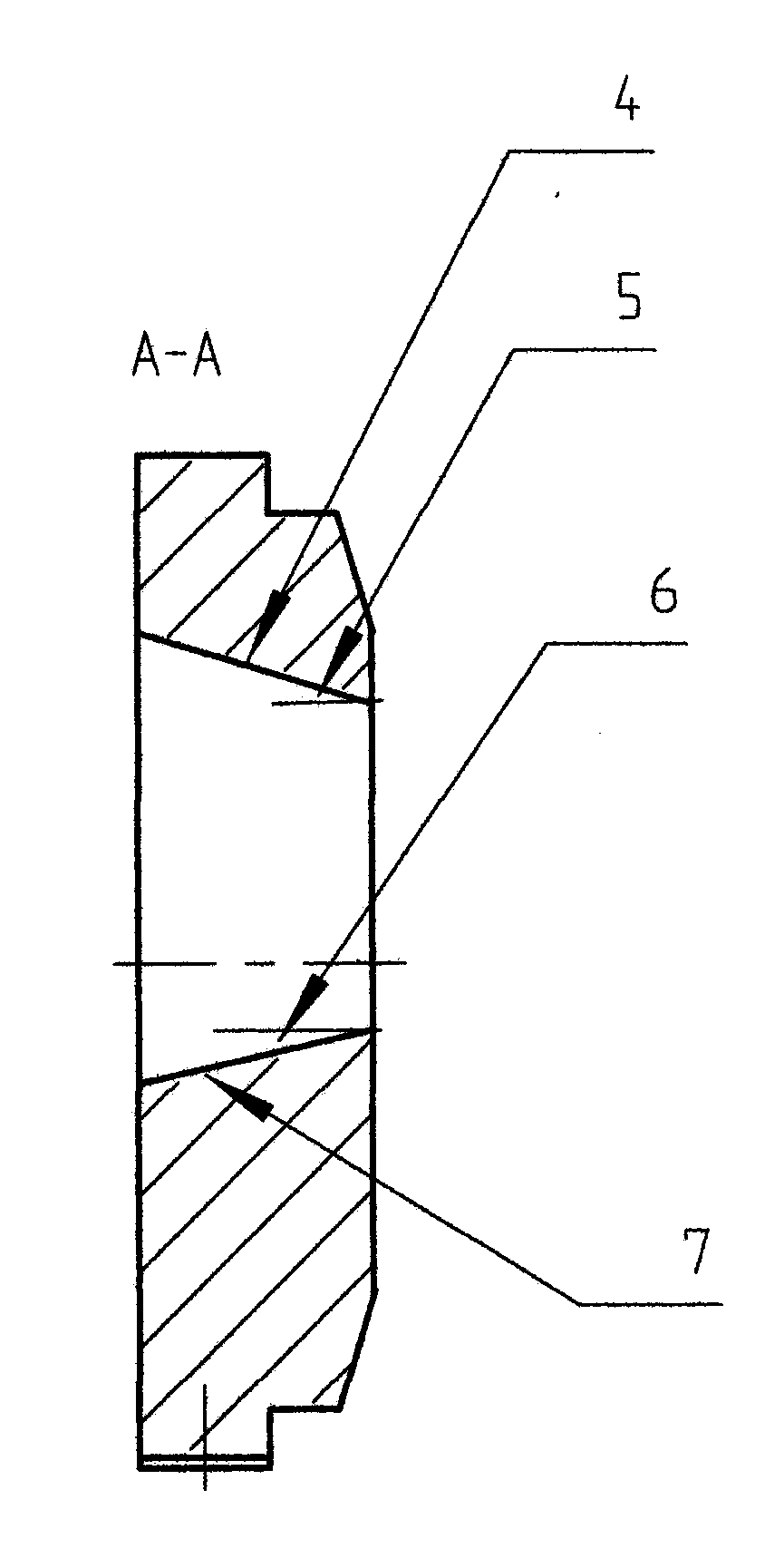

[0013] exist Figure 1-Figure 2 Among them, the front widening aluminum profile extrusion die is composed of a circular extrusion cylinder, a widening die, and a forming die. The widening die is placed in front of the forming die, and the middle part (2) of the cavity is larger than the left and right ends of the cavity (1, 3) narrowed by 25%-40%. The expansion angles (5) formed by the left and right end taper surfaces (4) of the die cavity and the axis of the front wide aluminum profile extrusion die are both 18-25°. The pressure relief angles (6) formed by the upper and lower tapered surfaces (7) and the axis of the die cavity of the front wide aluminum profile extrusion die are both 10-20°. In the extrusion process of this structure, when the end of the ingot flows into the center of the front wide expansion die, it does not flow out of the forming die immediately, but flows to both ends according to the principle of least resistance, balancing the pressure of the center a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com