Under-driven tension-controllable net stretching clamp and use method thereof

A technology of tension and stretching, which is applied to screen printing machines, printing, rotary printing machines, etc. It can solve the problems of not being able to use the tension of the screen and affecting the stretching effect, and achieve uniform tension, good stretching effect, and reliable clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

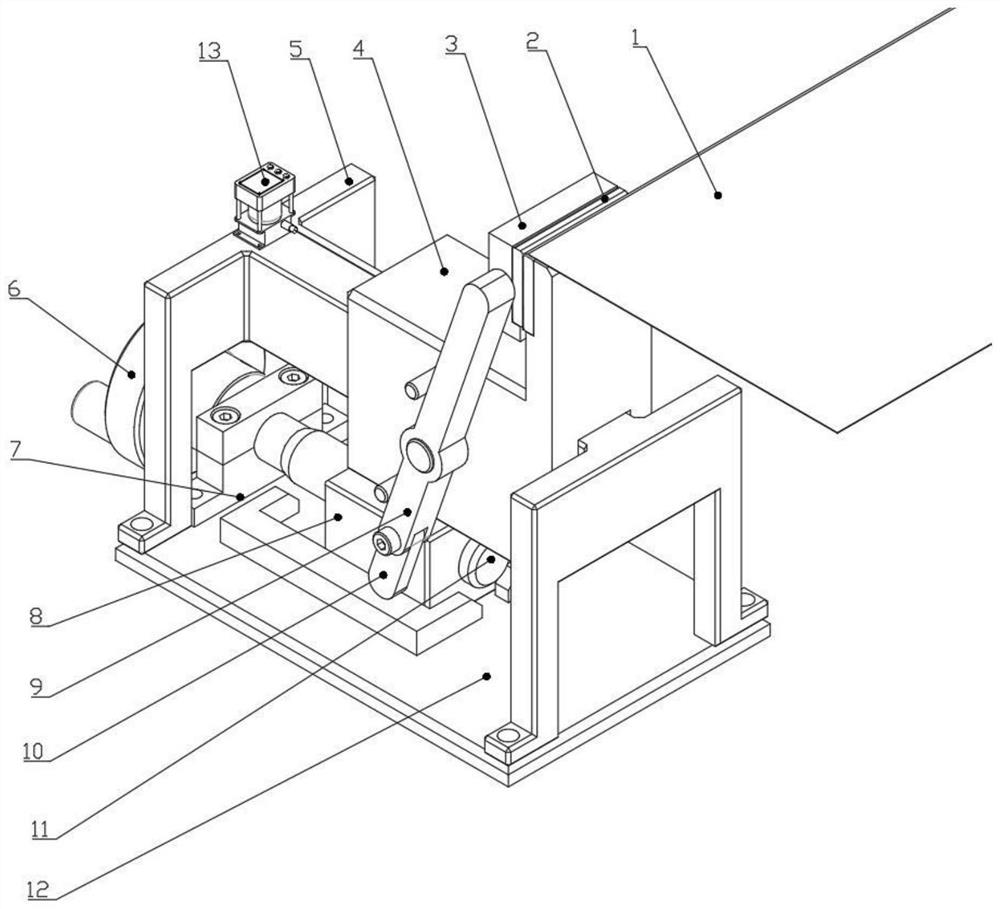

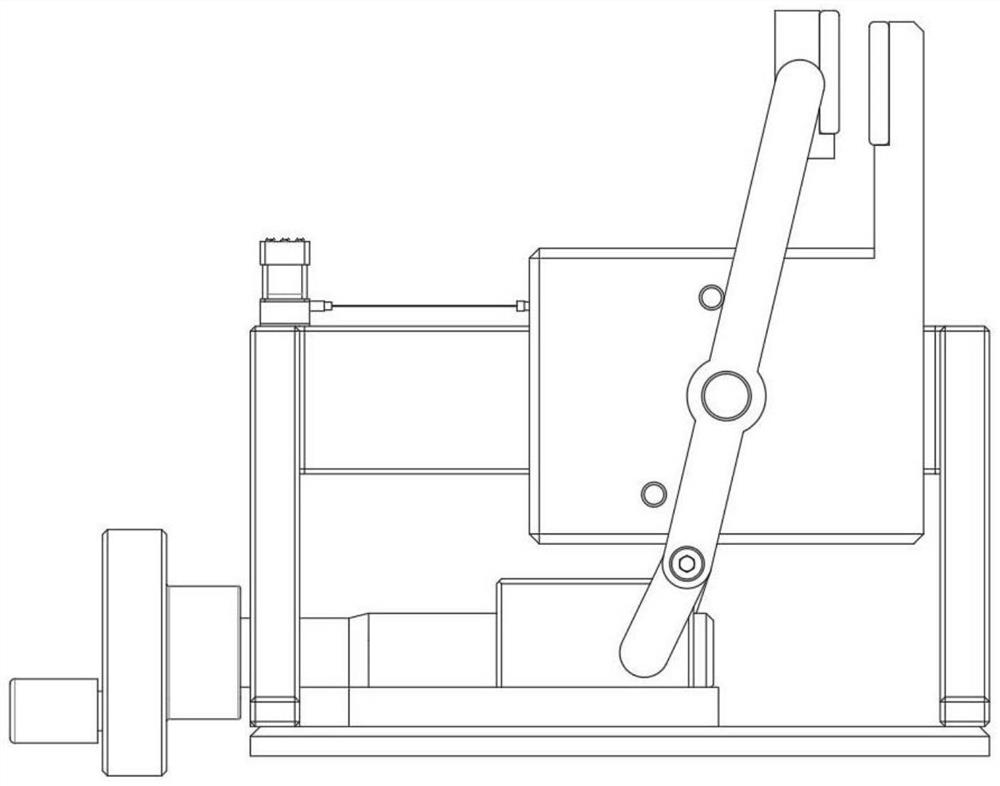

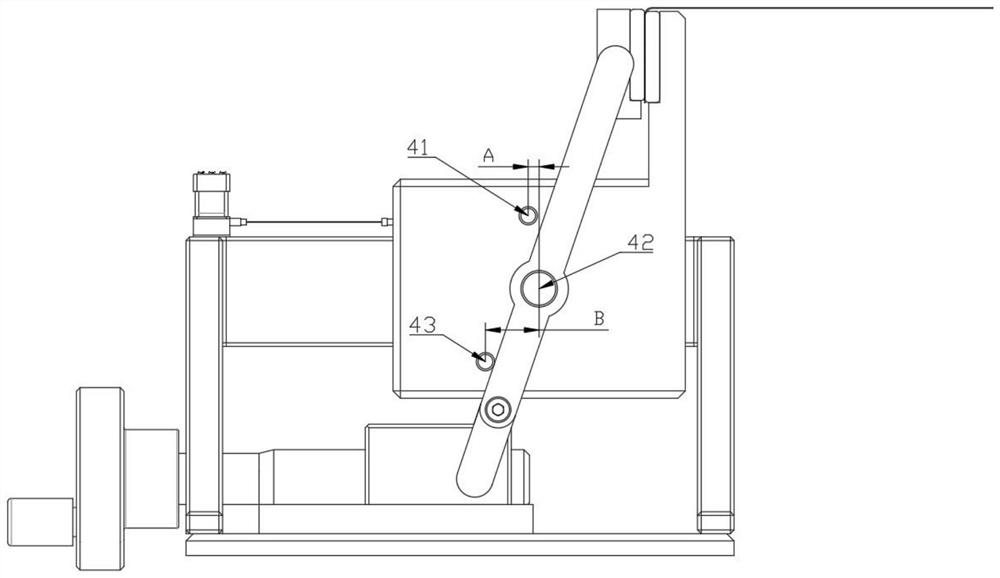

[0035] Embodiment 1: as Figure 1-13 As shown, an under-driven tension controllable stretching net clamp includes a driving module 6, a first moving module, a second moving module, a rotating module, a rotating limiting module, a first clamping body 3, and a moving limiting module The drive module 6 is connected with the first mobile module, and the first mobile module is driven by the drive module 6 to move; the rotation module is connected with the first mobile module, the second mobile module, and the first clamping body 3: the first mobile module The movement of the rotating module drives the rotation of the rotating module, and the rotation of the rotating module drives the first clamping body 3 to move in the opposite direction to the first moving module; The second moving module moves in the same direction as the first moving module; the movement limiting module is used to limit the movement of the first moving module.

[0036] Further, a tension display module 13 may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com